Technique for manufacturing tetrabromoethane and equipment thereof

A tetrabromoethane and process technology, applied in the field of preparation of tetrabromoethane, can solve the problems of explosive tetrabromoethane yield and low quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

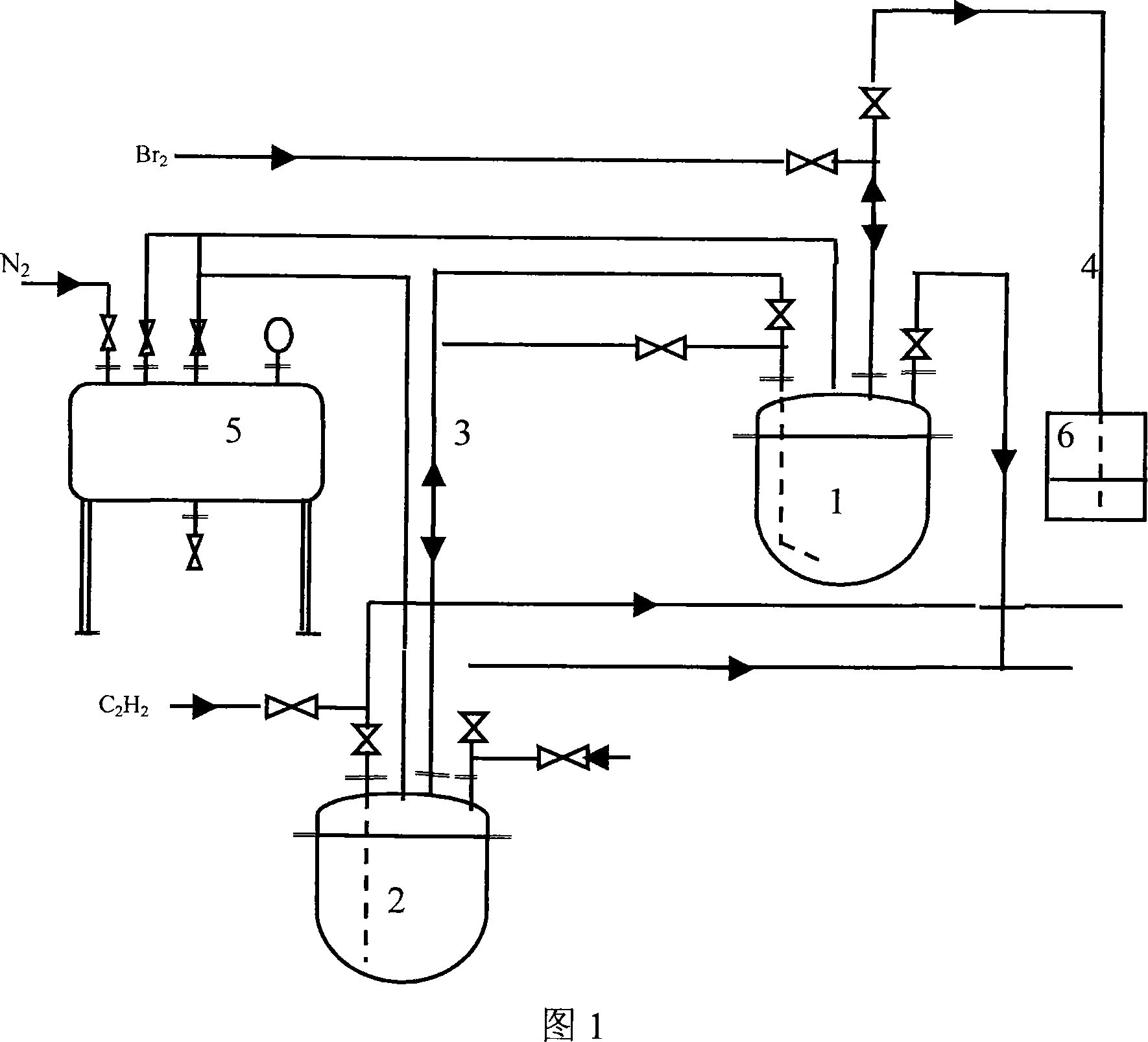

[0011] In Fig. 1, the tail gas kettle 1 communicates with the bromine source, the synthesis kettle 2 communicates with the acetylene, the connecting pipe 3 communicates the tail gas kettle and the synthesis kettle, and the tail gas discharge pipe 4 communicates the tail gas kettle and the alkaline water absorption barrel 6. The nitrogen balance tank 5 communicates with the tail gas kettle, the synthesis kettle and the nitrogen source respectively.

[0012] The process for preparing tetrabromoethane is described below. The bromine liquid in the bromine source (raw material tank) is sucked into the tail gas kettle 1 through vacuum suction, and then sucked into the synthesis kettle 2 through the connecting pipe 3. After venting to eliminate the vacuum, feed the synthesis kettle with the nitrogen in the nitrogen balance tank 5, and the air (comprising a small amount of bromine) in the synthesis kettle enters the tail gas kettle 1 through the connecting pipe 3; feed the tail gas wit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com