Movable contact of circuit breaker

A circuit breaker and moving contact technology, applied in the direction of circuit breaker contacts, circuit breaker components, contacts, etc., can solve the problems that have not been reported in the literature successfully, and achieve the improvement of short-term withstand current value and overall Effective volume control to ensure the effect of miniaturization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

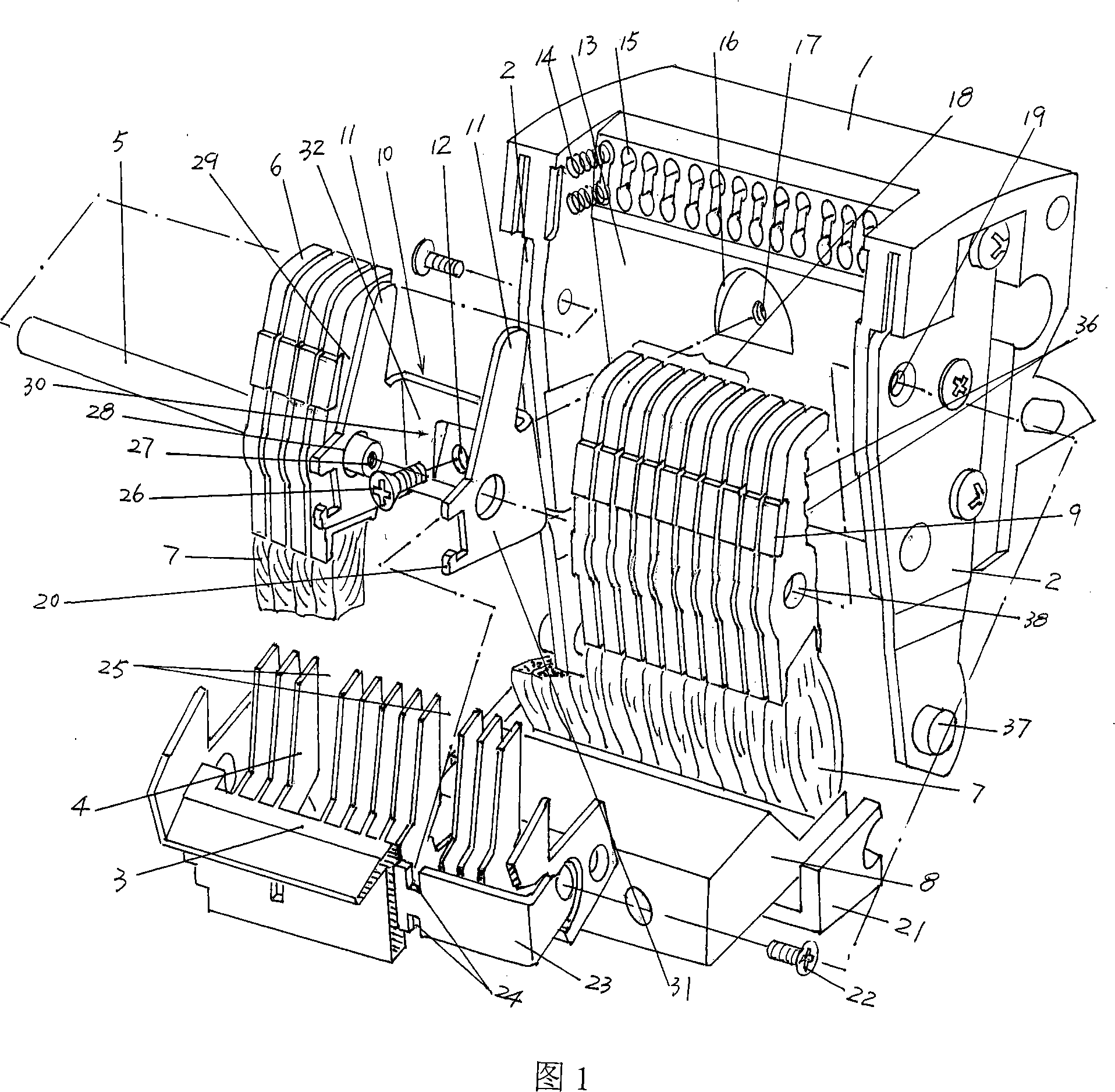

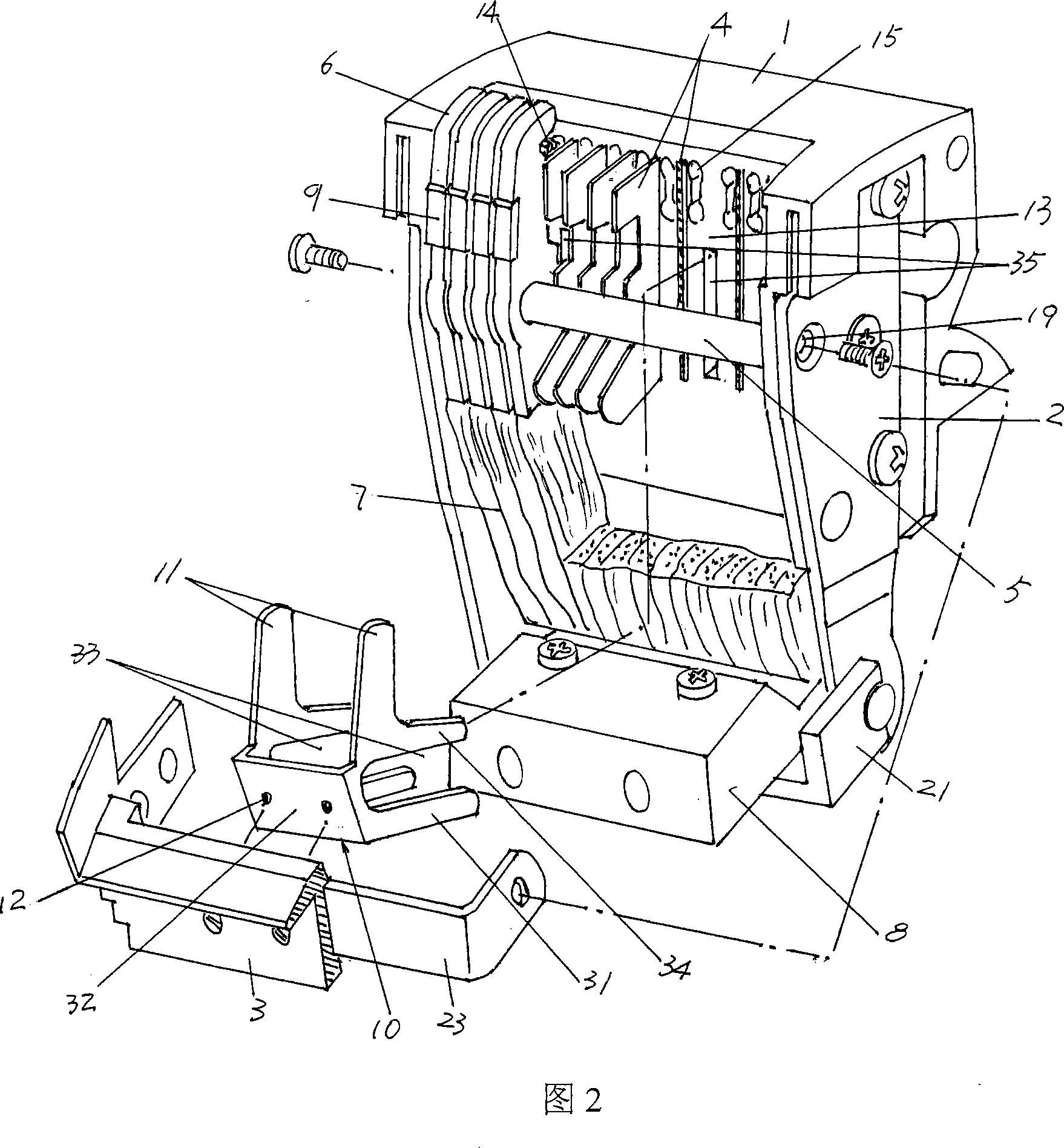

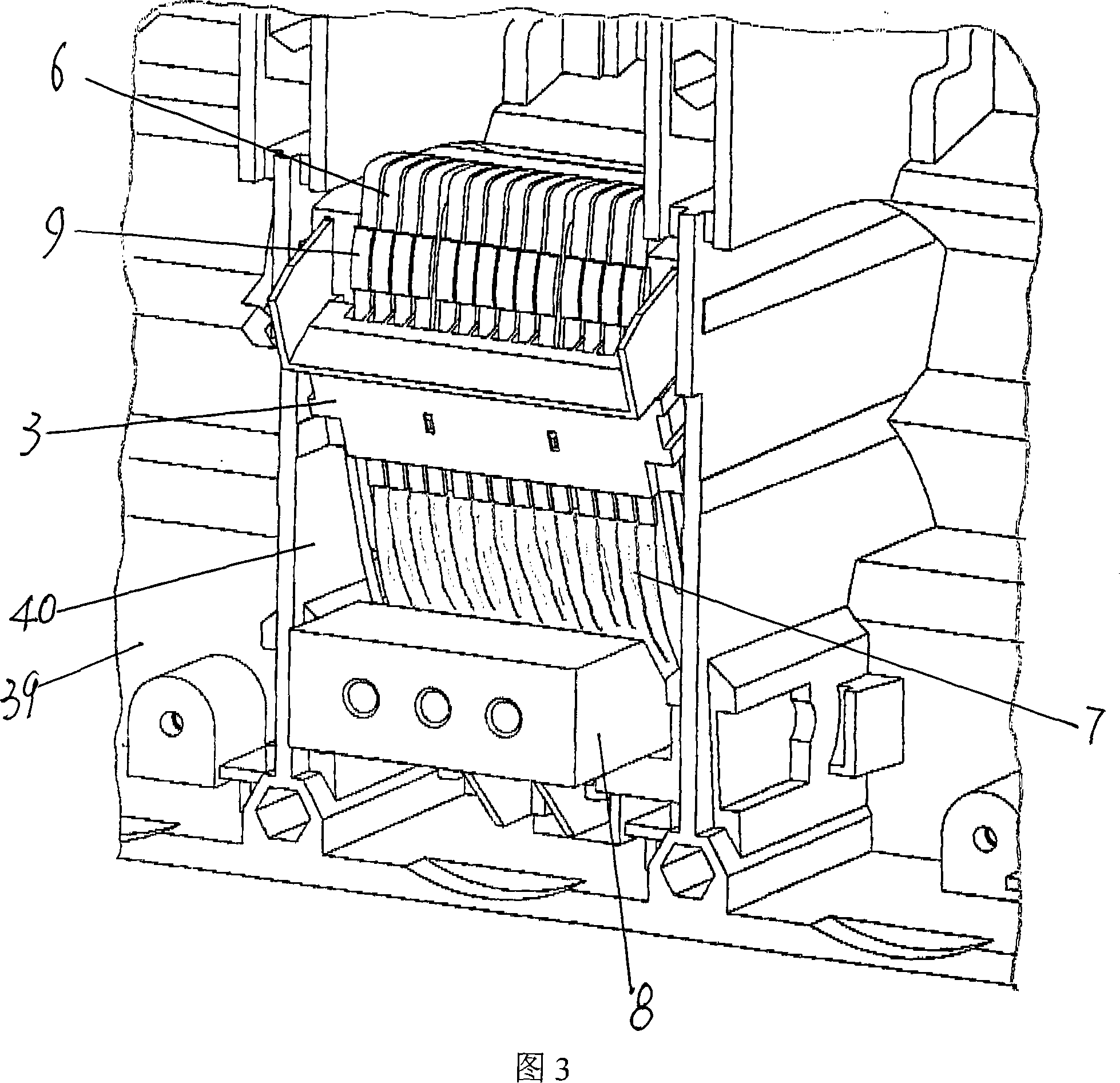

[0023] Please refer to Fig. 1 in detail, which provides an insulating support 1 whose material is preferably plastic. The side of the insulating support 1 facing a group of parallel conductors 6 is processed into an insulating slope 13, and the upper area of the insulating slope 13 is arranged with a set of The number of conductors of the parallel conductor 6 is equivalent to the spring hole 15 corresponding to the position. The spring hole 15 can also be called a spring seat. One end of the spring 14 is inserted in each spring hole 15, and the other end of the spring 14 is resisted on the parallel conductor 6. The upper spring is accommodated on the concave cavity 36 . In the middle part of the insulating support 1, more specifically, in the middle part of the upper part of the insulating slope 13, a concave cavity 16 for fixing the fixing bracket 10, which will be described in detail below, is processed, and the central processing of the concave cavity 16 There are threade...

Embodiment 2

[0028] Please refer to FIG. 2 . As another specific embodiment, a set of grid pieces 4 is extended on the insulating slope 13 of the insulating support 1 . On a pair of side walls 31 of the parallel conductor connection cavity 30 of the fixed bracket 10, slots 33 corresponding to each other are provided respectively. It can be accompanied by the parallel conductor 6 without causing the rotary support shaft 5 to pass through the pair of fixed plates 2 to form an obstacle, so the slot 33 spans the rotary support shaft 5 . The second pins 34 narrowly extend in the direction of the pair of side walls 31 facing the insulating support 1. In order to compensate for the pair of second pins 34, a pair of second pin receiving grooves are opened on the insulating slope 13 of the insulating support 1. 35. The bottom wall of the parallel conductor receiving cavity 30 is fixed to the grid seat 3 by screws or other similar means, so as to ensure that a pair of side walls 31 of the fixing br...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com