Secure power supply jack with ratchet wheel clamping machine

A technology of clamping mechanism and safety power supply, applied in the direction of circuits, electrical components, parts of connecting devices, etc., can solve the problems of electric danger, non-compliance with double-sided contact, affecting the effect of use, that is, lifespan, etc., and achieves easy operation habits. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment

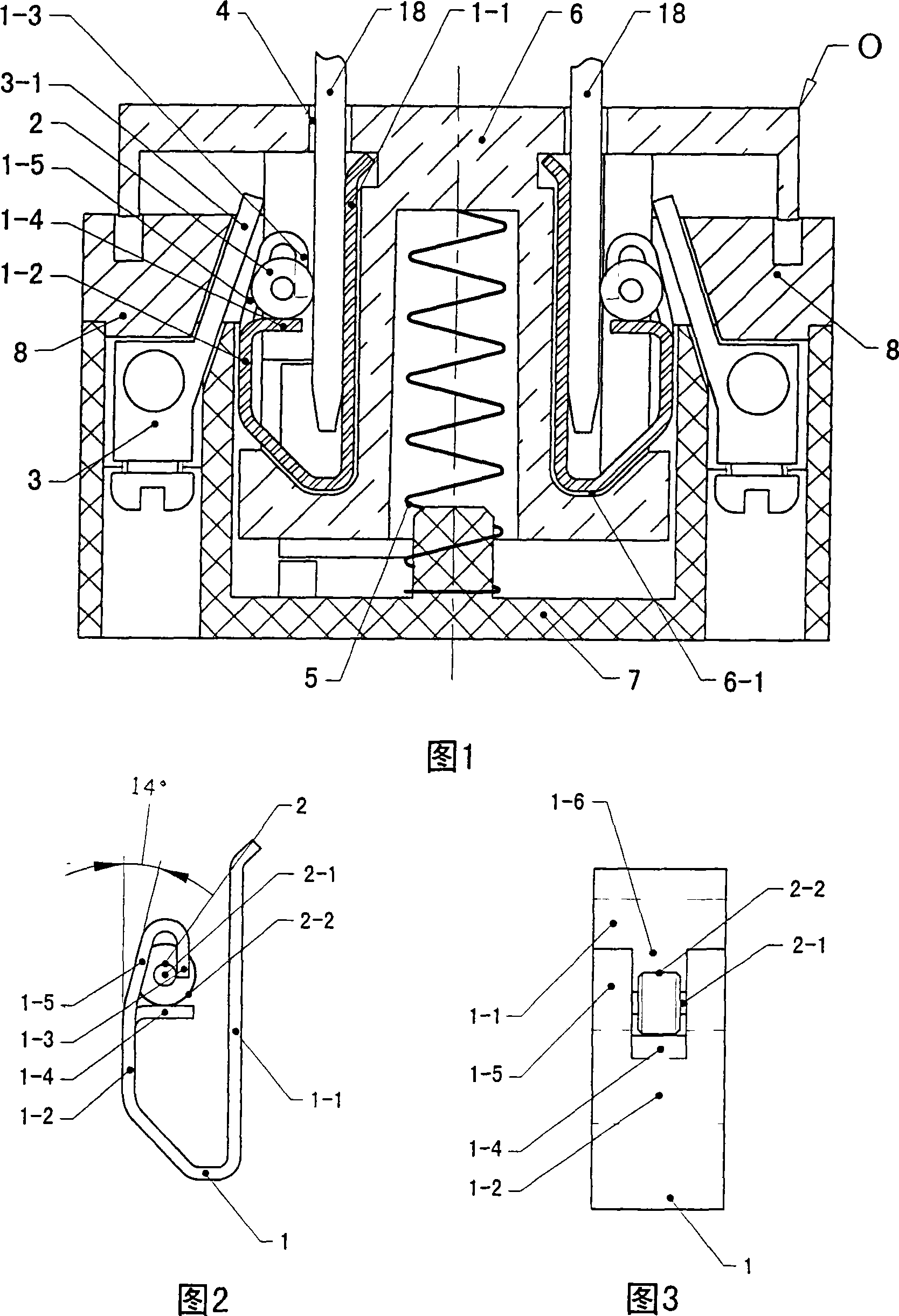

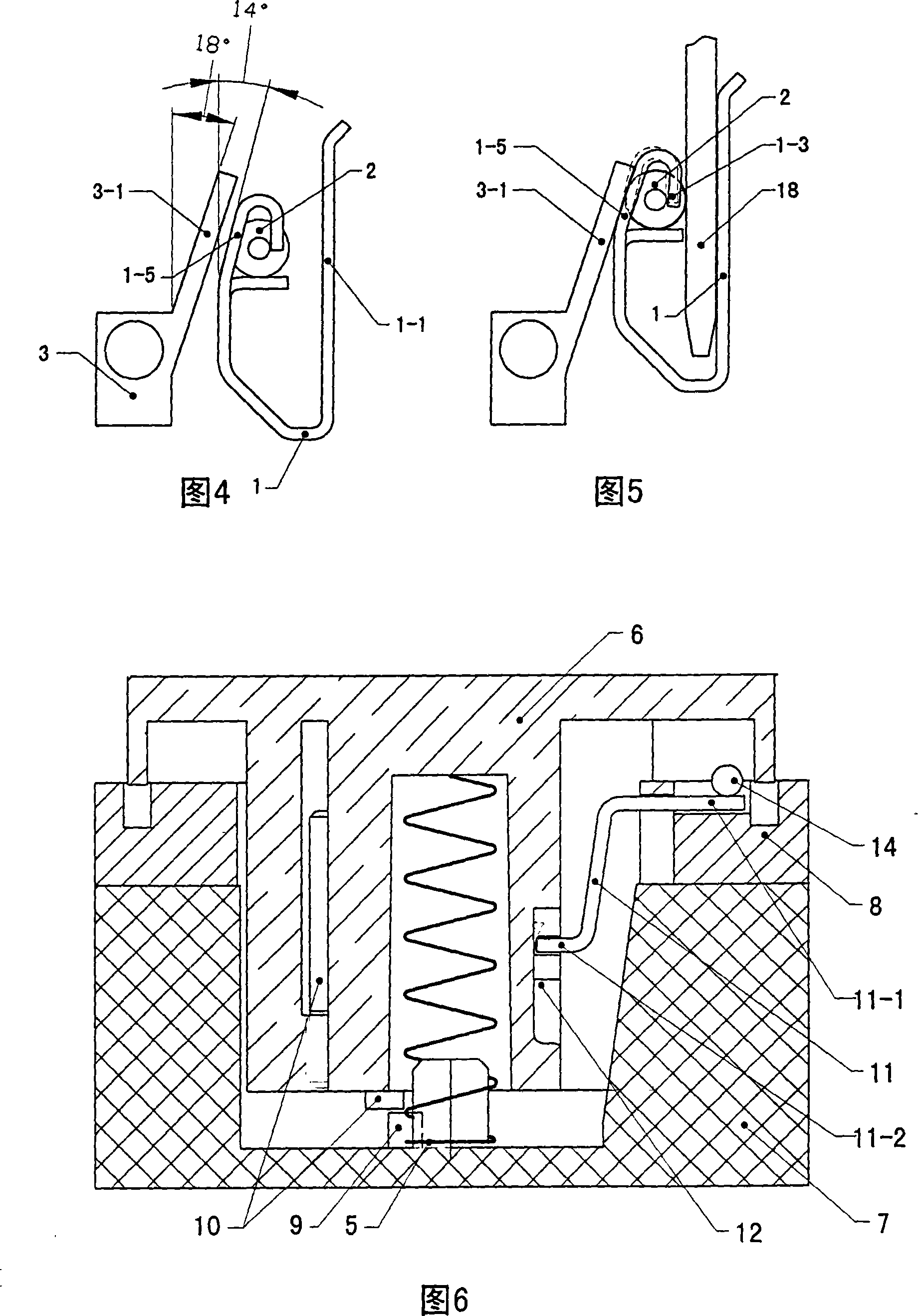

[0023] Fig. 1 is a cross-sectional view of the structure of the present invention, Fig. 2 is a schematic structural view of a conductive clip with a ratchet clamping mechanism, Fig. 3 is a right view of a conductive clip with a ratchet clamping mechanism: the present invention includes a seat shell 7, a shell cover 8, a hollow core Body 6, the support spring 5 between the hollow core body 6 and the seat shell 7, the power terminal 3, the jack 4 and the conductive contact piece in the jack, the conductive contact piece is the conductive clip 1 of the ratchet clamping mechanism, the conductive clip It is ear-shaped, and the conductive sheet 3-1 of the power terminal is inclined at an angle inside the shell cover. The upper part of the conductive sheet is fixed by the shell cover 8 so that the angle does not change. The conductive clip is placed between the inclined conductive sheet 3-1 and the hollow core. 6 forms a right-angled trapezoidal space, embedded in the groove 6-1 of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com