Torsion spring and shell using the torsion spring

A shell and torsion spring technology, applied in the field of torsion springs and shells using the torsion springs, can solve problems such as spring instability, harsh industrial needs, and inability to meet

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

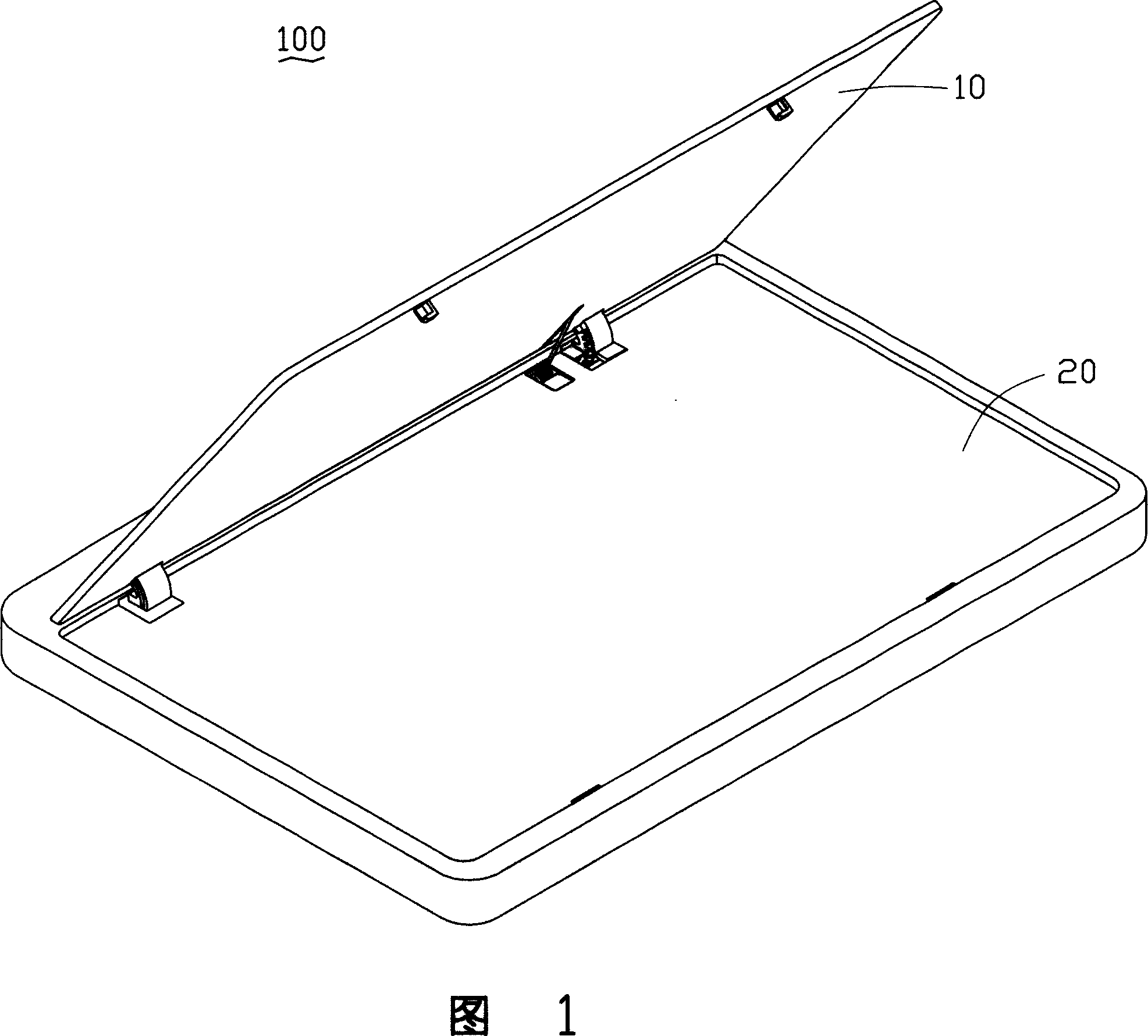

[0020] Please refer to FIG. 1 and FIG. 2 at the same time. The casing 100 of the preferred embodiment of the present invention includes a cover 10 , a body 20 , a first torsion spring 30 and a second torsion spring 40 . The cover 10 is pivotally connected to the body 20 . The cover 10 can rotate relative to the body 20 around a shaft (not shown). The first torsion spring 30 and the second torsion spring 40 are fixed on the shaft to provide power for the rotation of the cover 10 . During the rotation of the cover 10 around the body 20, the casing 100 can be in three states: a closed state, in which the cover 10 completely covers the body 20; a fully open state, in which the cover 10 is opposite to each other. When the body 20 is opened to the maximum opening angle; the half-open state is a state between the closed state and the fully open state, in which the cover body 10 is opened relative to the body 20 but has not reached the maximum opening angle.

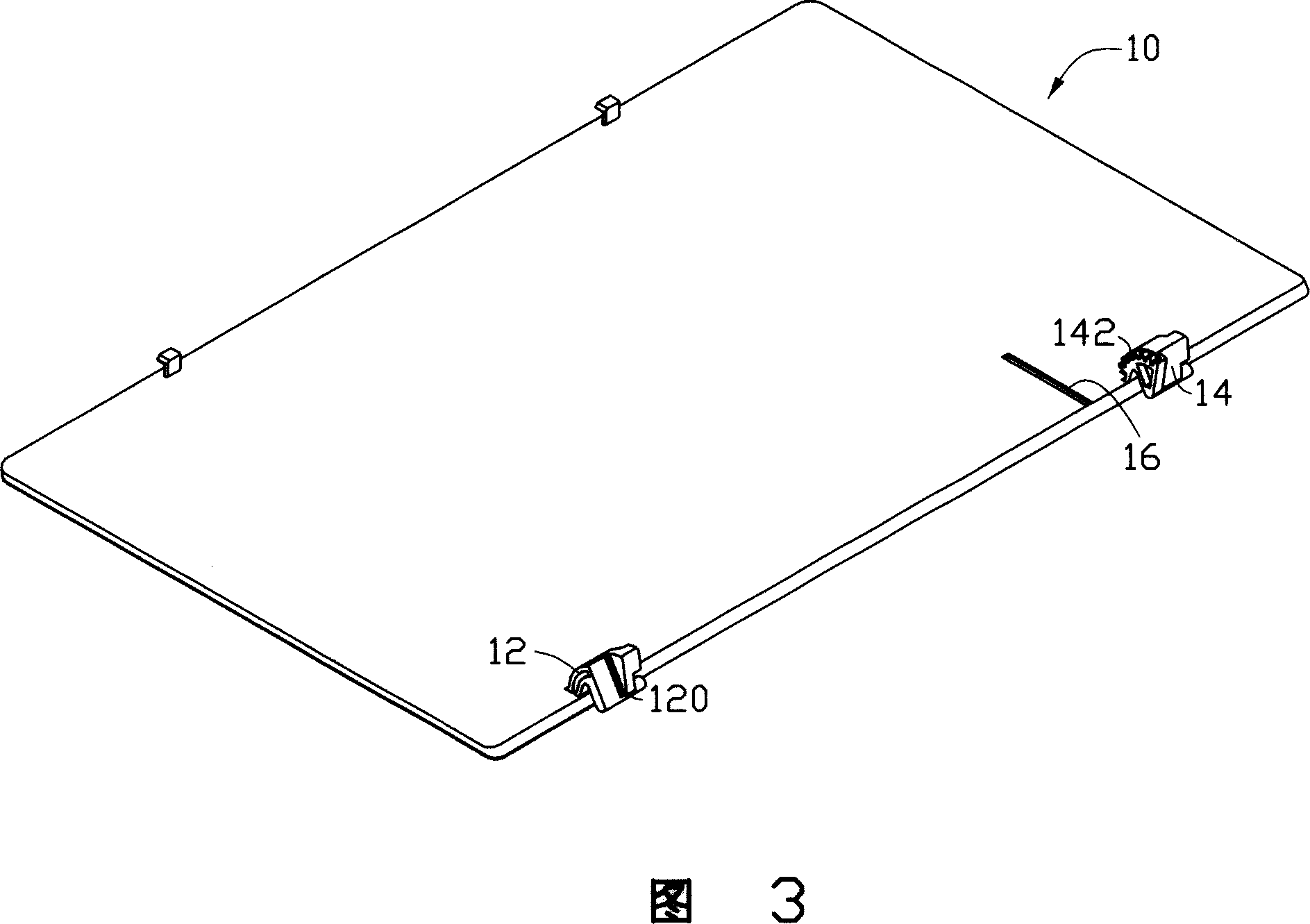

[0021] Please refer to F...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com