Rotary kiln inside lining refractory materials injecting brick with novel structure

A technology of refractory materials and new structure, applied in the direction of rotary drum furnace, furnace type, furnace, etc., can solve the problems of affecting the life of lining refractory materials, uneven expansion and displacement, loss of lifting effect, etc., to improve the kiln lining Longevity, reduced scouring wear, and enhanced integrity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

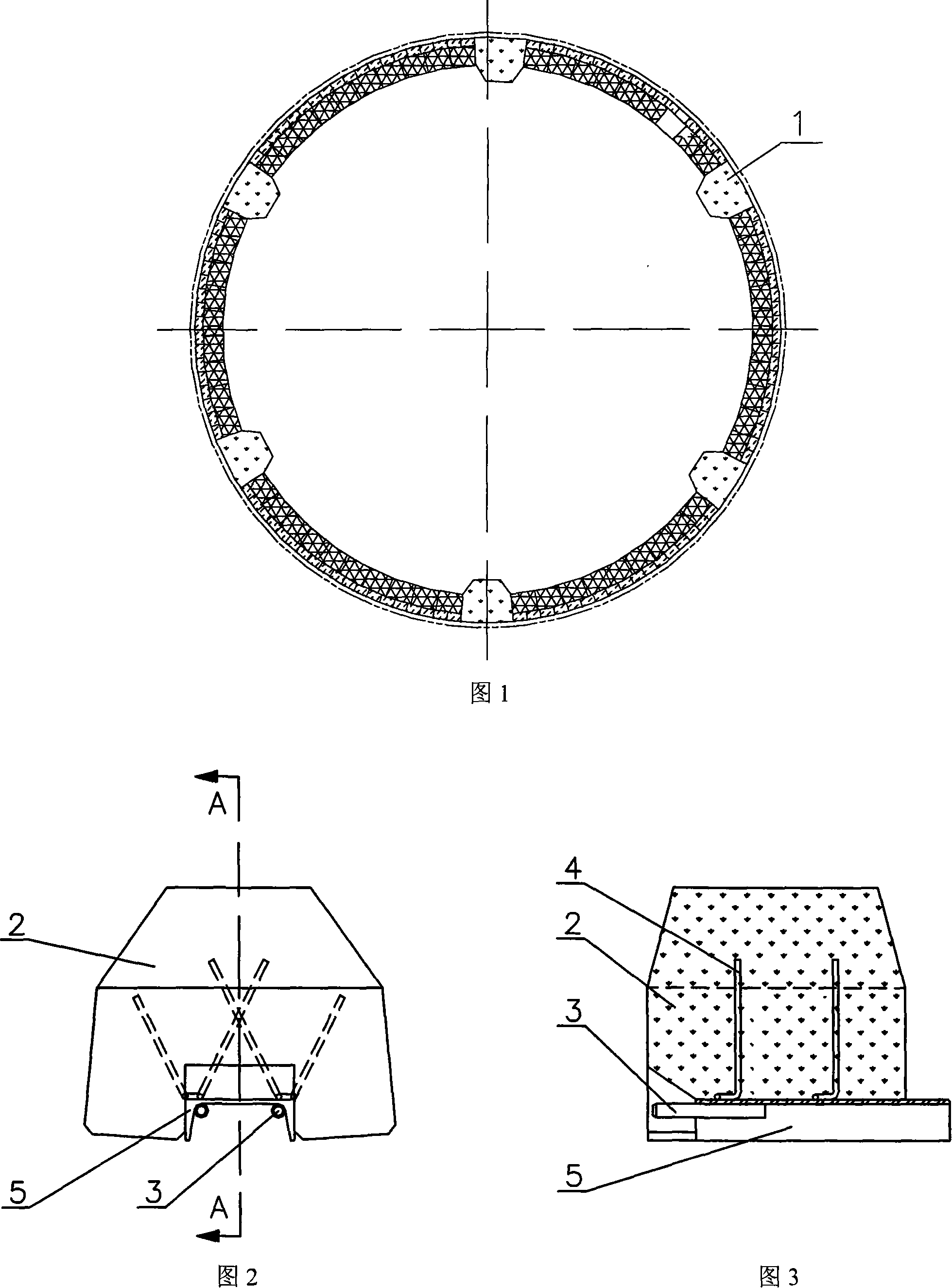

[0021] A new type of refractory-lined lifting brick for rotary kiln, see Figure 2 and Figure 3, cast refractory castable 2 on a metal structure frame according to the required specifications and sizes, see Figure 4, Figure 5, metal structure frame It includes the channel steel 5 used to weld the lifting brick on the rotary kiln shell 6 and the anchor piece 4 welded on the channel steel so that the channel steel 5 and the refractory castable 2 are integrated, as well as the channel steel 5 for welding It is an inlay rod 3 for inlaying two lifting bricks 1 together in the length direction of the rotary kiln. As shown in Figure 6, the anchor is made of heat-resistant stainless steel and is in the shape of a "V". The inlaid rod 3 is made of common material round steel. The lifting part of the lifting brick is poured into a square cone shape, which can reduce the erosion and wear of the material on the corners of the brick. The lifting brick formed by one-time casting with refract...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com