Tobacco seedling filed transplanter

A field and tobacco seedling technology, applied in the field of agricultural production machinery, can solve the problems of tobacco seedlings difficult to return to seedling growth, poor transplanting quality, labor occupation, etc., and achieve the effect of simple operation, complete functions, and improved standardization level

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

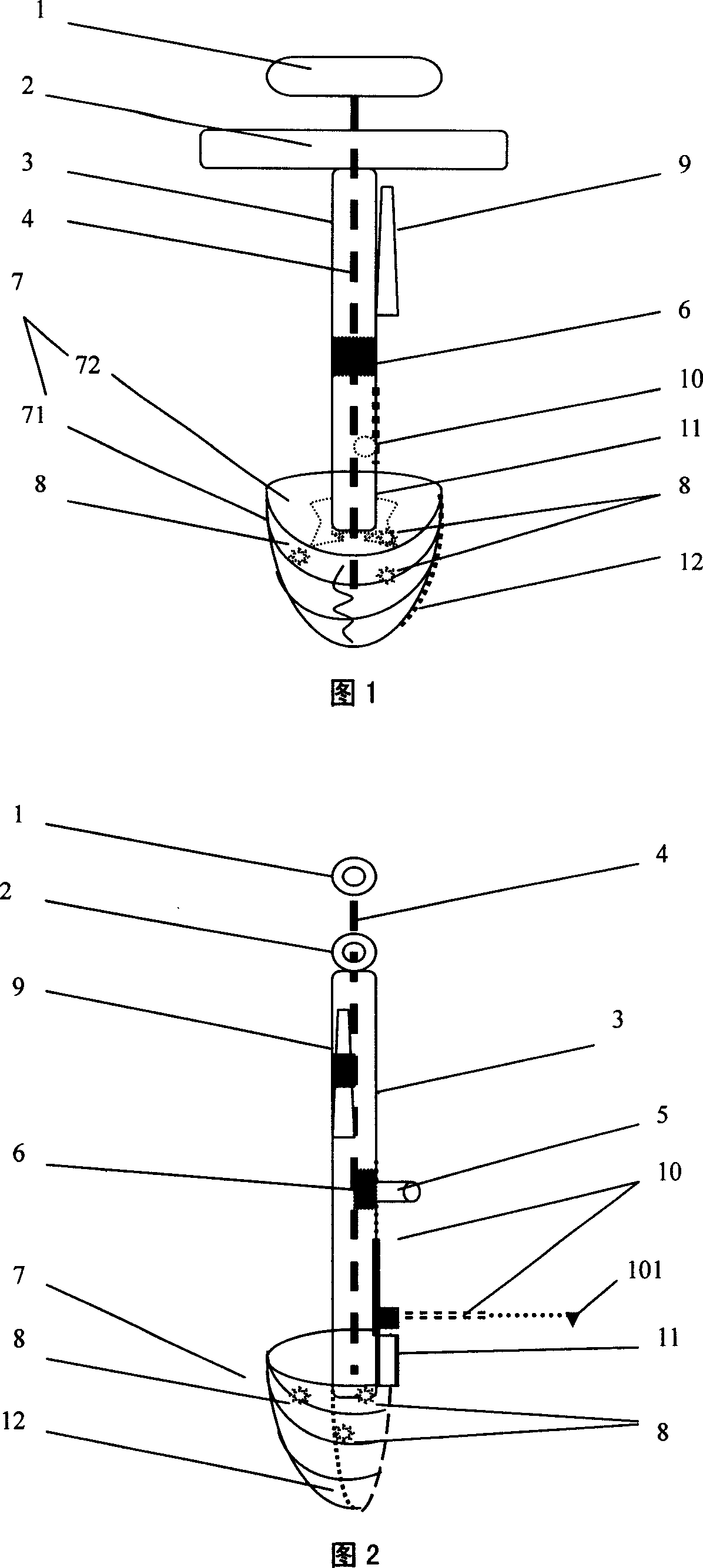

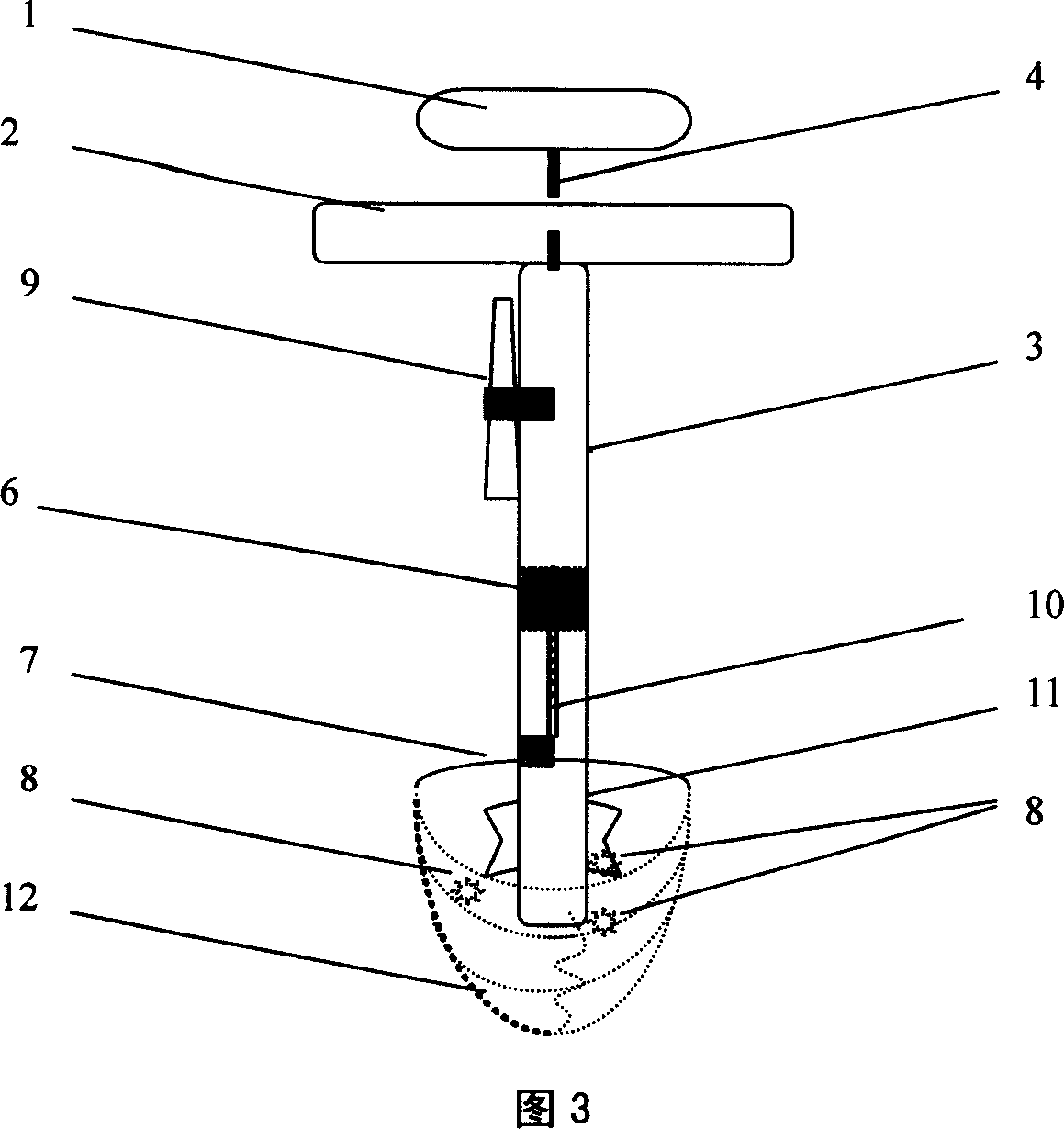

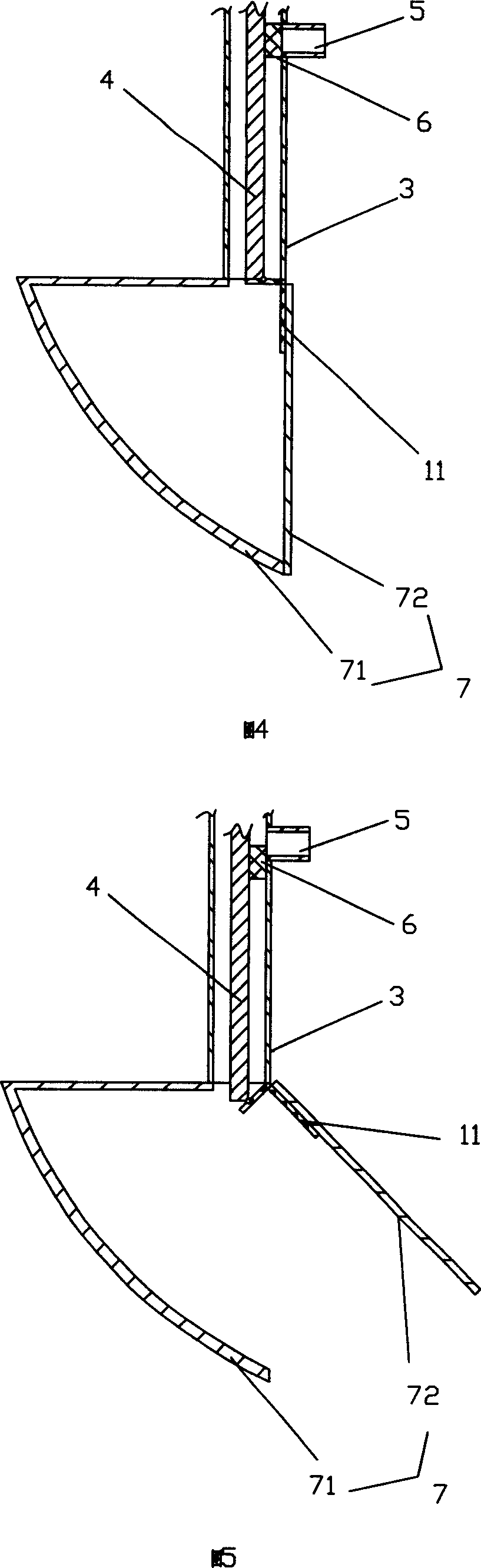

[0018] The structure of the field transplanter for tobacco seedlings described in this embodiment is shown in Figures 1, 2, 3, 4, and 5, wherein the upper end of the main rod 3 is connected with a T-shaped handle 2, and the main rod 3 passes through it. The water pipe connector 5 connected to the water pipe, the lower end of the main rod 3 is connected to a hole opener 7 that is tapered gradually from top to bottom and is composed of two sheet body front plates 71 and back plates 72. Wherein the front plate 71 is fixed on the main rod 3 . The control shaft 4 is passed through the through hole 30 provided by the handle 2 and the main rod 3 and inserted into the handcuff chain 11 provided on the hole opener 7. One end of the handcuff chain 11 is hinged to the control shaft 4, and the other end is fixed to the hole opening The rear plate 72 of the device, the middle part of the handcuff chain 11 is hinged on the main rod 3.

[0019] The main rod 3 is provided with a water pipe j...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com