Method for harnessing chemical production thiamine crystallization tank region local geological foundation pollution

A technology of chemical production and crystallization tanks, applied in chemical instruments and methods, restoration of polluted soil, organic fertilizers, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

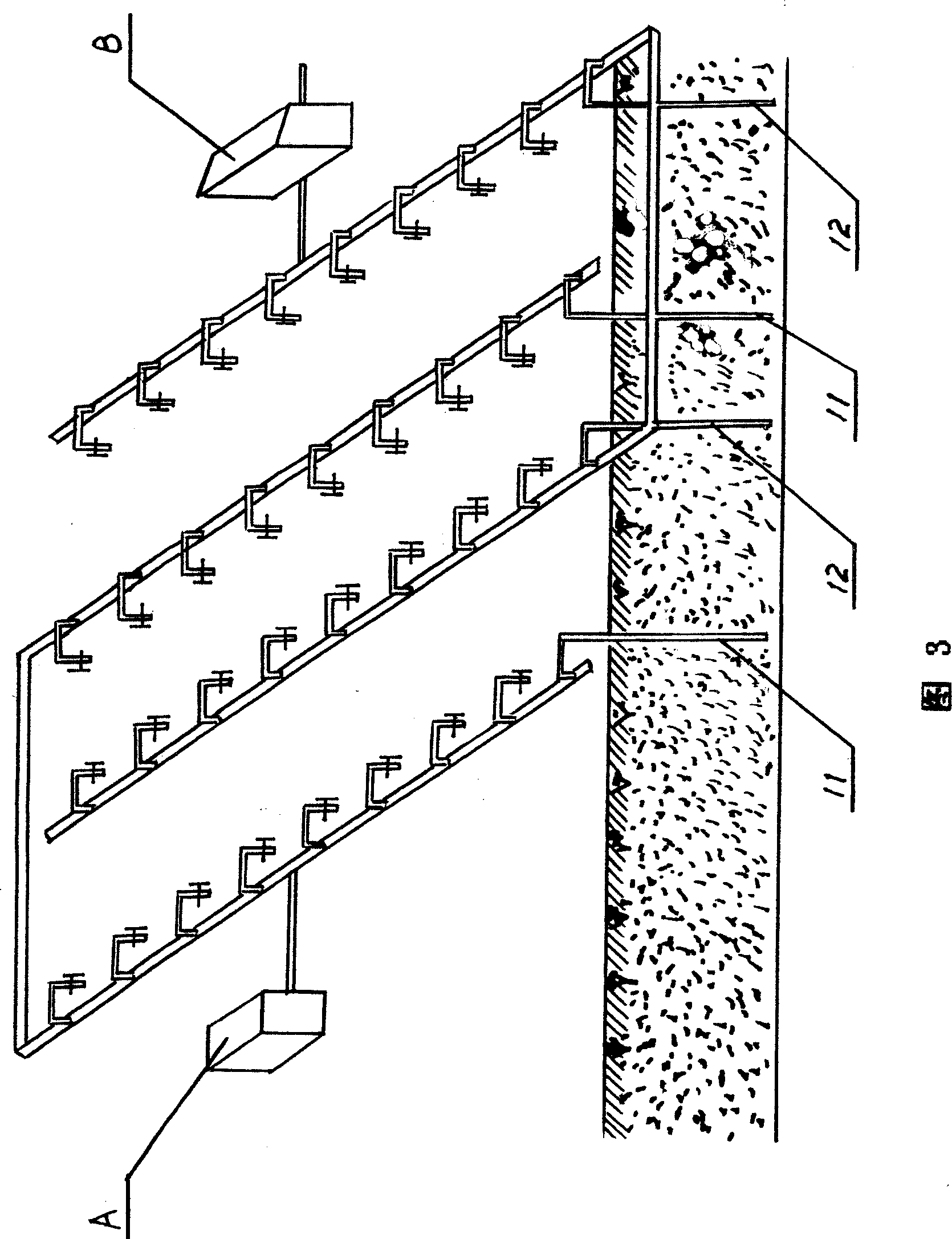

[0018] This method for the control of local geological foundation pollution in chemical industry production thiamine crystallization tank area proposed by the inventor, it is realized by the following steps:

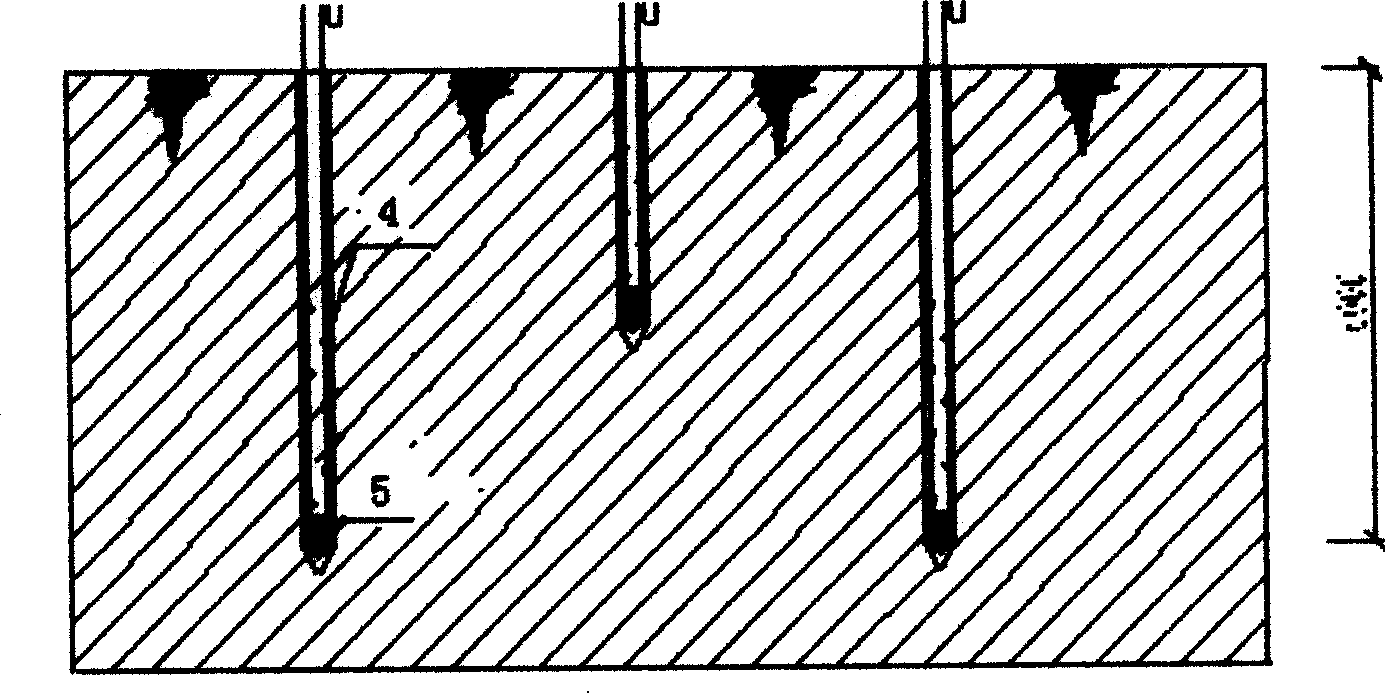

[0019] A. Confirm the scope of treatment, excavate deep trenches on its outer edge, and build a separation wall with a depth slightly greater than the depth affected by acidification;

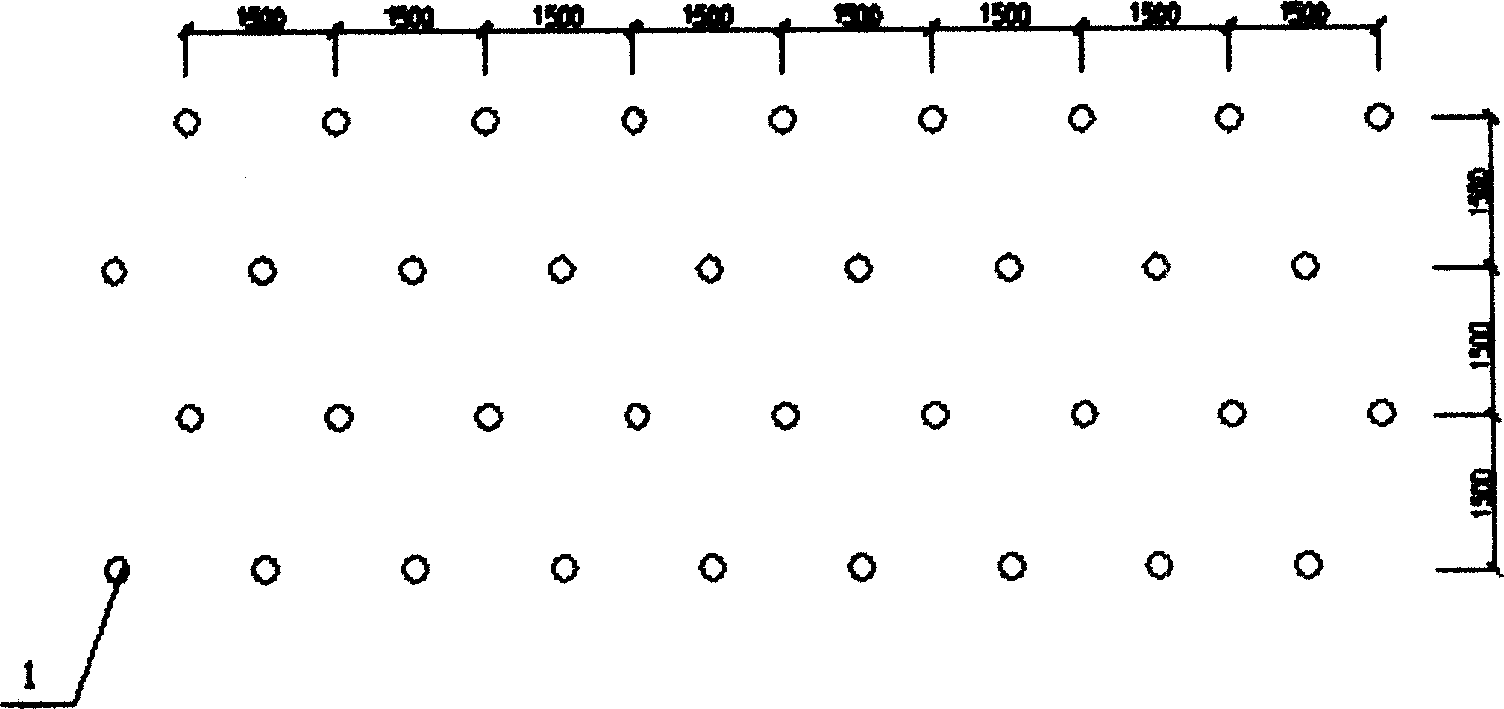

[0020] B. Arrange quincunx-shaped boreholes with a hole spacing of not less than 1.5m in the above-mentioned enclosed spacer area, and arrange the hole array into a regular combination of grouting well pipes in one row and pumping well pipes in the other row type well array; and every four rows of holes are used as the operation unit for grouting and drainage;

[0021] C. Inject Ba(OH) into the grouting well 2 The main treatment liquid, as well as polymer flocculants and water treatment accelerators, form BaSO in the soil with acid and alkali resistance, high specific gravity, absorption...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com