Right crank arm assembly for a bicycle and crank arm and front sprocket thereof

A crank arm and front sprocket technology, applied in the field of right crank arm assembly, can solve the problems of front sprocket twist, small thickness, large front sprocket bending, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

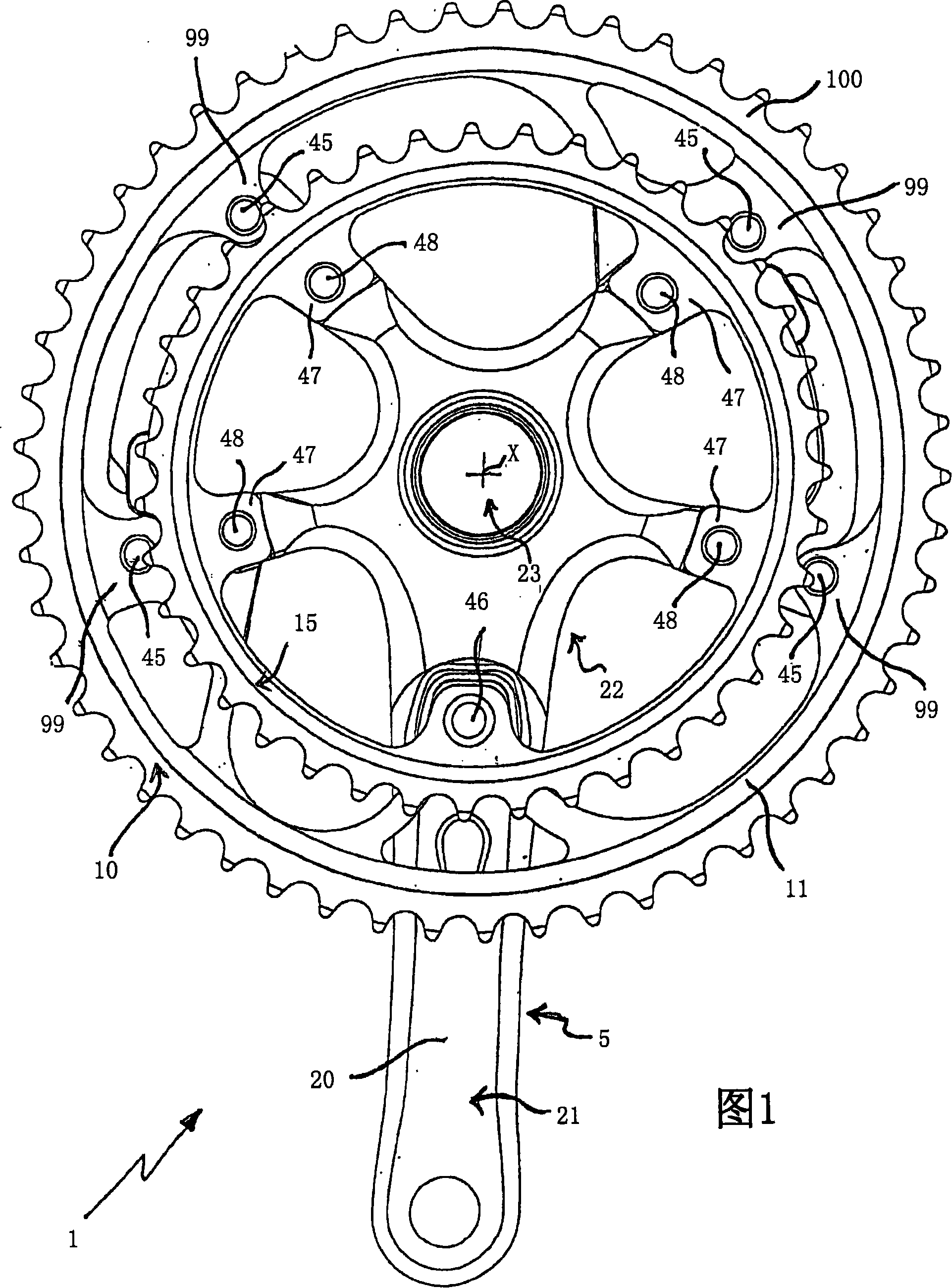

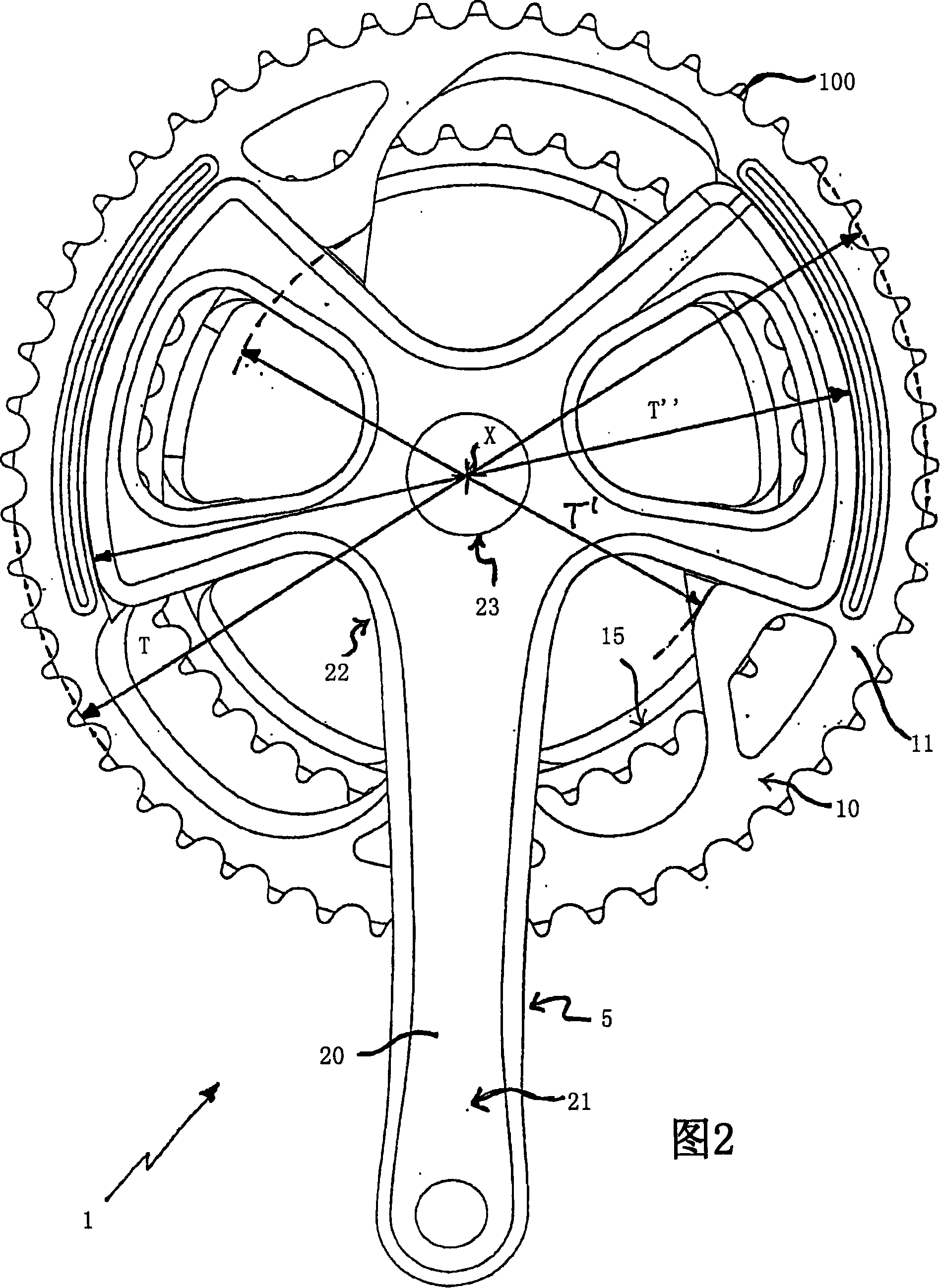

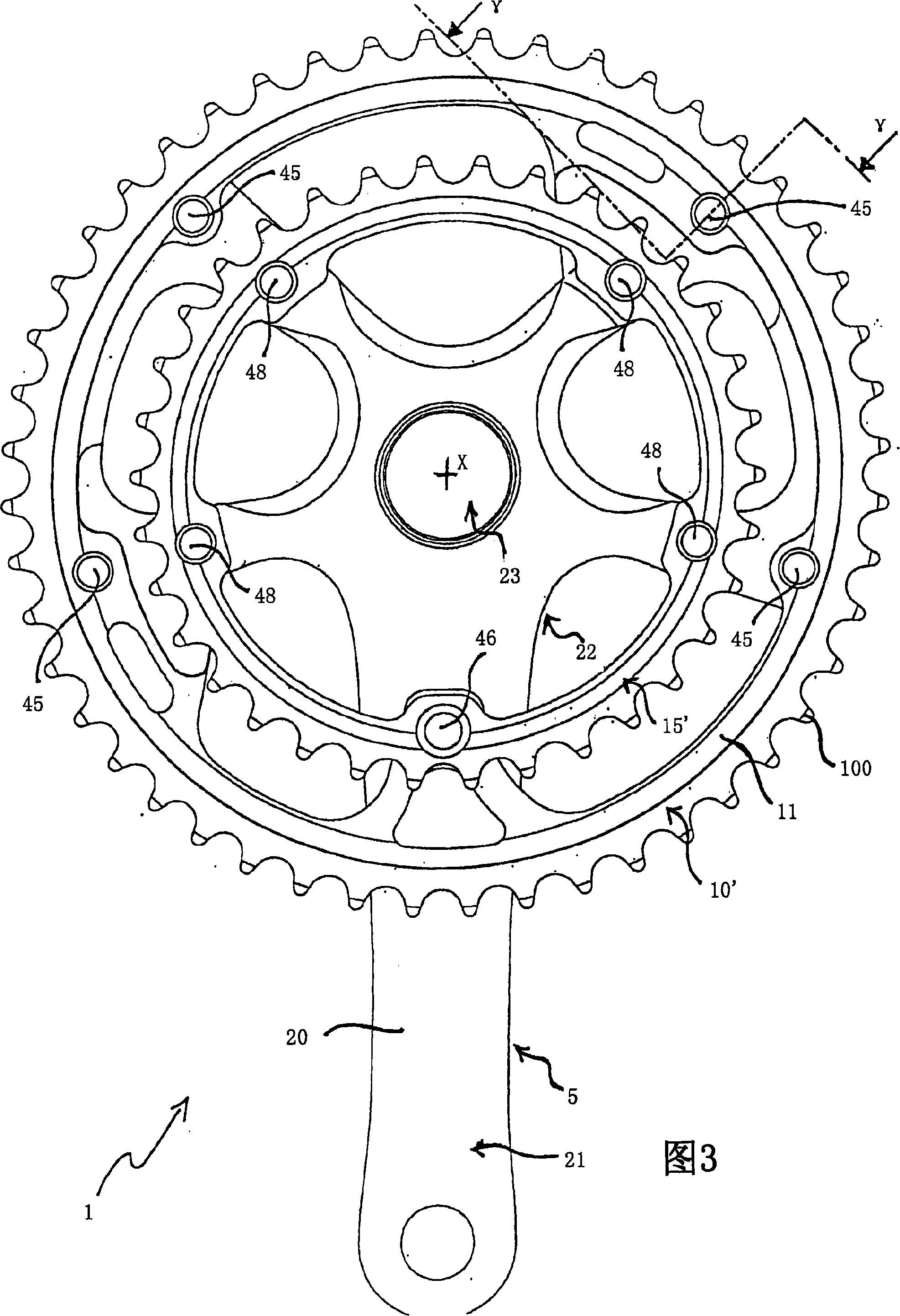

[0140] Referring to FIGS. 1 and 2 , a right crank arm assembly according to the present invention is indicated at 1 . The assembly 1 comprises a right crank arm 5, a large diameter front sprocket 10 (hereinafter referred to as large front sprocket) and a small diameter front sprocket 15 (hereinafter referred to as small front sprocket). Alternative and not shown embodiments are foreseen in which the assembly 1 comprises only one front sprocket, for example for racing use, or more than two front sprockets, for example three front sprockets.

[0141] 8 Throughout the specification and in the claims that follow, "inside" of the assembly 1, of the crank arm 5 and / or of the front sprockets 10 and 15 means the side that can be seen in Figures 1 and 3, i.e. when the assembly 1 The side that faces the bicycle frame when mounted on the bottom frame assembly. On the other hand, "outside" refers to the surface visible in FIGS. 2 and 4 opposite to the inside.

[0142] Moreover, througho...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com