Sliding window pressure differential drainage system

A drainage system and sliding window technology, applied in the direction of condensed water discharge, wing fan layout, etc., can solve the problems of air filling, dust inflow, and watertight performance of sliding windows, etc., and achieve convenient use, low cost, and remarkable and reliable effect Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

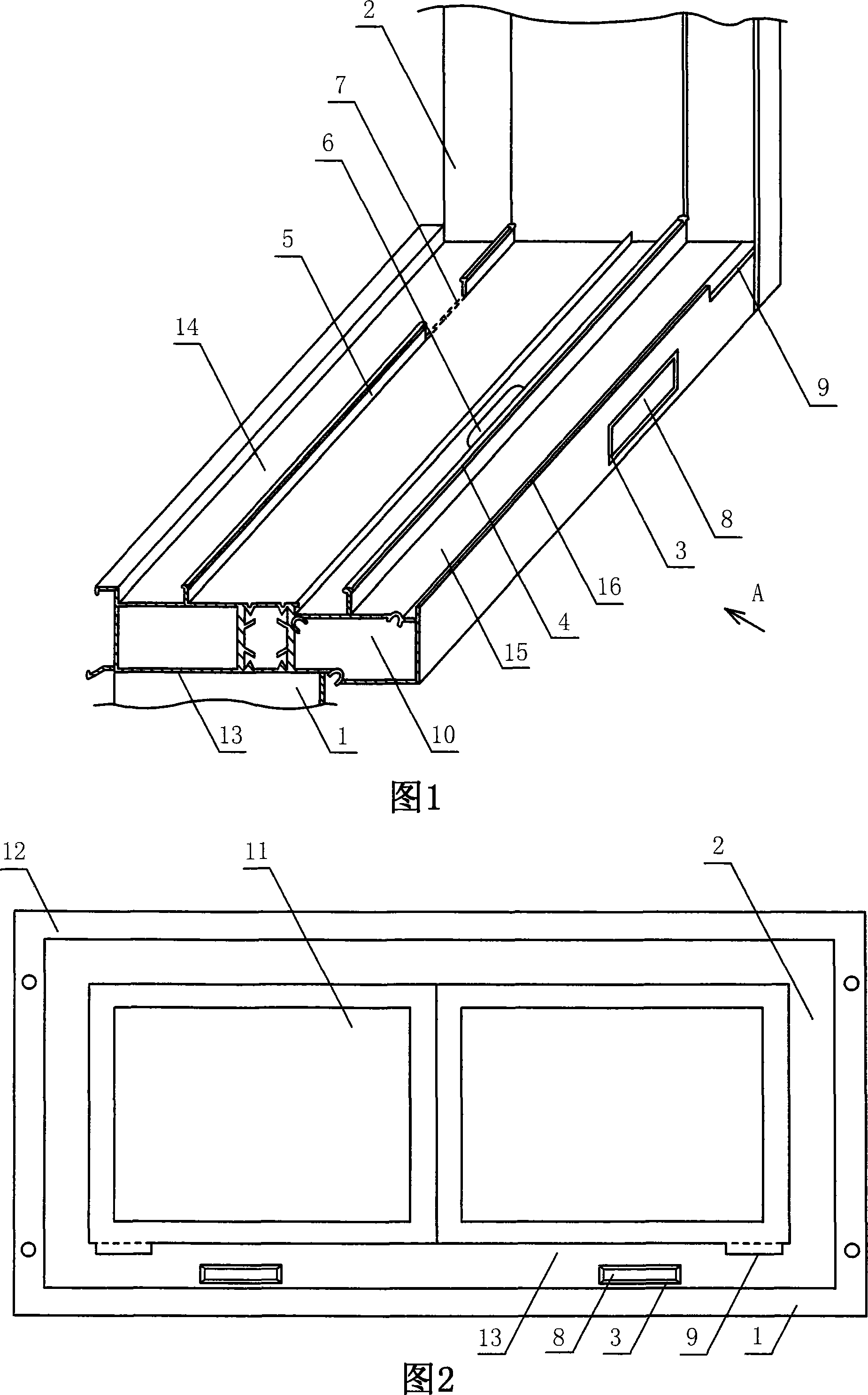

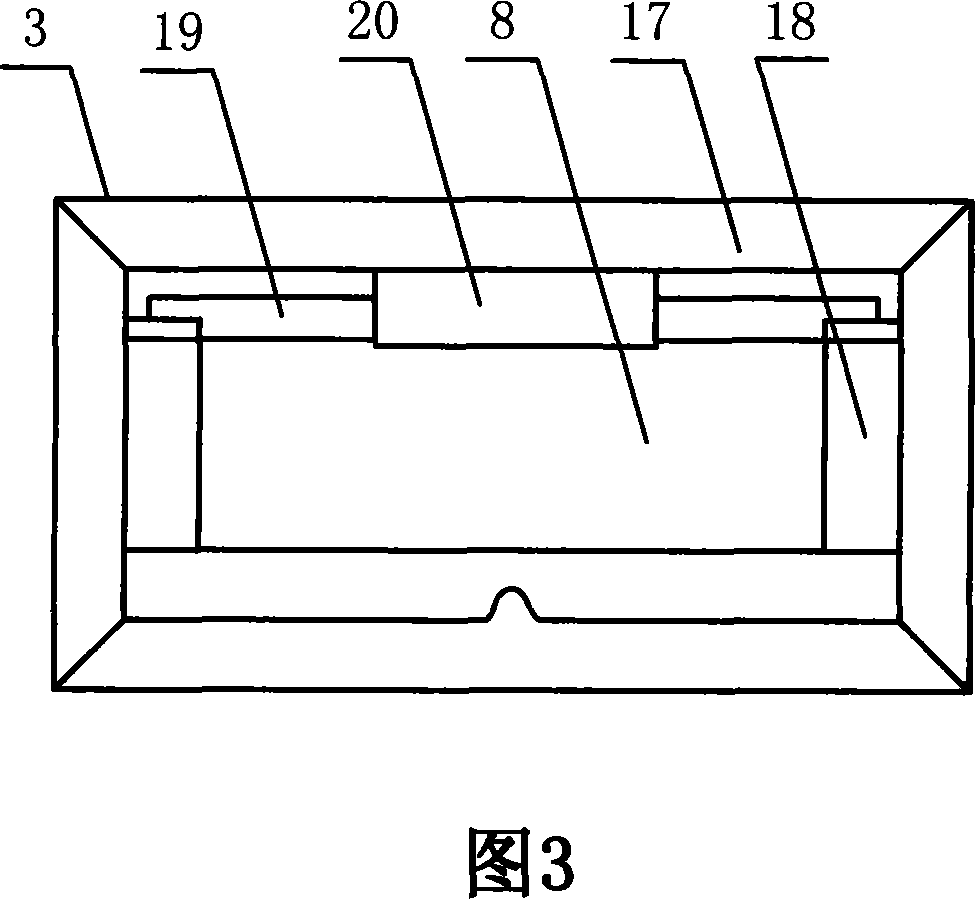

[0012] As shown in Fig. 1 and Fig. 2, the sliding window differential pressure drainage system of the present invention includes: a lower frame 1, a sliding bottom frame 13 installed on the lower frame, a sliding door and window sash 11, and drainage holes 6, wherein the The sliding bottom frame 13 includes an inner sliding bottom frame 14 and an outer sliding bottom frame 15 bottomed at the inner sliding bottom frame. The upper middle position of the inner sliding bottom frame 14 is provided with an inner slideway 5, and the inner slideway 5 is close to two Anti-collision block installation grooves 7 are respectively provided at the ends, through which the water accumulated on the inside of the inner slideway 5 can be discharged to the drainage hole 6 arranged on the outer sliding bottom frame 15, and the upper middle position of the outer sliding bottom frame 15 An outer slideway 4 is provided, and a screen window slideway 16 is provided on the outer side of the upper part of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com