Method for preparing plate-patched cross-column

A technology of cross columns and webs, which is applied in the field of plate-jointed cross-column preparation, can solve the problems of large welding deformation, small workload, small deformation of plate-jointed cross columns, etc., achieves small combined deformation, improves production efficiency, Effect of Twist Guarantee

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

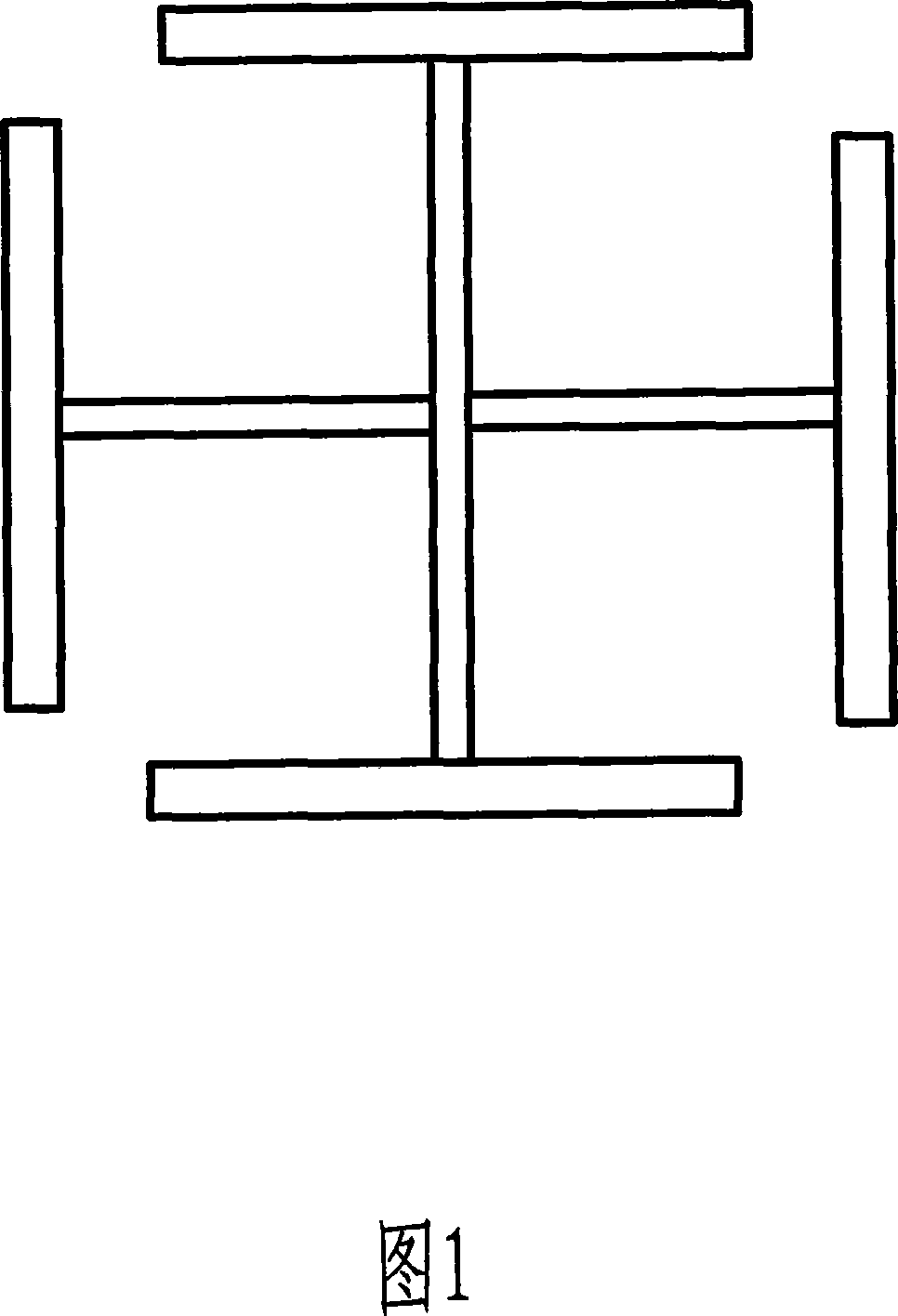

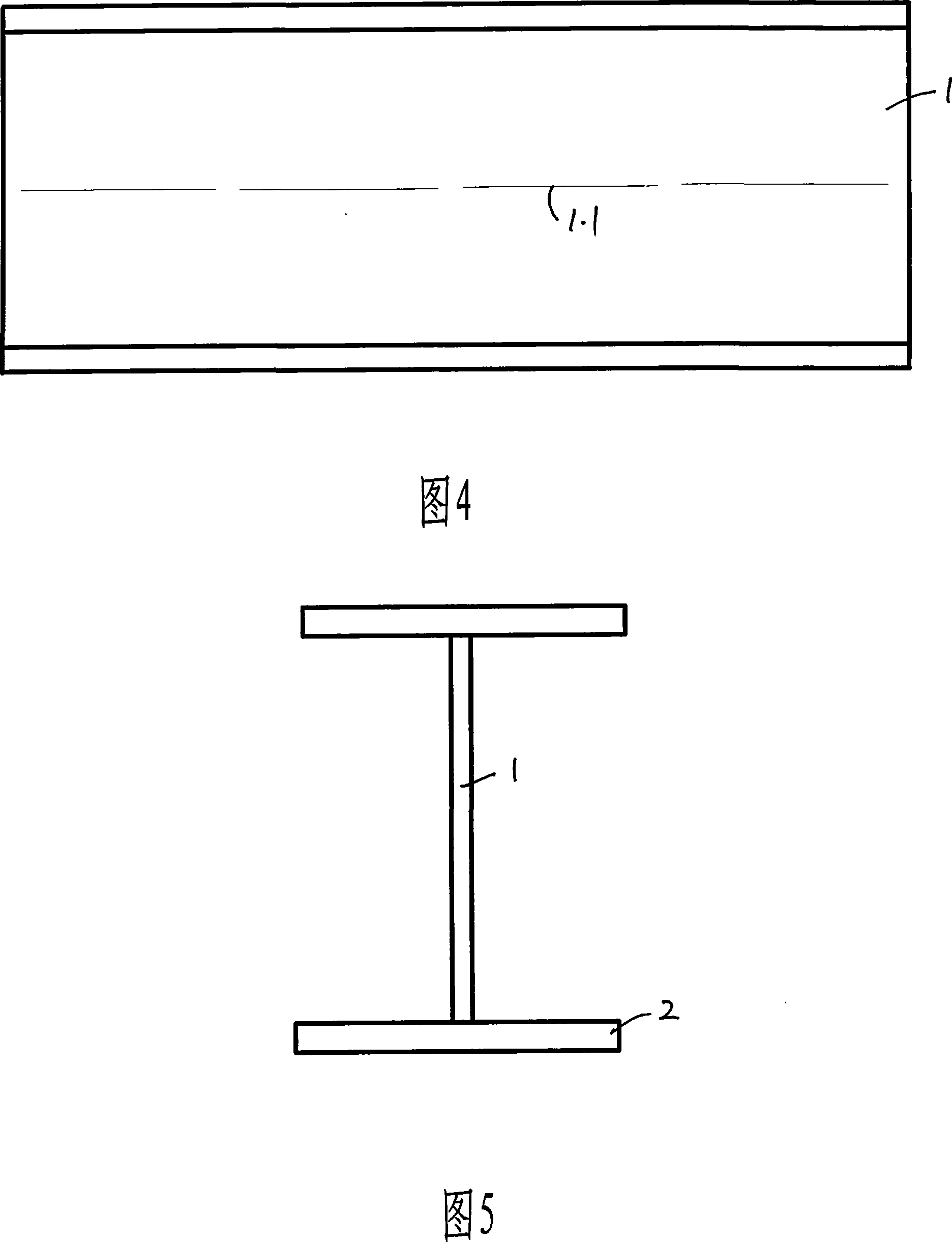

[0013] Embodiment 1: Referring to Figures 4 and 5, each steel plate is cut according to the design requirements, and the H-shaped rods are welded by alternating diagonal cycles, and the center of the web 1 of one H-shaped rod is fixed at a distance of 400mm when cutting. Point solid length 80 ~ 100mm, first flame cut into a point connection shape 1.1, welded into H rods, then cut along this point connection line to form 2 identical T-shaped, and finally put the 2 T-shaped opposite to another H The center of the web plate of the type bar is formed by alternating diagonal circular welding to form a cross column. When welding, use the angle template to check the verticality at any time, adjust the welding sequence and welding amount, and make a slight correction to the specified requirements after welding. hole.

Embodiment 2

[0014] Embodiment 2: If the material does not fit together, the H-shaped web that needs to be cut for welding is cut into two single strips, first straightened and leveled, and the two single strips are spot welded together to form the web 1, and then Weld the two wing plates 2 to make H-shaped rods, then cut them into two T-shaped rods according to the spot welding connection line, and assemble and weld them in the center of the web of the H-shaped rods.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com