Break detecting device of sewing machine needle

A detection device and sewing machine needle technology, applied in the direction of sewing machine control devices, sewing machine components, sewing equipment, etc., can solve the problems of difficult needle breaking judgment, mutual interference, serious bending degree, etc., and achieve the effect of simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

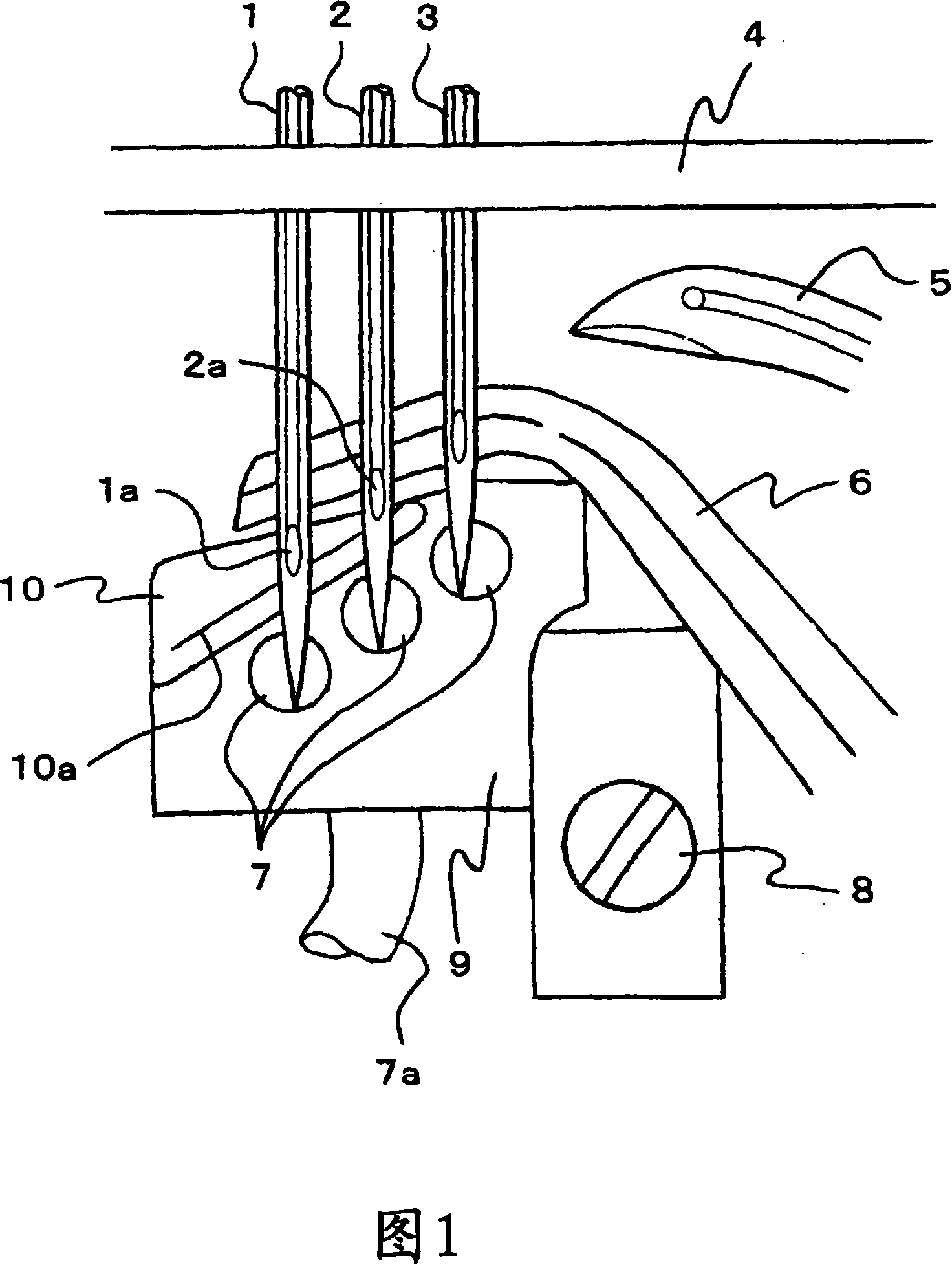

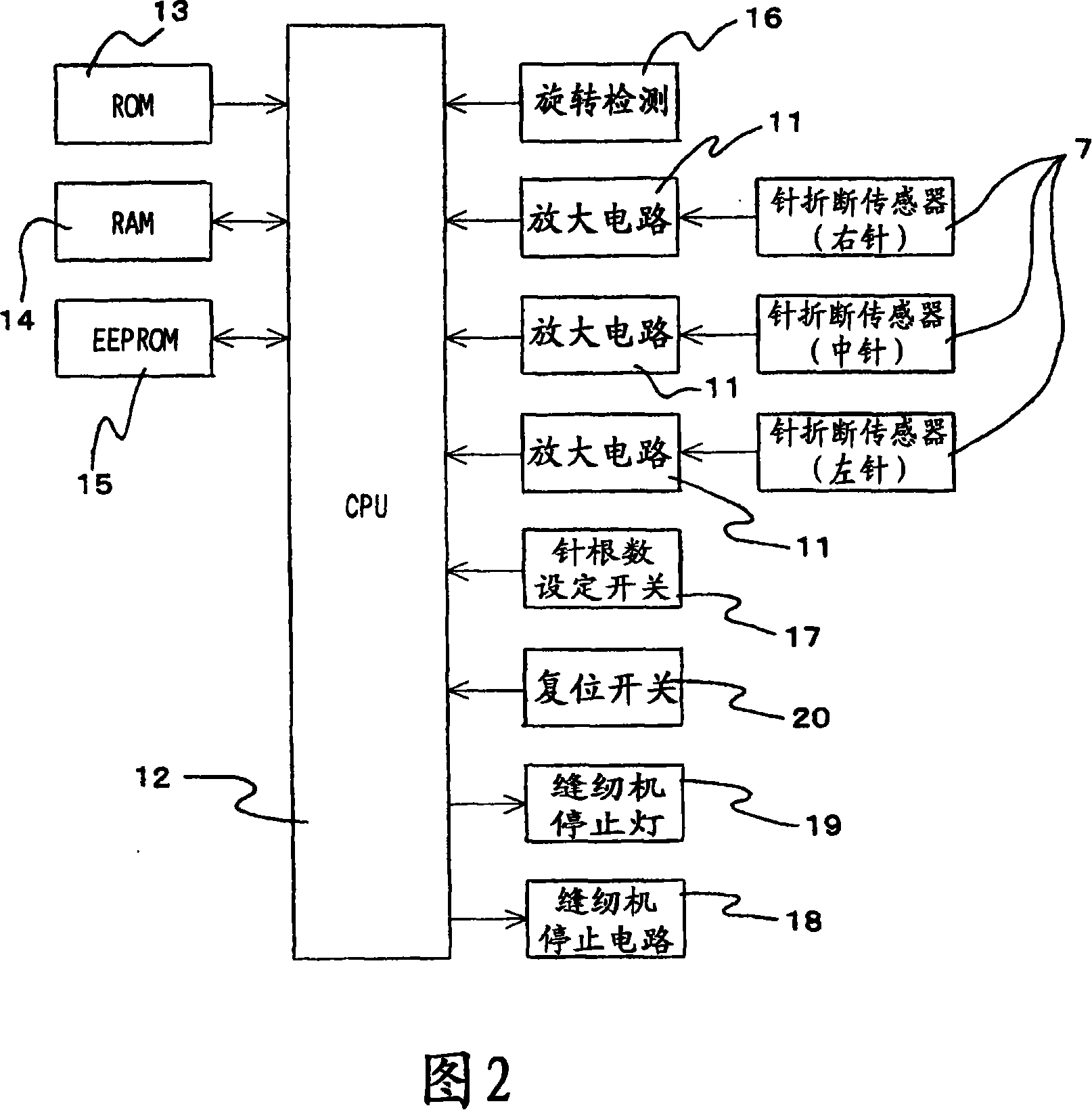

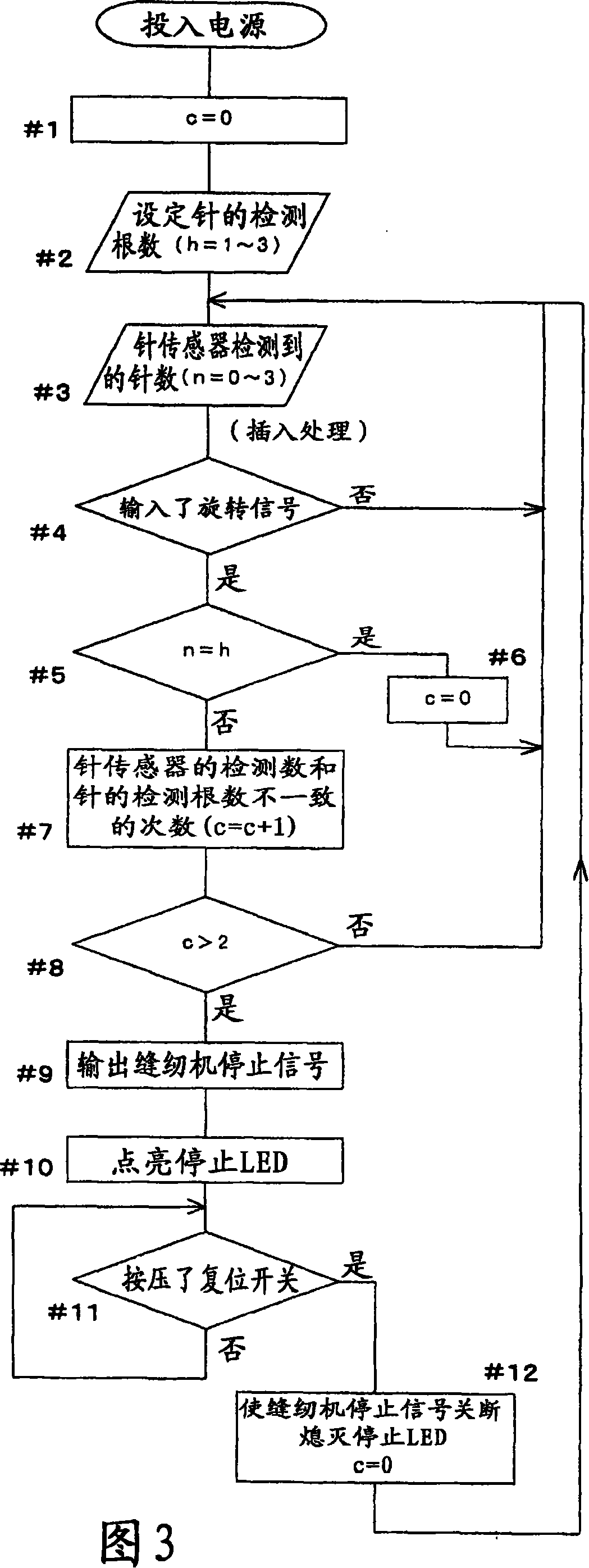

[0012] Embodiments of the present invention will be described below based on the drawings. Three needles arranged side by side (left needle 1, middle needle 2, and right needle 3) reciprocate up and down in conjunction with the rotation of the main shaft, and their front ends pass through the needle plate 4 when descending. Below the needle plate 4, the looper 5 swings left and right in conjunction with the rotation of the main shaft. As shown in FIG. In addition, a needle guard 6 is disposed behind each needle that reaches the bottom dead center. The needle guard 6 is configured to be connected to a known forward and backward movement mechanism, and advances to approach the rear of the needle when the needle starts to rise.

[0013] Below the needle plate 4, a proximity sensor 7 for detecting the presence or absence of a needle is provided. This time, in order to apply it to a three-needle sewing machine, three proximity sensors are arranged side by side on the left and rig...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com