Method of drying molds and apparatus for supplying drying air

A dry air and dry technology, applied in applications, household appliances, other household appliances, etc., can solve problems affecting the quality of contact lenses, long life of half-mold edges, difficulty in automatic loosening of contact lenses, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

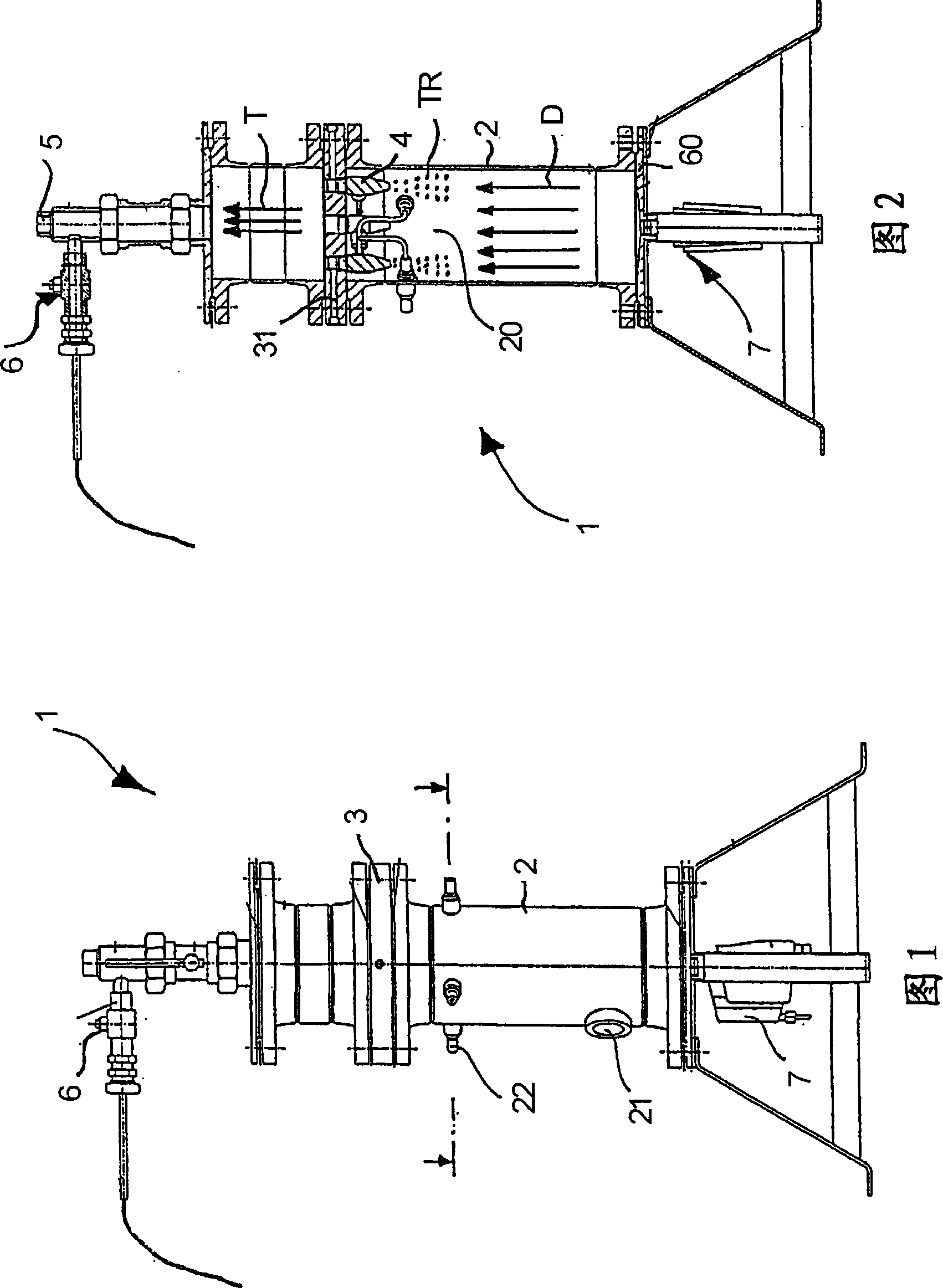

[0027] exist figure 1 with 2 In , an embodiment of the device 1 for supplying moist drying air T according to the invention is shown in side view and in section, respectively. In particular, the tube 2 can be seen, in which a humidification chamber 20 is arranged. The duct 2 is provided with an inlet 21 for substantially dry pressurized air D through which the air will be introduced into the humidification chamber 20 . The pressurized air inlet 21 is arranged in the region of the lower end of the tube 2 . The relative humidity of the substantially dry pressurized air D may be practically zero or in the range of a few percent. The pressure at which the pressurized air D is introduced can be, for example, 1 bar, but this pressurized air can also be at a different pressure, especially a higher pressure (especially with regard to the fact that in industrial installations the supply pressure is often 6 bar The pressurized air) is supplied.

[0028] The pipe 2 is also provided ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com