Assembly technique for supporting plate and supporting rod of fuel oil dispensing pipe and clamp thereof

A technology for assembling fixtures and bracket rods, which is applied in the direction of fuel injection devices, charging systems, liquid fuel feeders, etc., can solve problems such as high prices, achieve the effects of reducing defective products, shortening adjustment time, and improving product quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

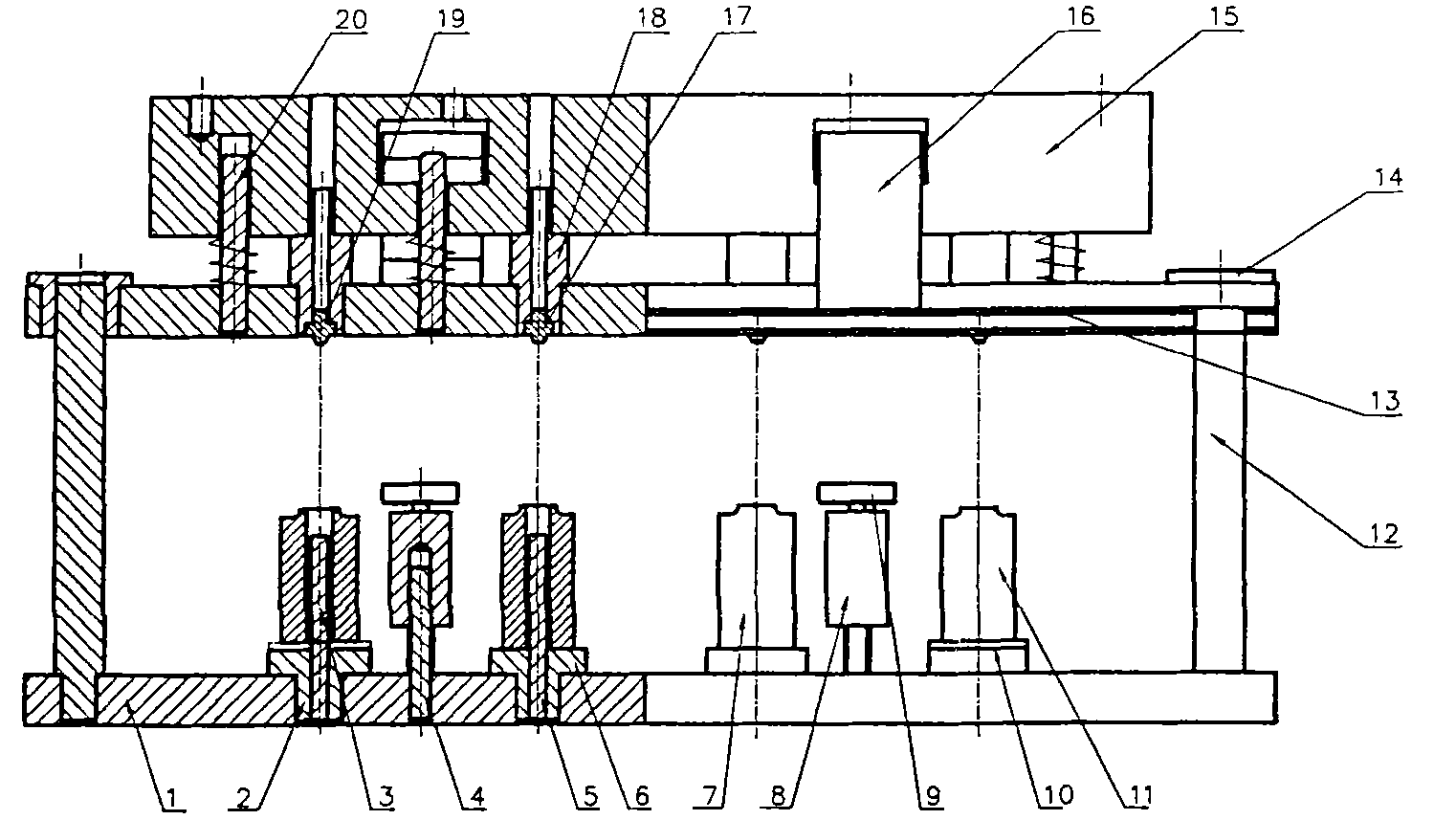

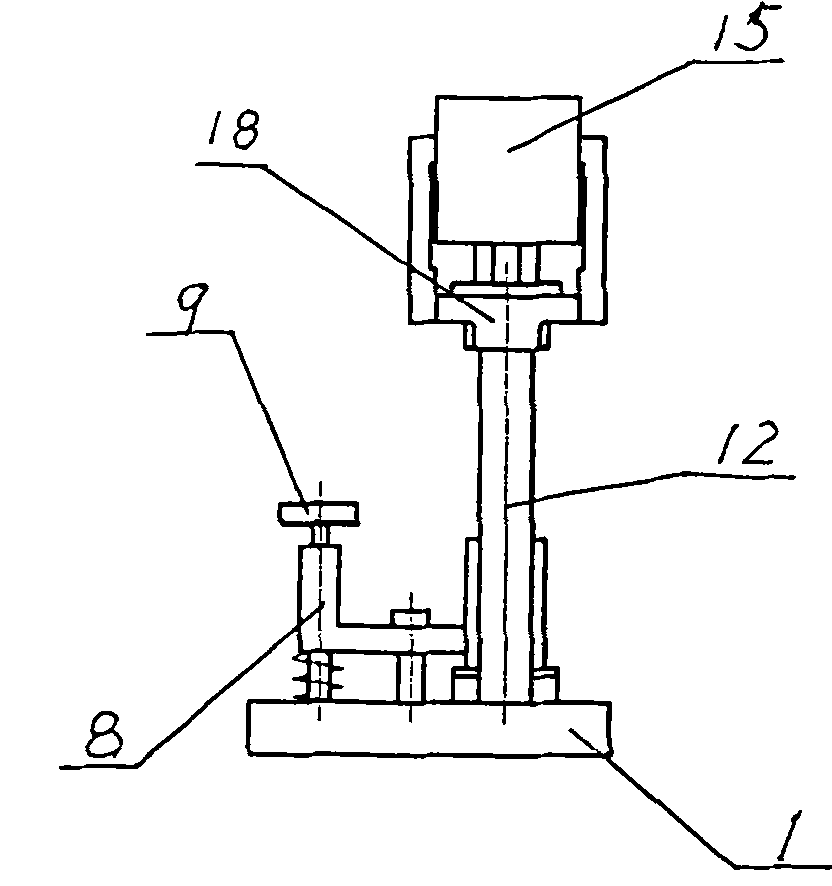

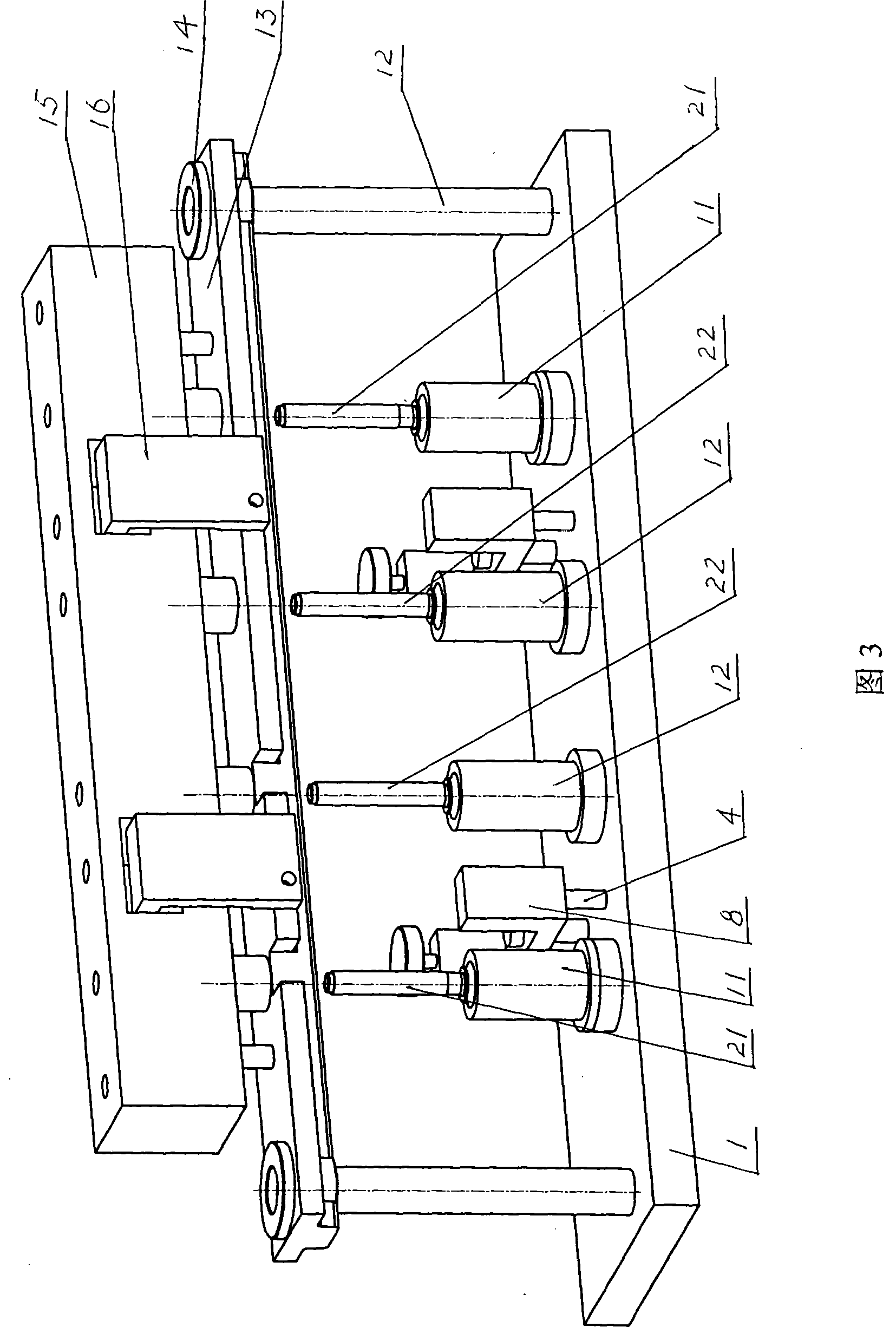

[0024] Such as figure 1 As shown, it is a structural schematic diagram of an assembly fixture for a fuel distribution pipe support plate and a support rod,

[0025] The assembly fixture of a fuel distribution pipe support plate and a support rod is composed of a bottom plate 1, an A cushion block 2, a first positioning pin 3 of the support rod, a first pin 4, a second positioning pin 5 of the support rod, and a B cushion block 6. Hole inner diameter 7mm height limit column 7, adjustable pad 8, fine-tuning screw 9, error prevention ring 10, hole inner diameter 6.4mm height limit column 11, guide column 12, moving pressure plate 13, linear bearing 14, pressure block 15, auxiliary Hook 16, A pressure head 17, pressure head connecting rod 18, B pressure head 19 and the second pin 20 form.

[0026] Assemble the two A pads 2 and B pads 6 into the holes of the bottom plate 1 respectively, and the two A pads 2 are respectively arranged on both sides of the two B pads 6, and the first...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com