Compound vacuum precompressed soft foundation comprehensive strengthening method

A vacuum and preloading technology, which is applied in the field of soft soil foundation reinforcement and large-area deep soft soil foundation reinforcement. The effect of increasing the time of pressing, increasing the permeability coefficient, and increasing the impact energy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

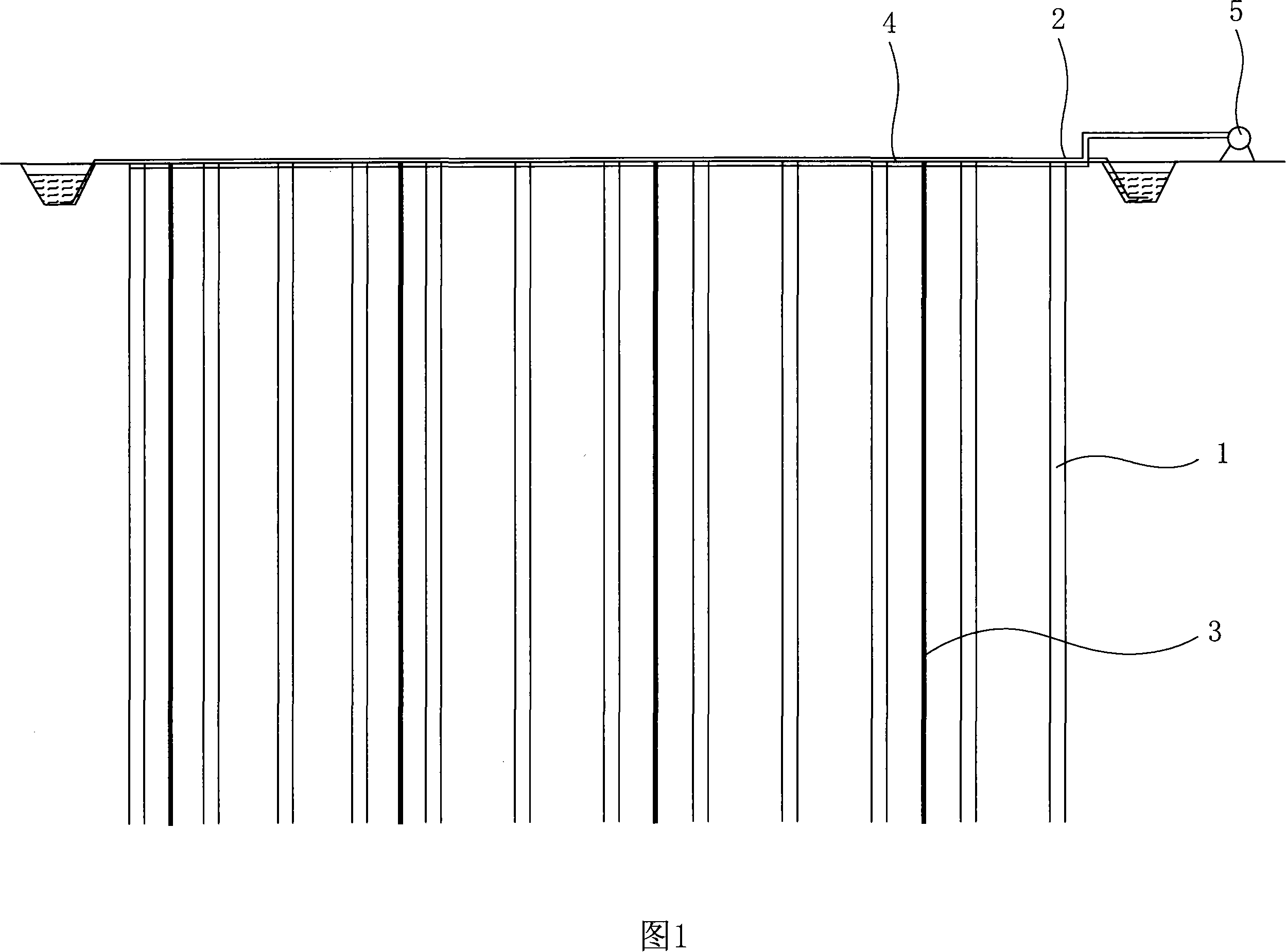

[0036] Embodiment 1: Referring to Figure 1, a composite vacuum preloading soft foundation comprehensive reinforcement method, the method includes vacuum preloading dewatering and electroosmotic dewatering two parts, the construction steps are as follows:

[0037] a) Leveling the site and setting up a site drainage system; including a horizontal drainage system and a vertical drainage system, the horizontal drainage system is made up of drainage blind ditches, horizontal vacuum pipes 4 and sump wells, and the vertical drainage system is composed of plastic drainage boards and positive Negative electrode 2 composition.

[0038]Insert plastic drainage boards 1 on the site to be treated, the distance between plastic drainage boards is 1m×1m, and they are arranged in a plum blossom shape. Plastic drainage boards must use high-performance plastic drainage boards to ensure the mechanical strength required for smooth vacuum. Geotextiles to ensure the smooth drainage of the vacuum syst...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com