Method and device for braking the rotor of a wind energy plant

A technology of wind power equipment and driving devices, which is applied in the control of wind power engines, mechanical equipment, wind power engines, etc., can solve the problems of high assembly and operation costs, and achieve the effect of reliable interruption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

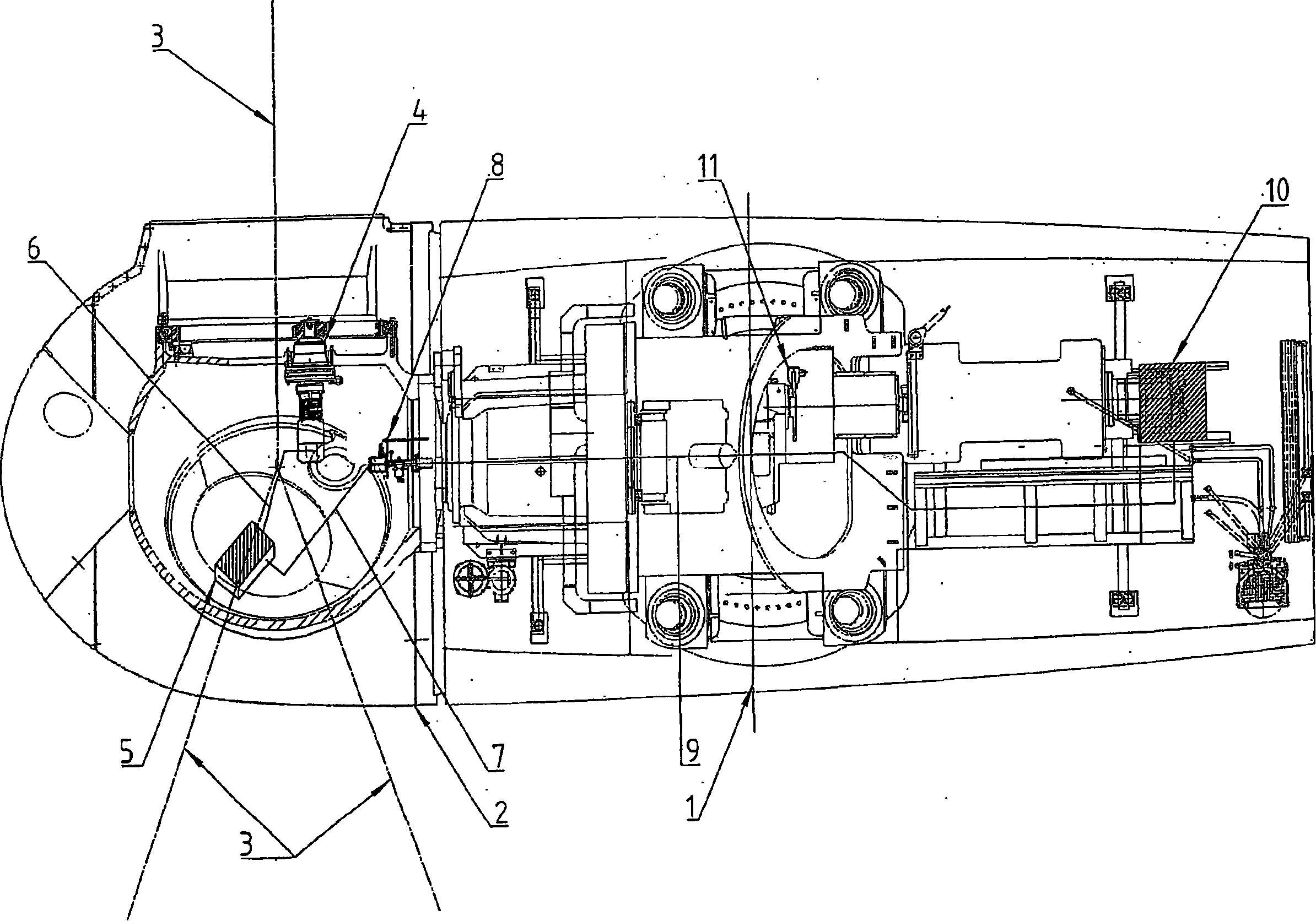

[0011] The figure schematically depicts a nacelle 1 of a wind power plant, on which a hub 2 is rotatably mounted. A schematically depicted rotor blade 3 is rotatably mounted on the hub 2 via its axis of rotation. In order to rotate the rotor blades 3 , each rotor blade 3 is provided with a drive consisting of an electric motor 4 and a frequency converter 5 . Each electric motor 4 is equipped with a lock which, in the activated state, prevents the rotor blade 3 from rotating into the operating position, but allows the rotor blade 3 to rotate continuously or discontinuously into the sail position. In the inactive state the lock is inactive, ie rotation of the rotor blade 3 in all directions is possible. The lock can be designed and operated as described in WO 99 / 23384 A1, for example. However, the lock can also be designed in such a way that it catches and blocks the rotor blades 3 only in the sail position, so that they rotate back into the operating position.

[0012] Each ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com