Two stage low pressure method for coal bed gas producing natural gas

A coalbed methane and natural gas technology, applied in the field of two-stage low-pressure coalbed methane production of natural gas, can solve problems such as energy waste and environmental protection, and achieve high recovery rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

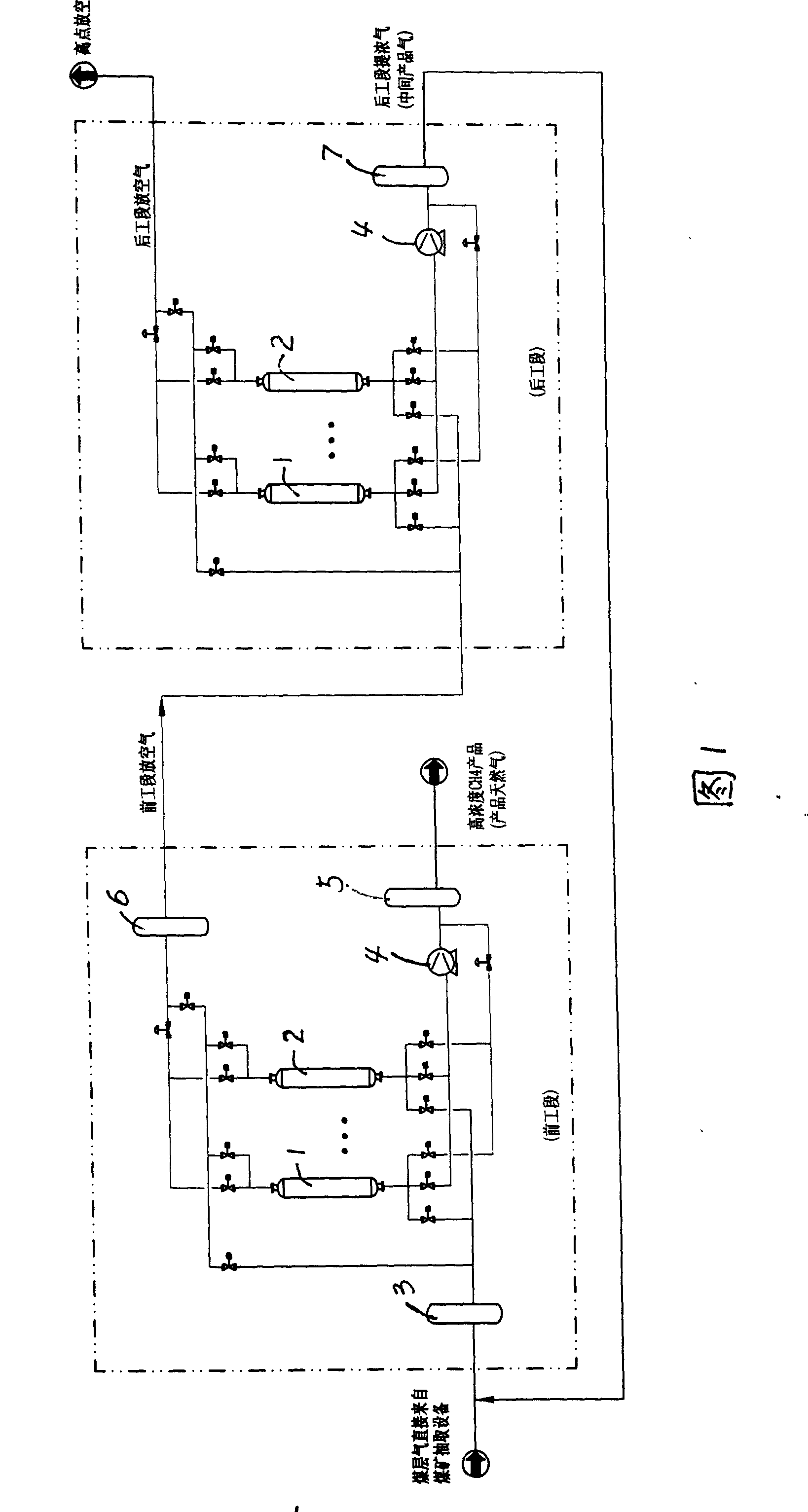

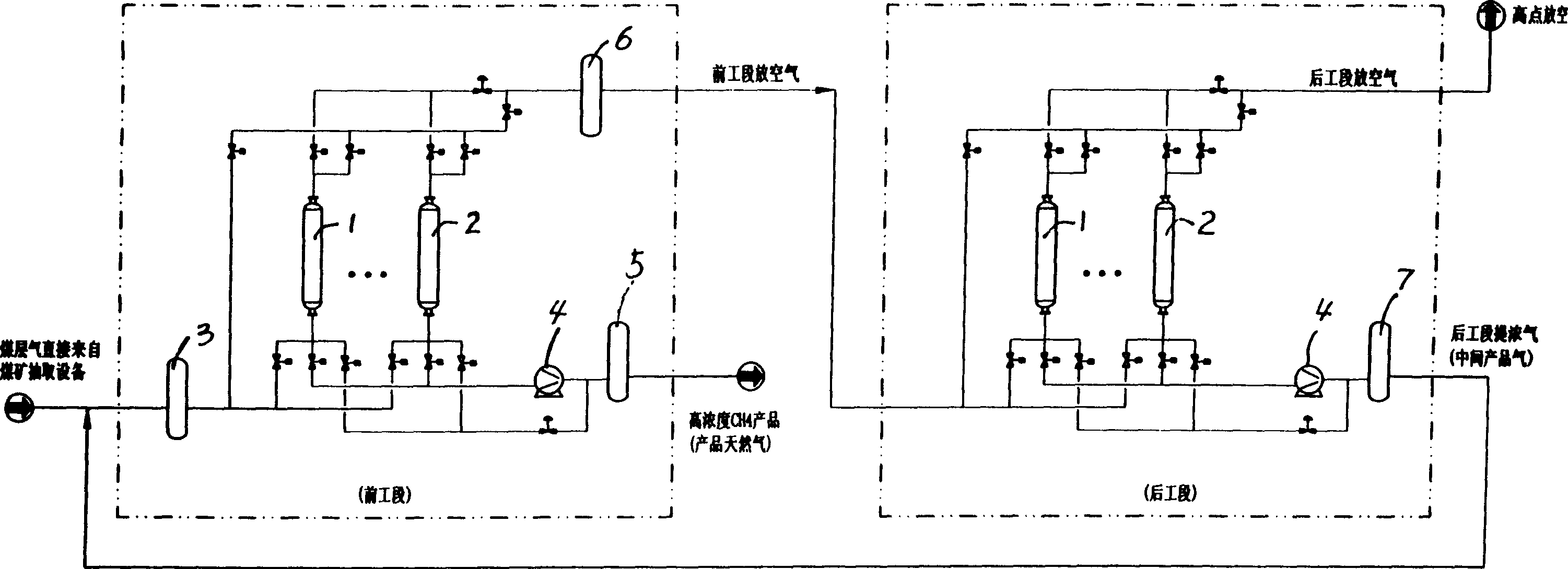

[0021] Embodiment 1, see attached figure 1 :

[0022] The first two-stage low-pressure coalbed methane production method for natural gas consists of two low-pressure CH 4 The gas adsorption and enrichment section is formed by series circulation; the product natural gas is produced in the former section, and the intermediate product after enrichment in the later section is returned to the previous section as raw material gas.

[0023] This method per CH 4 The gas stripping and concentration section consists of 2 filled with 2-3 kinds of CH 4 It consists of an adsorption tower for gas adsorbent, a buffer tank, a vacuum pump and several program-controlled valves for switching control. The front section is equipped with a raw material buffer tank 3, a vacuum pump 4, a natural gas buffer tank 5, and an air release buffer tank 6; the rear section is equipped with a vacuum pump 4 and an intermediate product buffer tank 7. The adsorbent in the adsorption tower is silica gel, activ...

Embodiment 2

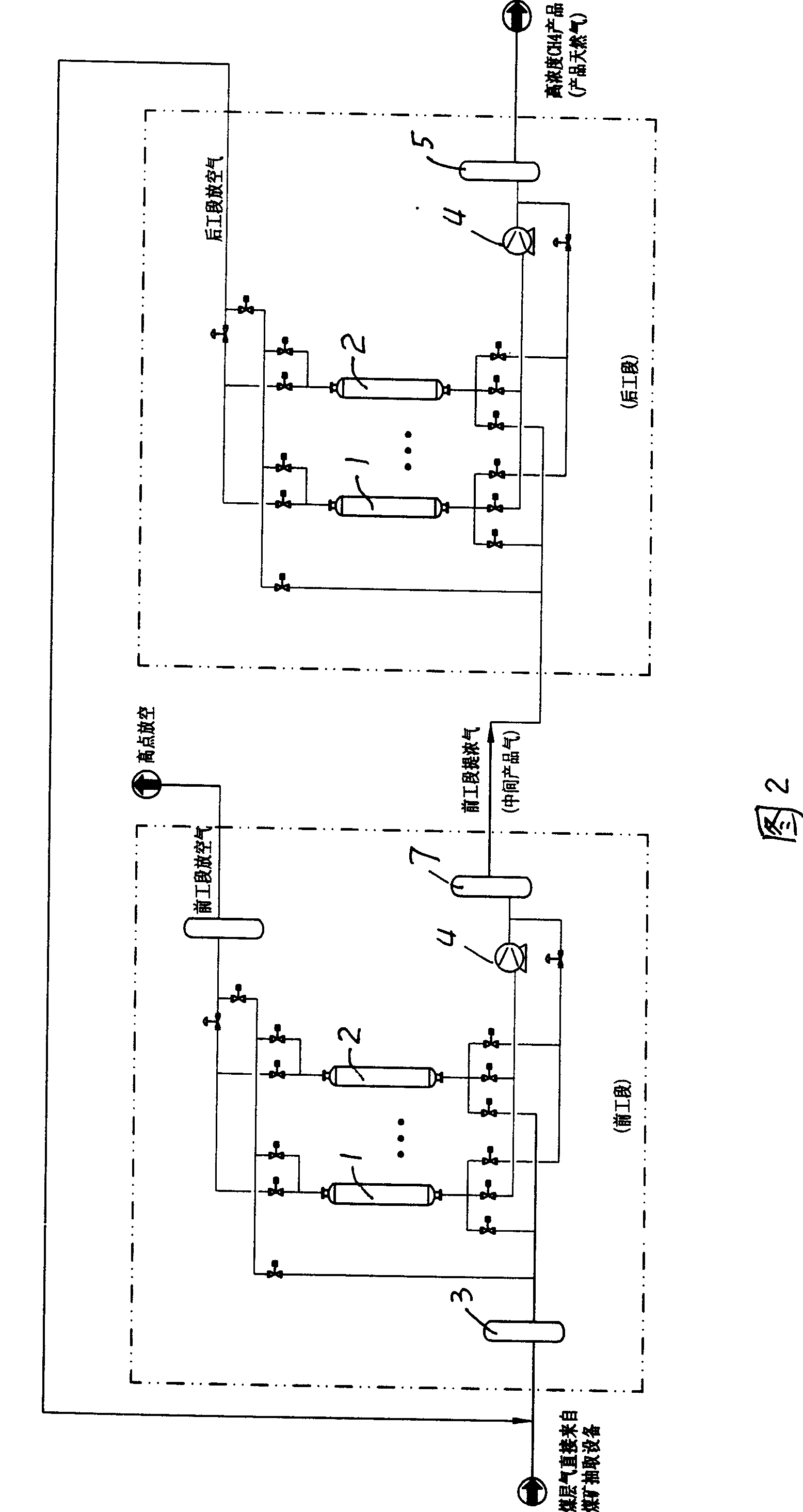

[0030] Embodiment 2, see attached figure 2 :

[0031] The second two-stage low-pressure coalbed methane production method consists of two low-pressure CH 4 The gas adsorption and enrichment section is formed by series circulation; the coalbed methane is initially purified in the front section to obtain intermediate product gas, and then the intermediate product gas is used as the raw material of the subsequent section to purify natural gas, and the air released in the latter section is returned to the previous section as raw material gas.

[0032] The front section adopts the intermediate product buffer tank 7, and others are the same as in embodiment 1; the rear section adopts the natural gas buffer tank 5, and the others are the same

[0033] Both the front section and the back section adopt the following vacuum regeneration process, as follows:

[0034] The second two-stage low-pressure method for producing natural gas from coalbed methane. The coalbed methane from the coa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com