Manually driven surgical cutting and fastening instrument

A surgical instrument and driver technology, which is applied in the directions of surgical instruments, external fixators, surgical fixation pins, etc., can solve the problems of high cost and the like

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

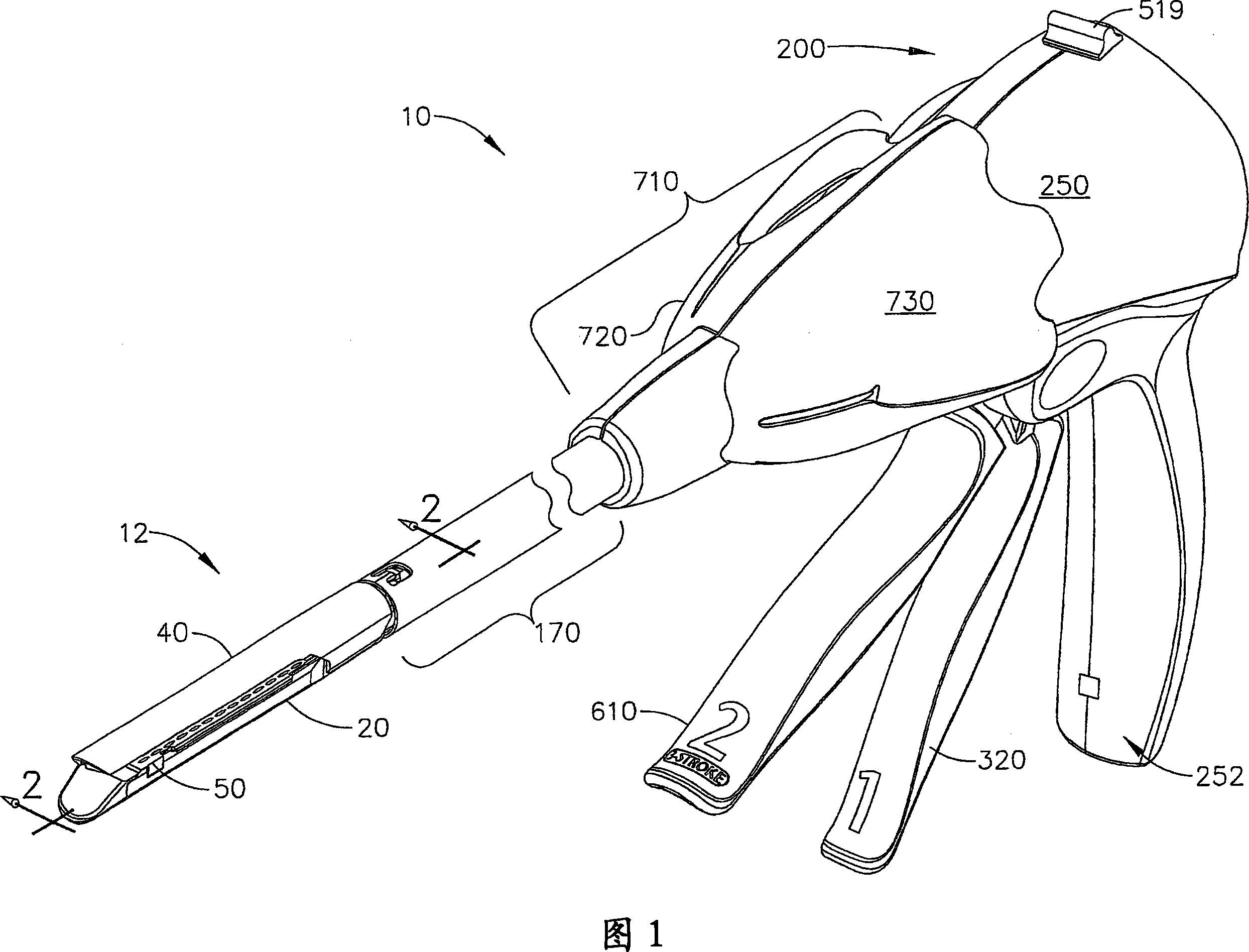

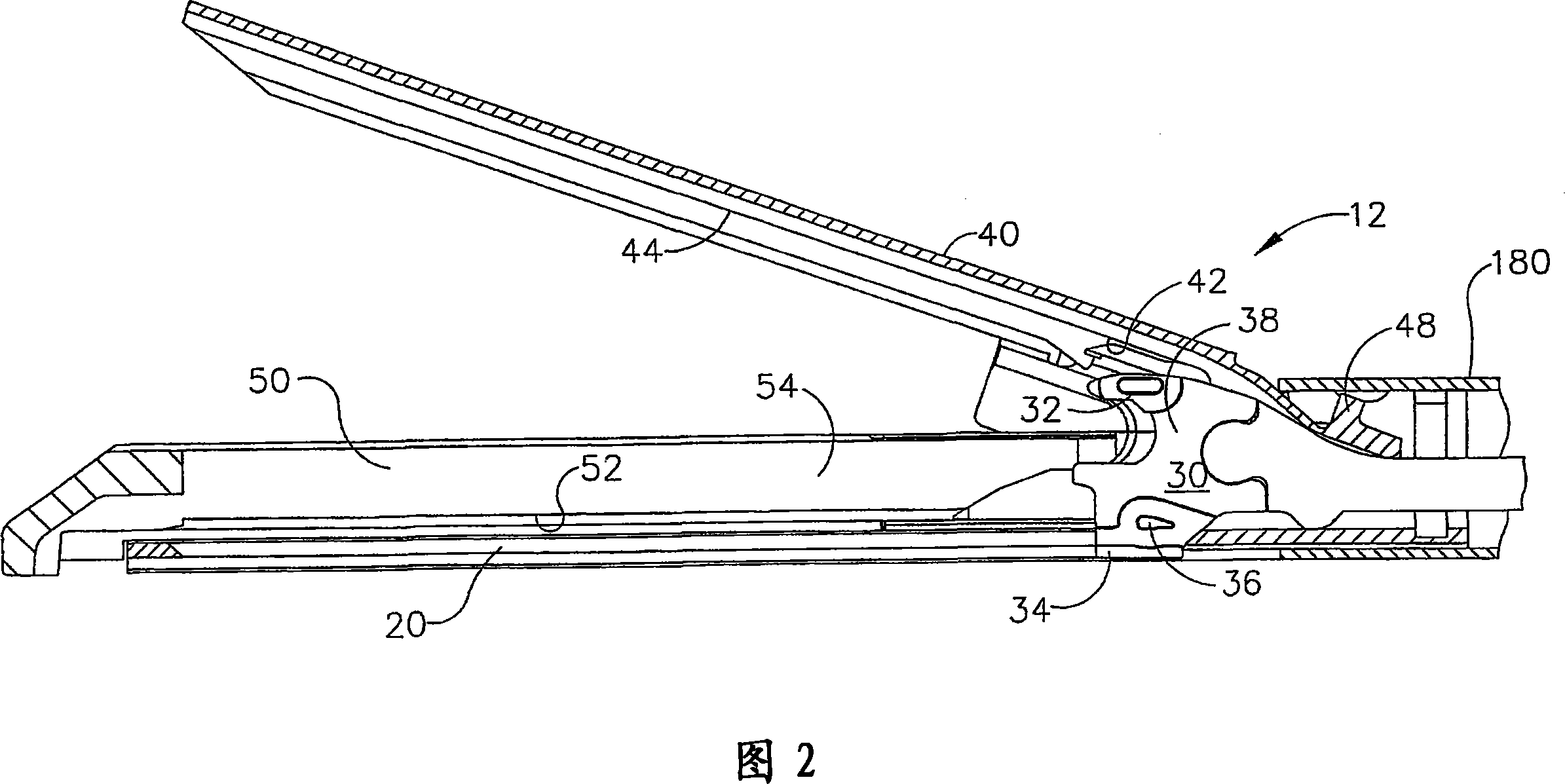

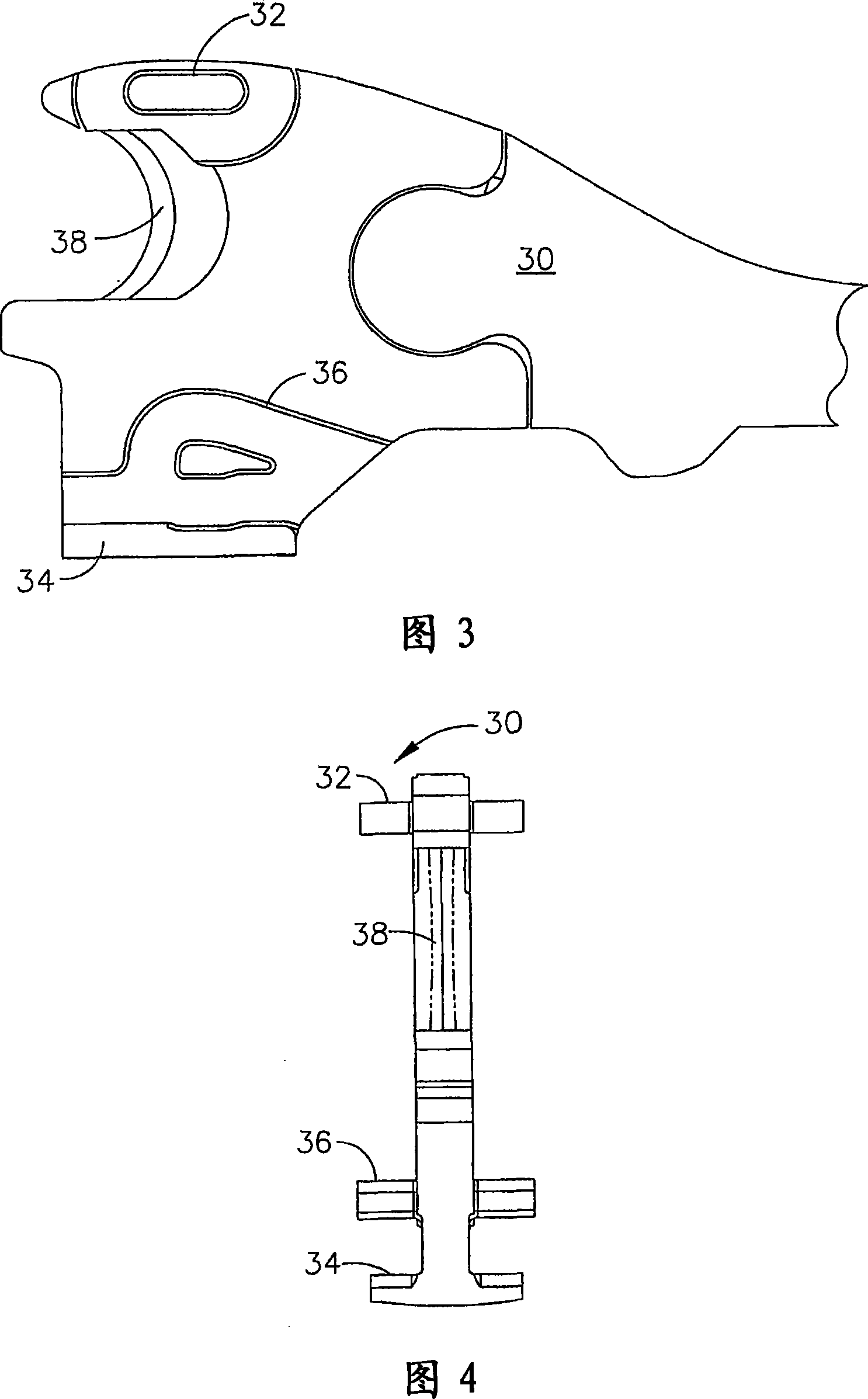

[0095] Turning to the drawings, in which like numerals represent like elements throughout, FIG. 1 illustrates a surgical stapling and cutting instrument 10 that is capable of practicing some of the unique advantages of the present invention. The surgical stapling and cutting instrument 10 includes an end effector 12 that is manually actuated by operation of a control member on a handle assembly 200 coupled thereto. A variety of different end effector configurations are known. One type of end effector 12 that may be used in various embodiments of the invention is shown in FIGS. 1 , 2 and 5-9. As shown in some of those figures, end effector 12 employs an E-beam firing mechanism ("firing bar") 30 that advantageously controls the spacing of end effector 12 . Various aspects of the E-beam firing mechanism are described in US Pat. No. 6,978,921 to Shelton IV et al., entitled Surgical Stapling Instrument Incorporating an E-Beam Firing Mechanism, the relevant parts of which are incor...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com