A method for changing a reel in a reeling process of a fiber material web and a reel change apparatus

A technology of fiber materials and equipment, which is used in the field of roll changing and roll changing equipment in the coiling process of fiber material webs, and can solve problems such as paper web breakage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

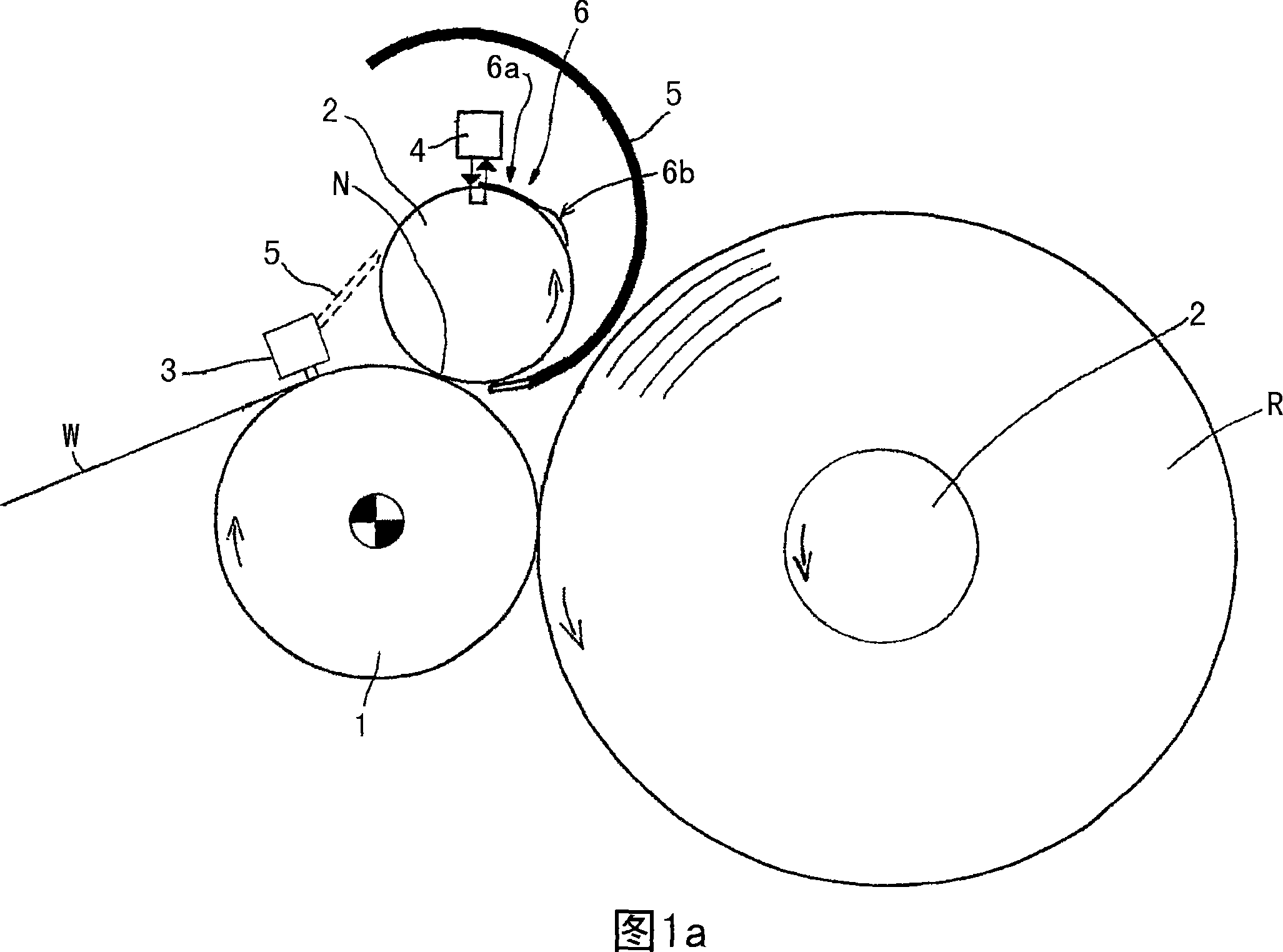

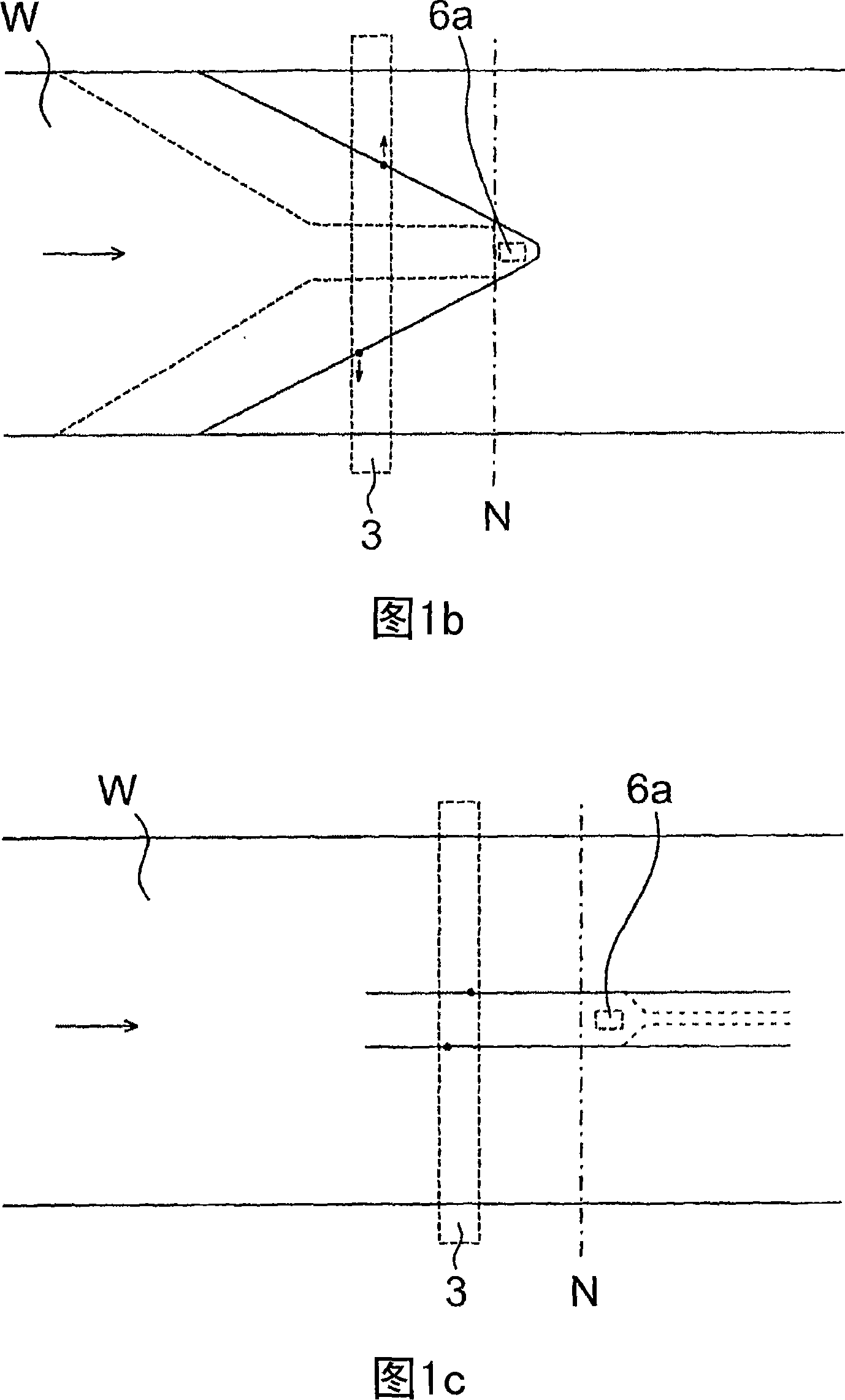

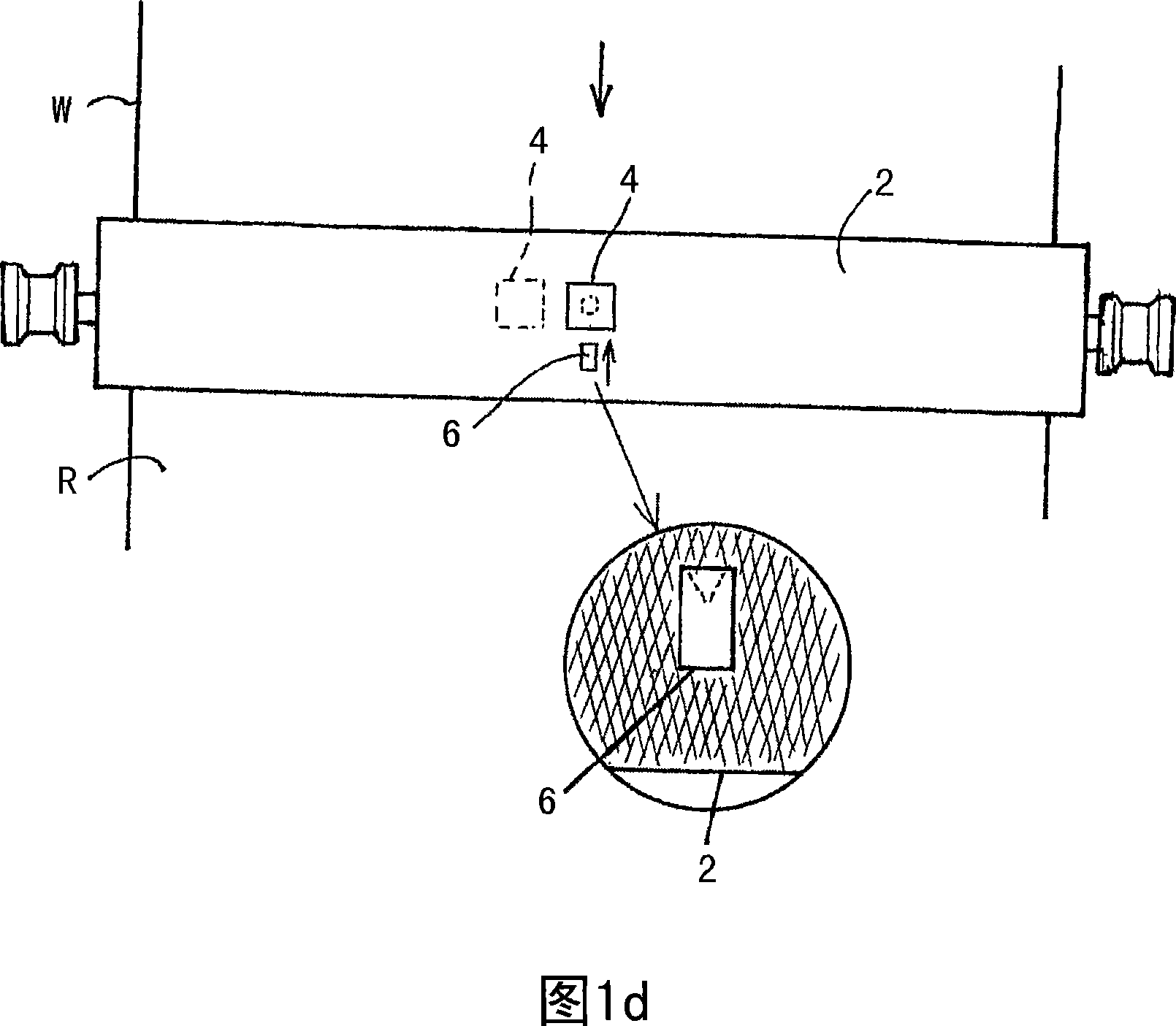

[0035] In the state of FIG. 1 a, a new reel serving as a new core 2 is in the roll change position, and a web of fibrous material W, such as a paper web, running to an old, already full roll, is in this position. connected, so this connection makes replacement possible. The winding core 2 contacts the web running on the surface of the web guide (coiling cylinder 1 ) in such a way that the winding core forms a changing nip N with the web guide and essentially in the same manner as the paper The running speed of the web rotates at the corresponding peripheral speed. After the change nip N between the winding core 2 and the take-up cylinder 1, the web moves on the surface of the web guide to the actual take-up nip, through which the web is wound on On a paper roll that gradually fills up. Hereinafter, the nip N refers to the nip formed in the replacement position, that is, the replacement nip.

[0036]The roll changing device shown in Fig. 1a comprises: cutting device 3, which...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com