Vacuum valve

A technology of vacuum valve and vacuum zone, applied in sliding valve, valve details, valve device and other directions, can solve the problems of complex structure, large structure, high cost, etc., and achieve the effect of high torsional rigidity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

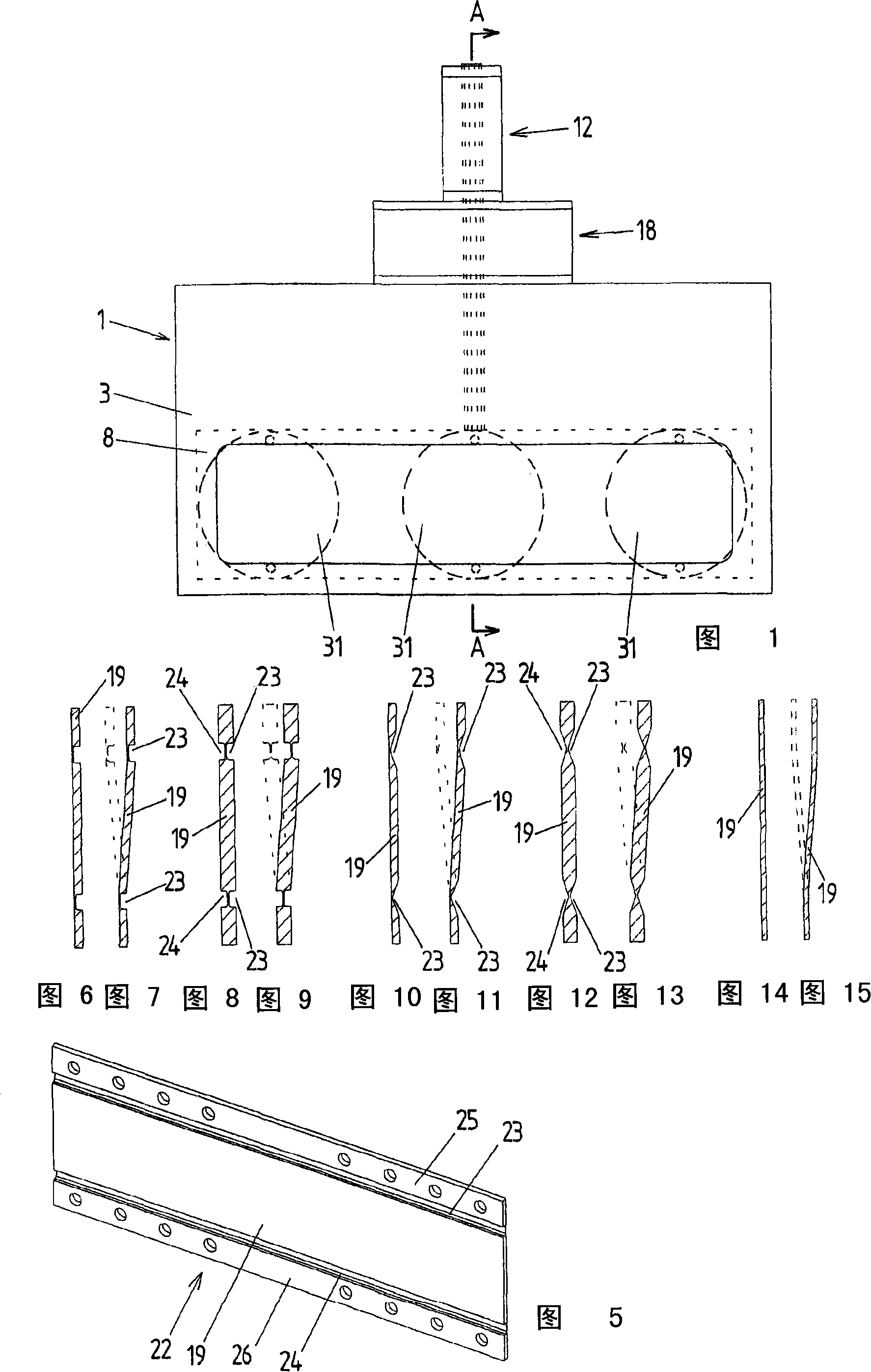

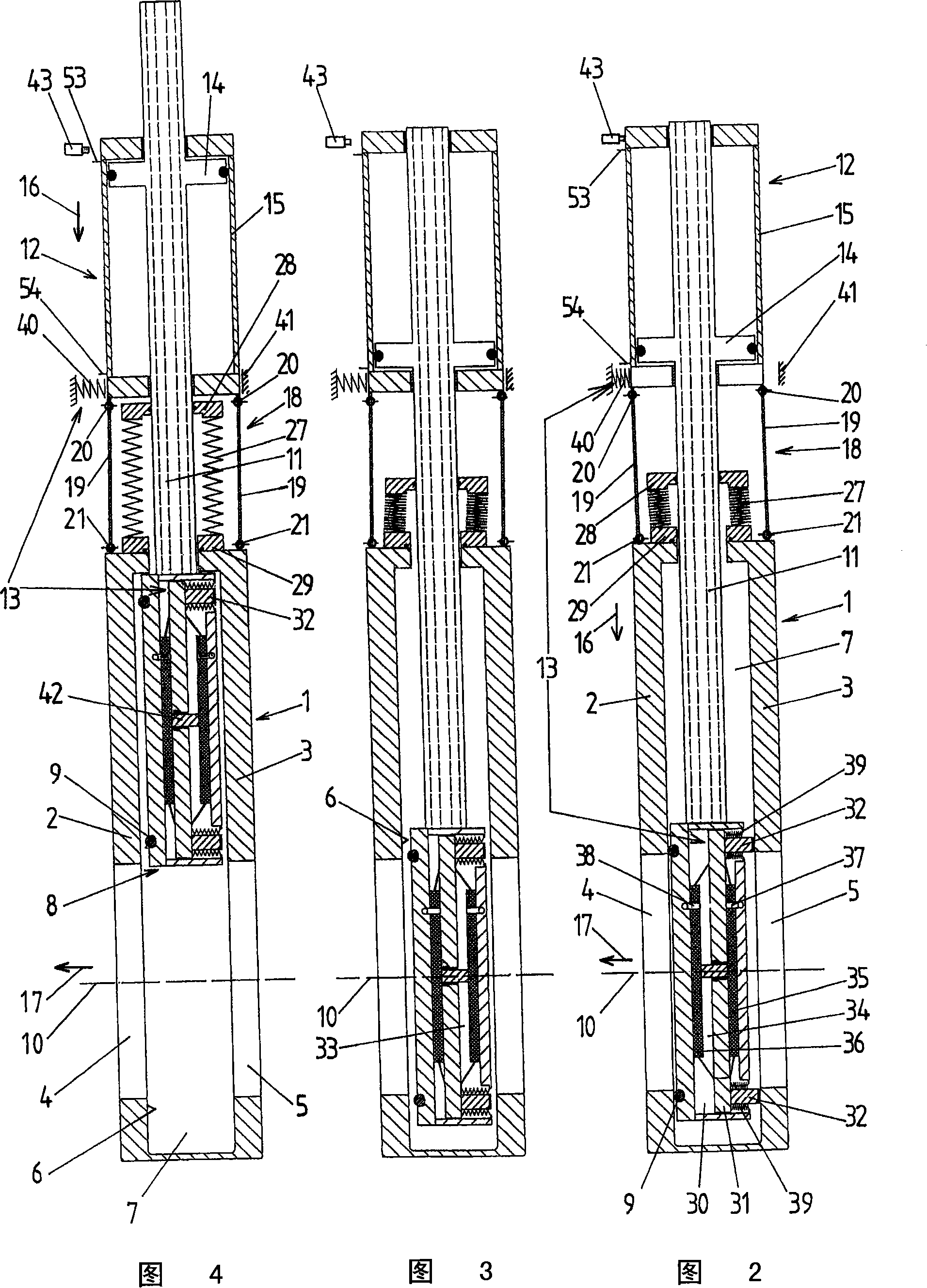

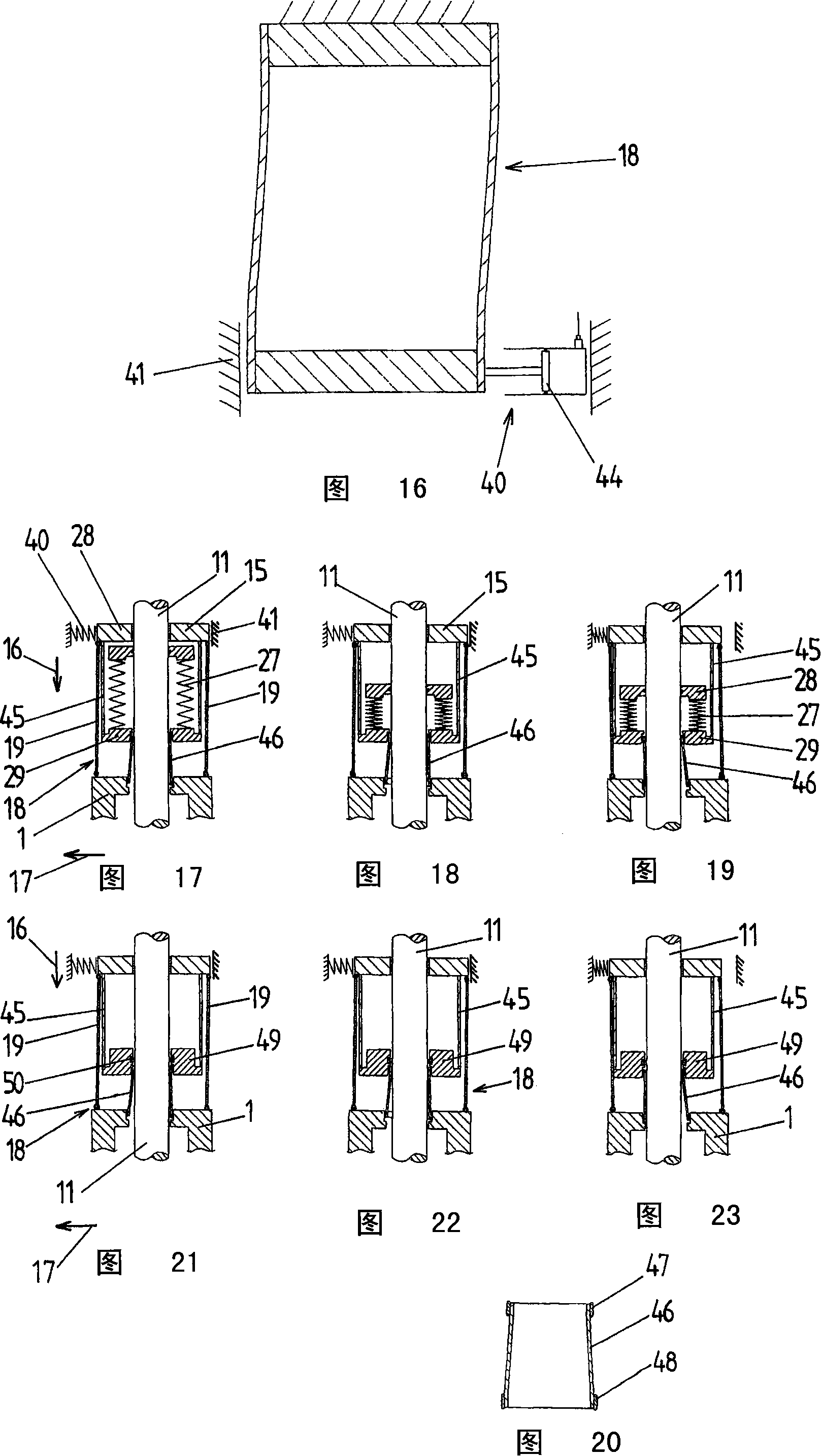

[0034] A first exemplary embodiment of the invention is schematically shown in FIGS. 1 to 7 . The vacuum valve has a valve body 1 which, in the exemplary embodiment shown, is designed as a housing. The opposing walls 2 , 3 are pierced by an inlet opening forming a valve opening 4 and an outlet opening 5 . The valve opening 4 is surrounded by a valve seat 6 formed by a sealing surface on the inner side of the wall 2 .

[0035] In the exemplary embodiment shown, the longitudinal axis 10 of the valve opening coincides with the longitudinal axis of the outlet opening 5 , as is preferred.

[0036] The inner space 7 of the valve body 1 forms the vacuum region of the vacuum valve, in which inner space 7 a valve plate 8 is arranged. In the closed position of the valve plate 8 , it is pressed against the valve seat 6 , wherein the seal 9 of the valve plate bears against the valve seat 6 .

[0037] For example, the seal 9 can also be arranged on the valve seat 6 and a sealing surface...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com