Oxygen-iodine chemical laser ultrasonic oxygen iodine mixing spraying pipe with nitrogen as the dilution gas

A technology of oxygen iodine chemistry and diluent gas, applied in laser parts and other directions, can solve the problems of high cost of use, inability to adapt to applications, rare helium resources, etc., and achieve the effect of reducing operating costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

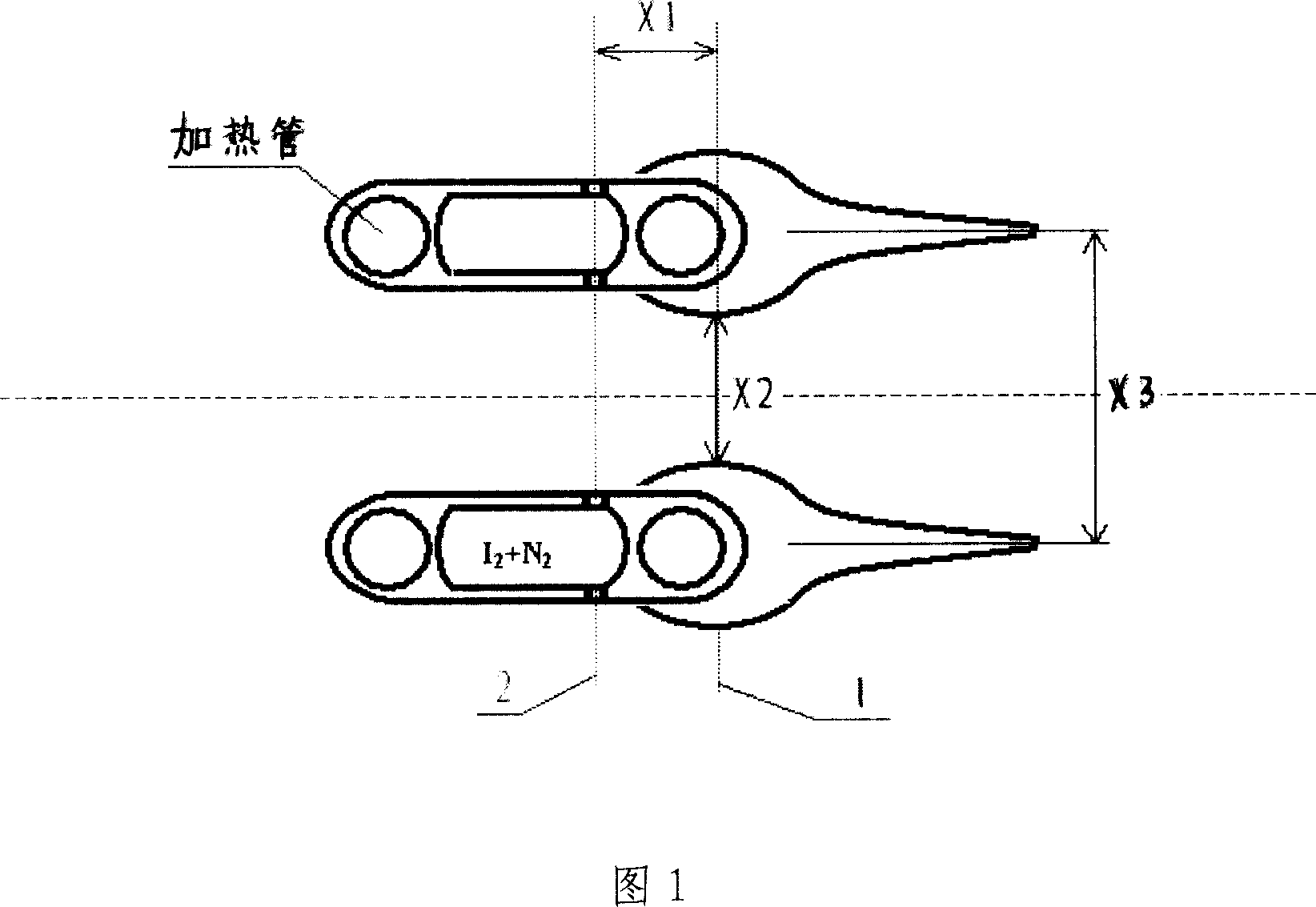

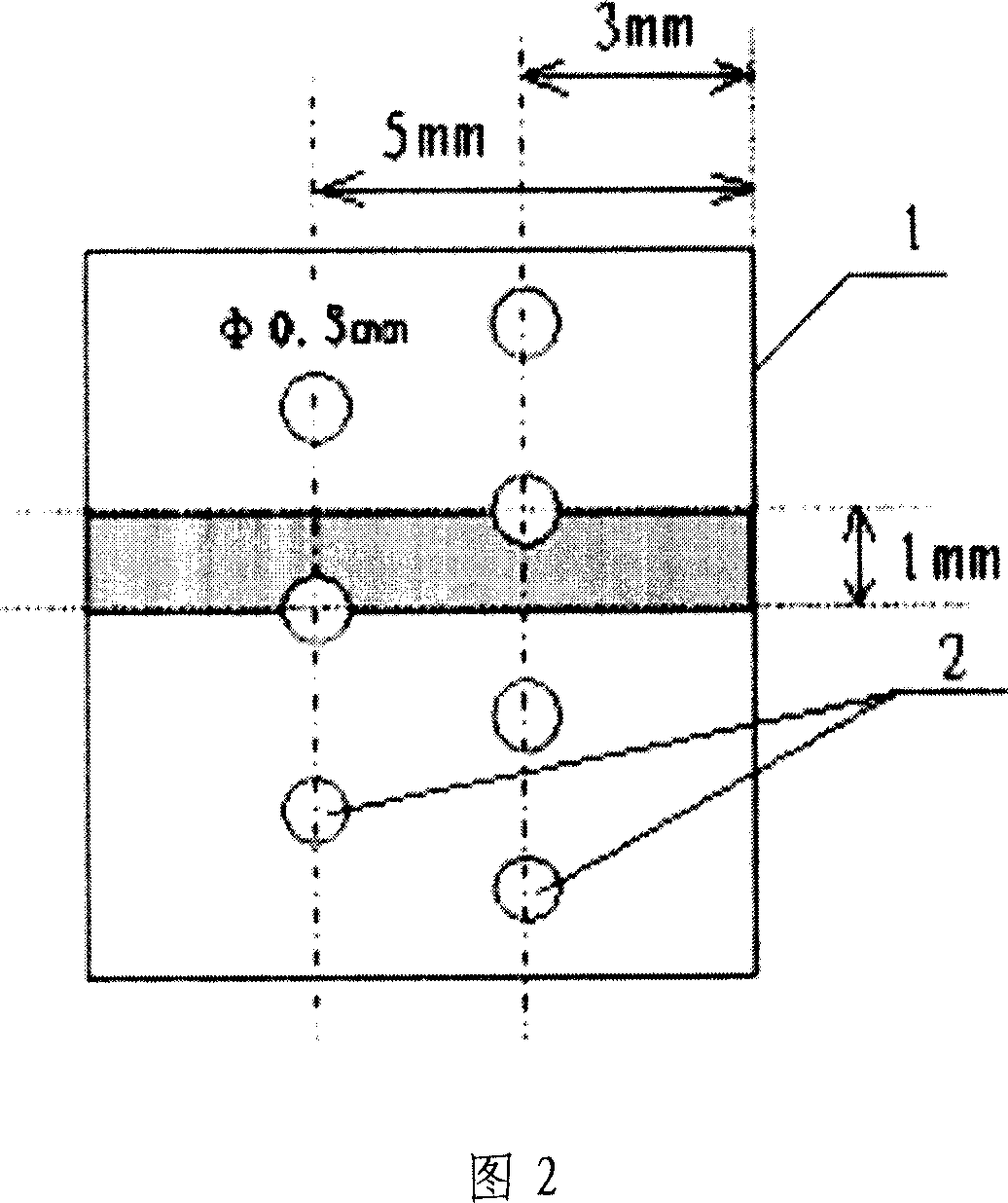

[0017] As shown in the figure, there are two rows of iodine nozzles 2 in the subsonic section of the nozzle, the diameter of which is Φ0.5mm, the distance between the two rows of iodine nozzles is 2mm, and the distance between the two rows of nozzles 2 and the nozzle throat 1 The average distance X1 is 3mm; the design Mach number of the nozzle outlet is 2.2, the corresponding nozzle width X2 of each unit of the nozzle is 4mm, and the width X3 of the nozzle outlet is 10mm.

Embodiment 2

[0019] There are two rows of iodine nozzles 2 in the subsonic section of the nozzle, the diameter of which is Φ0.5mm, the distance between the two rows of iodine nozzles is 2mm, and the average distance X1 between the two rows of nozzles 2 and the nozzle throat 1 is 4mm ; The design Mach number of the nozzle outlet is 2.5, the corresponding throat width X2 of each unit of the nozzle is 5mm, and the width X3 of the nozzle outlet is 13mm.

Embodiment 3

[0021] There are two rows of iodine nozzles 2 in the subsonic section of the nozzle, the diameter of which is Φ0.5mm, the distance between the two rows of iodine nozzles is 2mm, and the average distance X1 between the two rows of nozzles 2 and the nozzle throat 1 is 5mm ; The design Mach number of the nozzle outlet is 2.8, the corresponding nozzle width X2 of each unit throat is 6mm, and the width X3 of the nozzle outlet is 15mm.

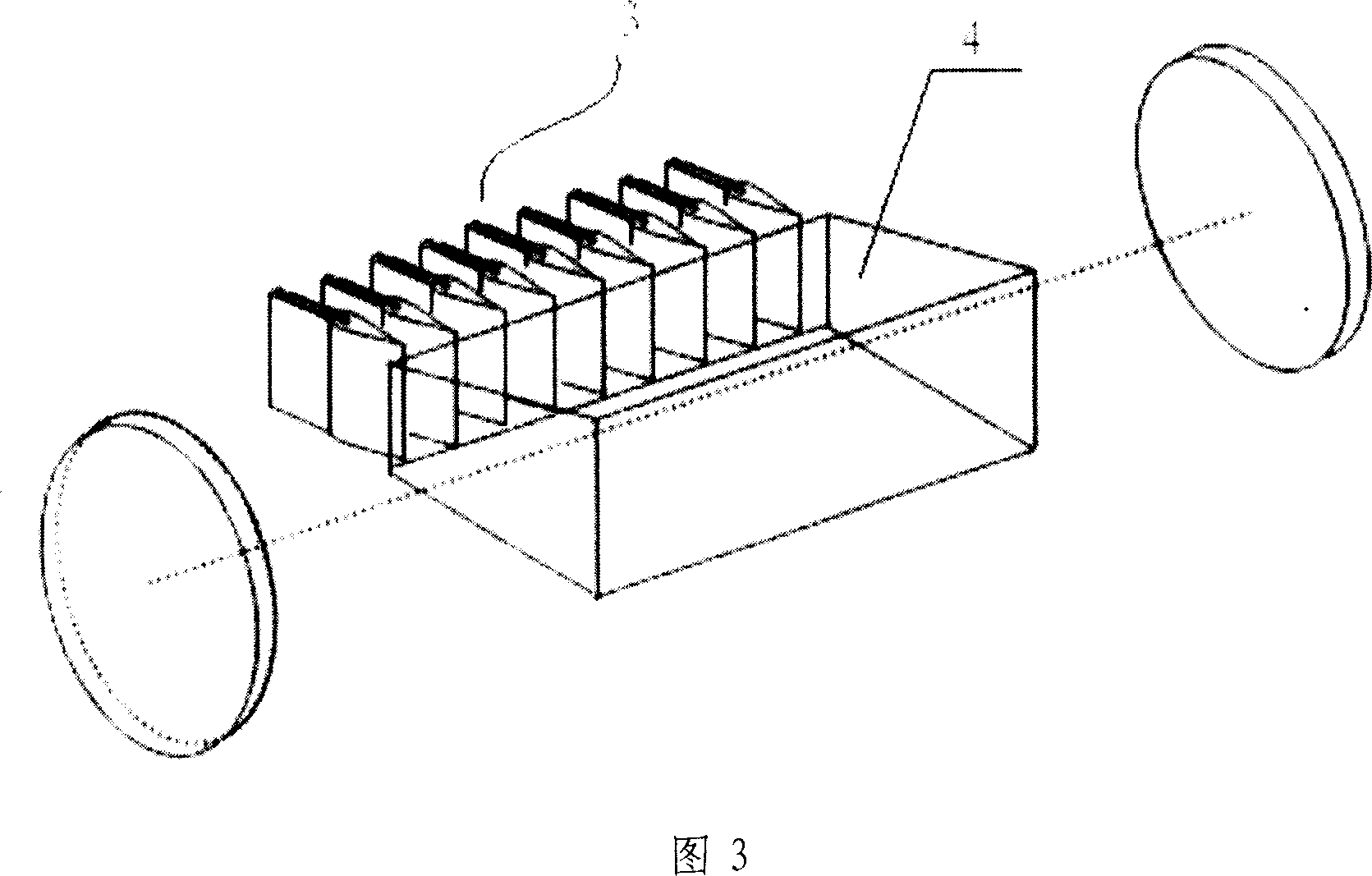

[0022] The supersonic oxygen-iodine mixed nozzle designed with the shape and geometric dimensions of the nozzle corresponding to the above design parameters can use nitrogen as the diluent gas or no diluent gas, and a low-temperature molecular sieve adsorption pump can also be used as the pressure recovery system.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com