Gapless expansion and retraction reel with automatic clamping function

An automatic clamping and expansion-shrinking reel technology, applied in the field of seamless expansion-shrinking reels, can solve problems affecting the quality of sheet metal rolling, and achieve the effect of convenient maintenance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

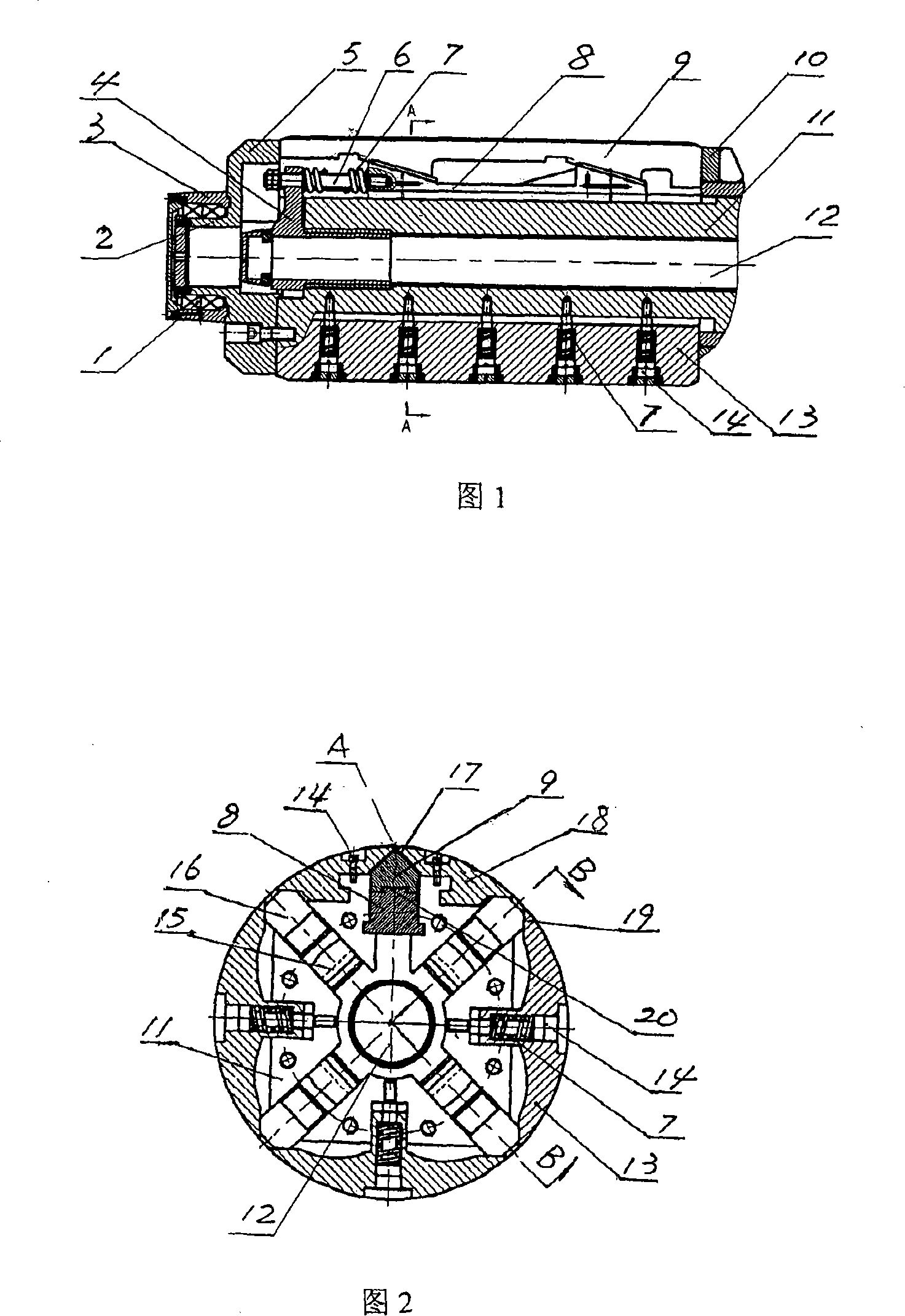

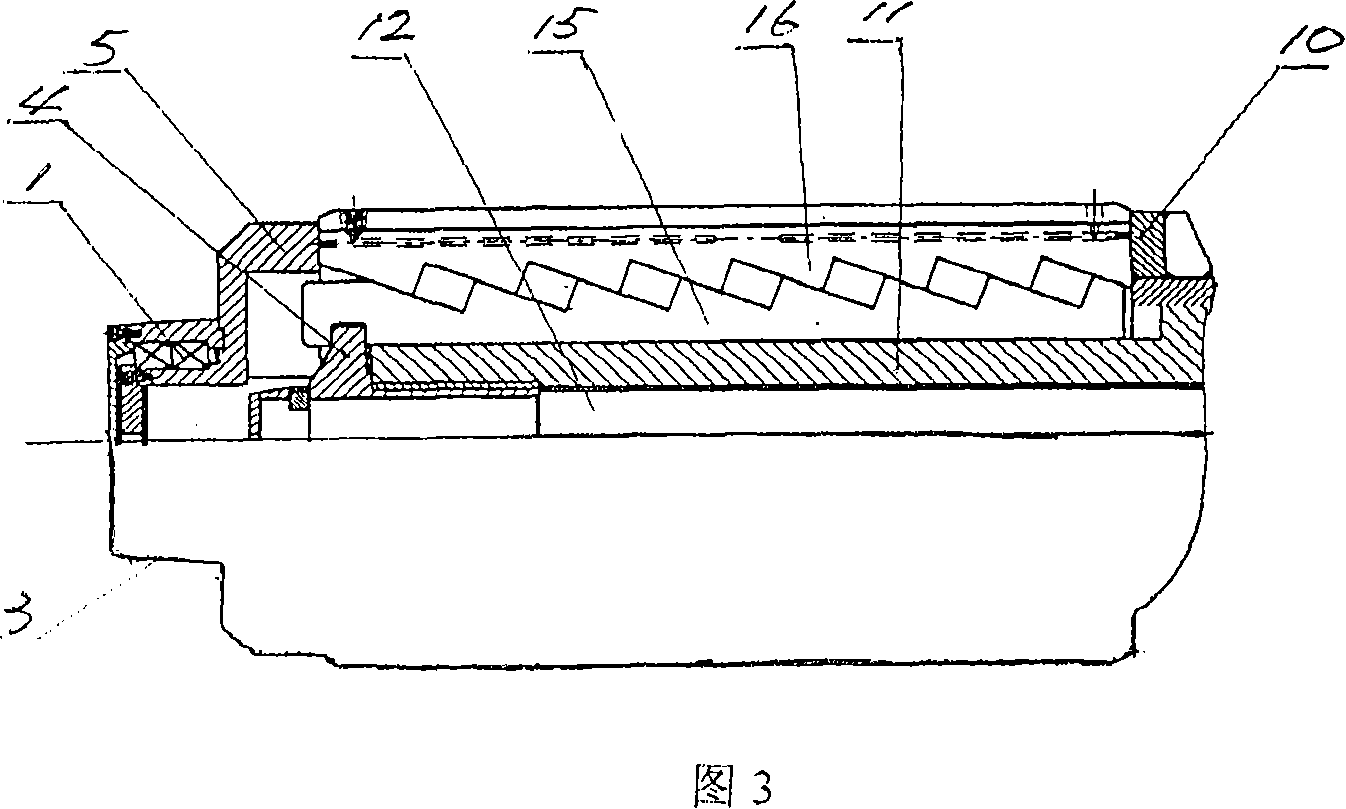

[0016] As shown in Fig. 1, Fig. 2 and Fig. 3, the seamless expansion and contraction reel with automatic clamping function of the present invention contains a main shaft 11, and a central hole is processed in the main shaft 11, and a moving shaft 12 is arranged in the central hole, and the center There is a sliding fit between the hole and the moving shaft 12. The cross section of one section of the front end of the main shaft 11 is a square, and three faces of the section are provided with an arc plate 13, and the main shaft 11 at the rear end of the arc plate 13 is fixed with a retaining sleeve 10 for blocking the arc plate 13. Axial grooves are processed on the four corners of the front section of the main shaft 11 in the longitudinal direction, and an axial tooth plate 15 is installed in each axial groove, and the axial tooth plate 15 and the axial groove are in a sliding fit. The front end of the axial gear plate 15 protrudes outside the front end of the main shaft 11 . ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com