Electrical relay

A relay, bottom plane technology, applied in the direction of electromagnetic relays, relays, electromagnetic relay details, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

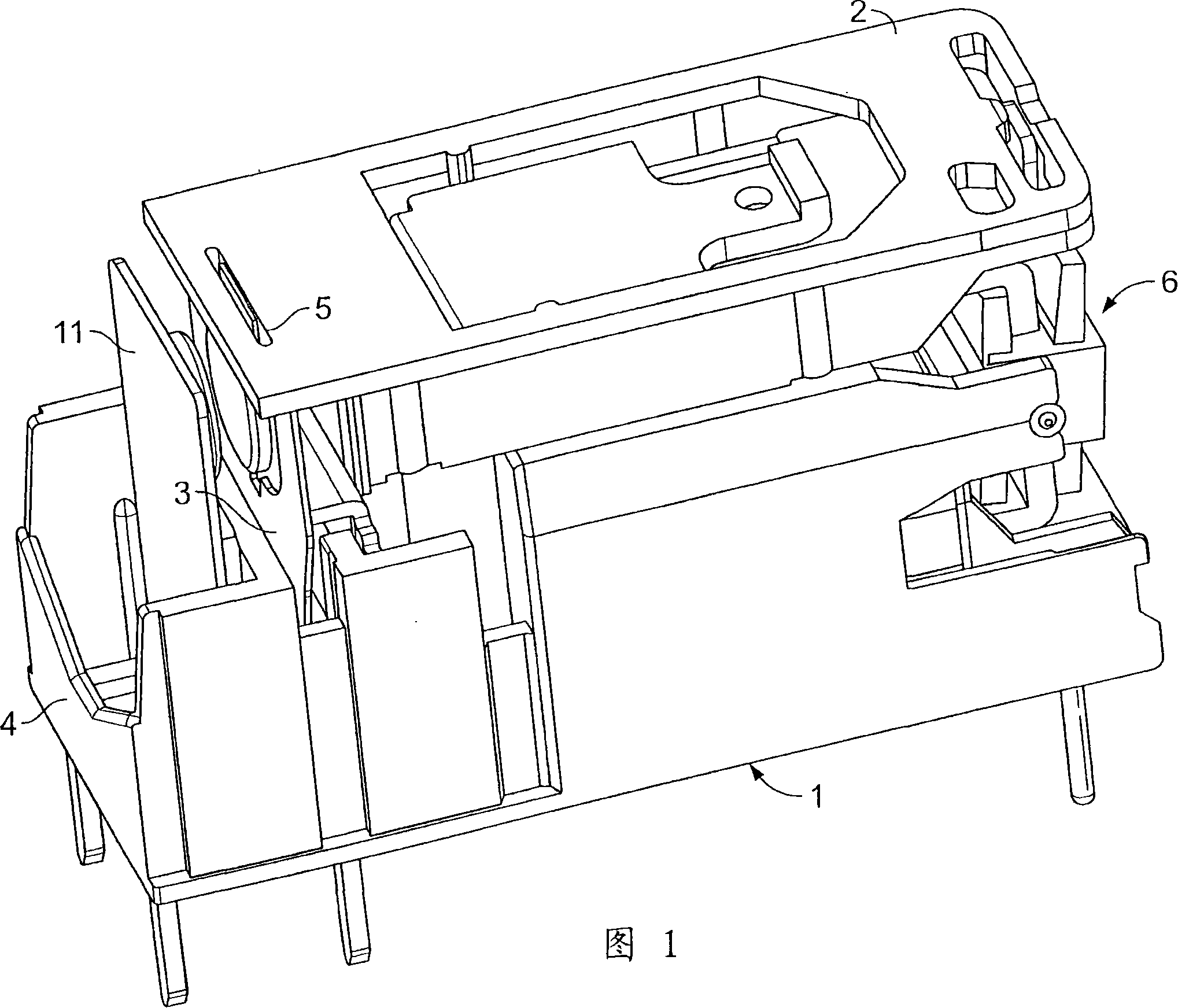

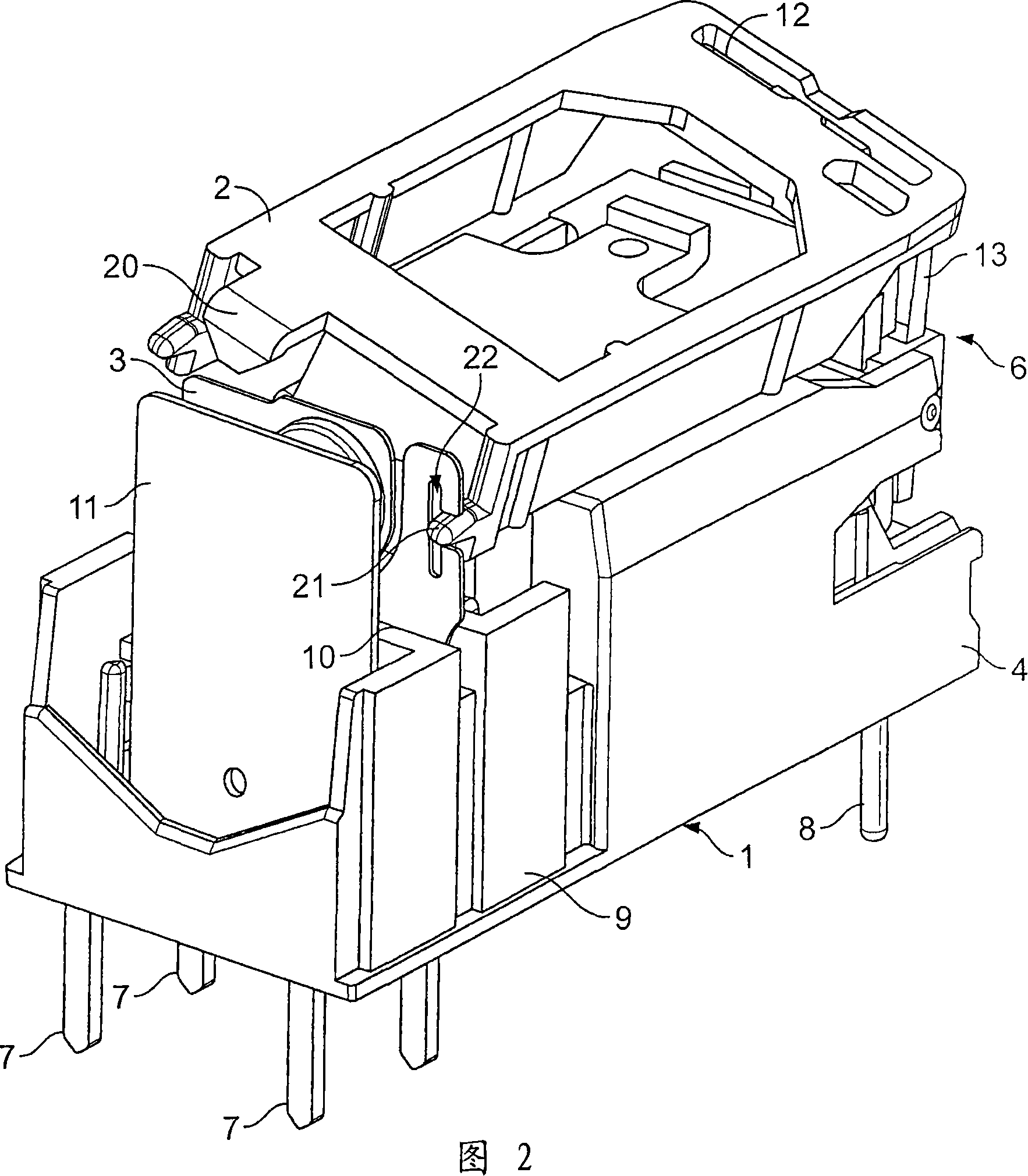

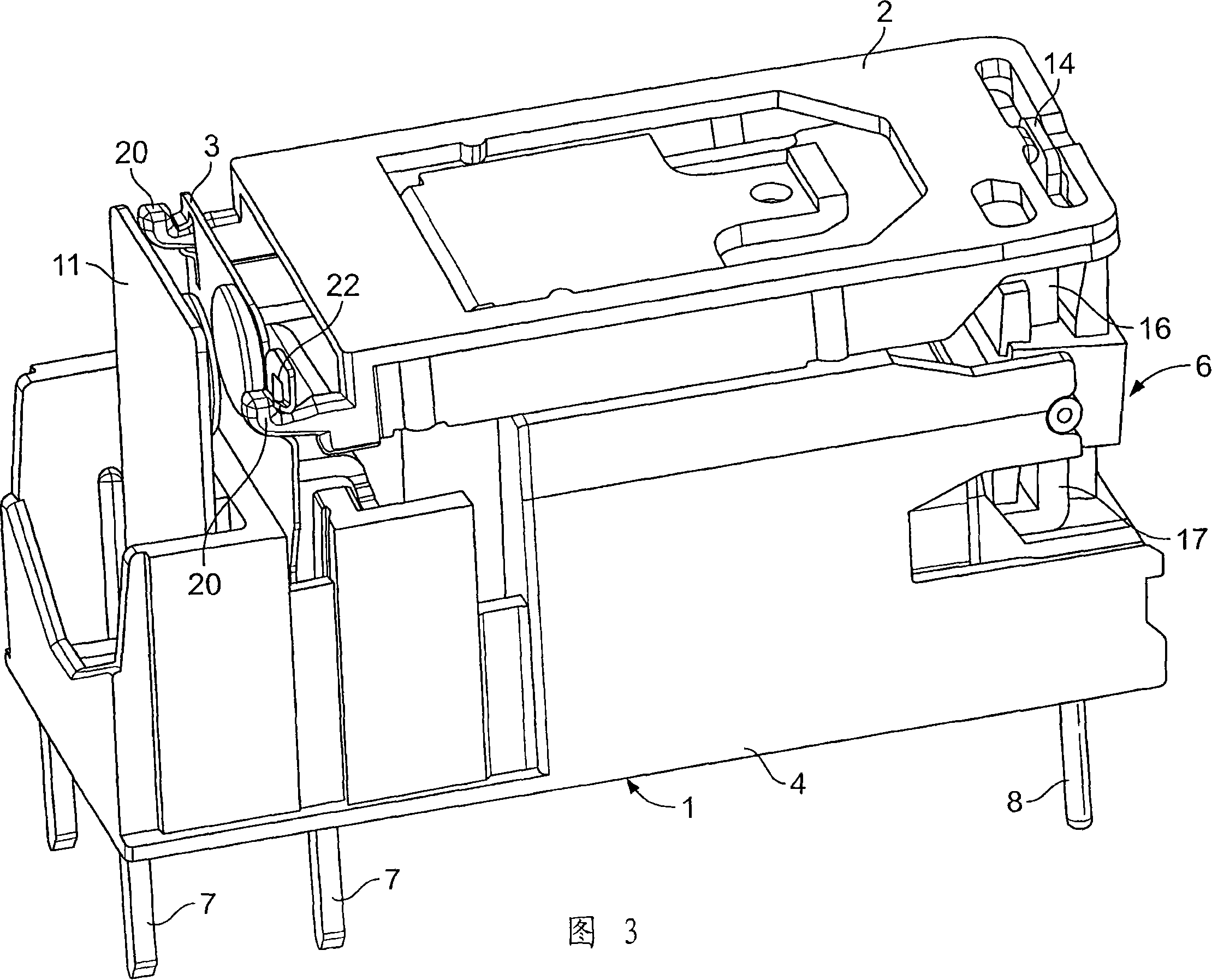

[0023] FIG. 2 shows a first embodiment of a bistable relay according to the invention with an H-shaped armature 6 . The relay shown in FIG. 2 has a base part 4 made of insulating material, extending straight towards the connection side; and a bottom side defining a bottom plane 1 from which electrical terminals 7 and 8 protrude. The base part 4 has a flat, through-bore slot for receiving the magnetic system, however, for example, the remainder comprising the raised side walls 9 and optional transverse walls 10 can be divided into separate contact carriers cabin. In the illustrated embodiment, the configuration of the relay contact system is very simple, consisting of a movable spring contact 3 and a fixed spring contact 11 . The movable spring contact 3 can be bent horizontally and moved by a comb-like slide 2 arranged parallel to the bottom plane 1 . At the end opposite to the movable spring contact 3 and the fixed spring contact 11, the slide plate 2 has an armature protru...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com