Improved structure of nail-slot nail-ejection of nailing machine

A nailing machine and nail groove technology, applied in nailing tools, nailing staple tools, manufacturing tools, etc., can solve the problem of hitting two T-shaped nails at the same time, and achieve the effect of improving the service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

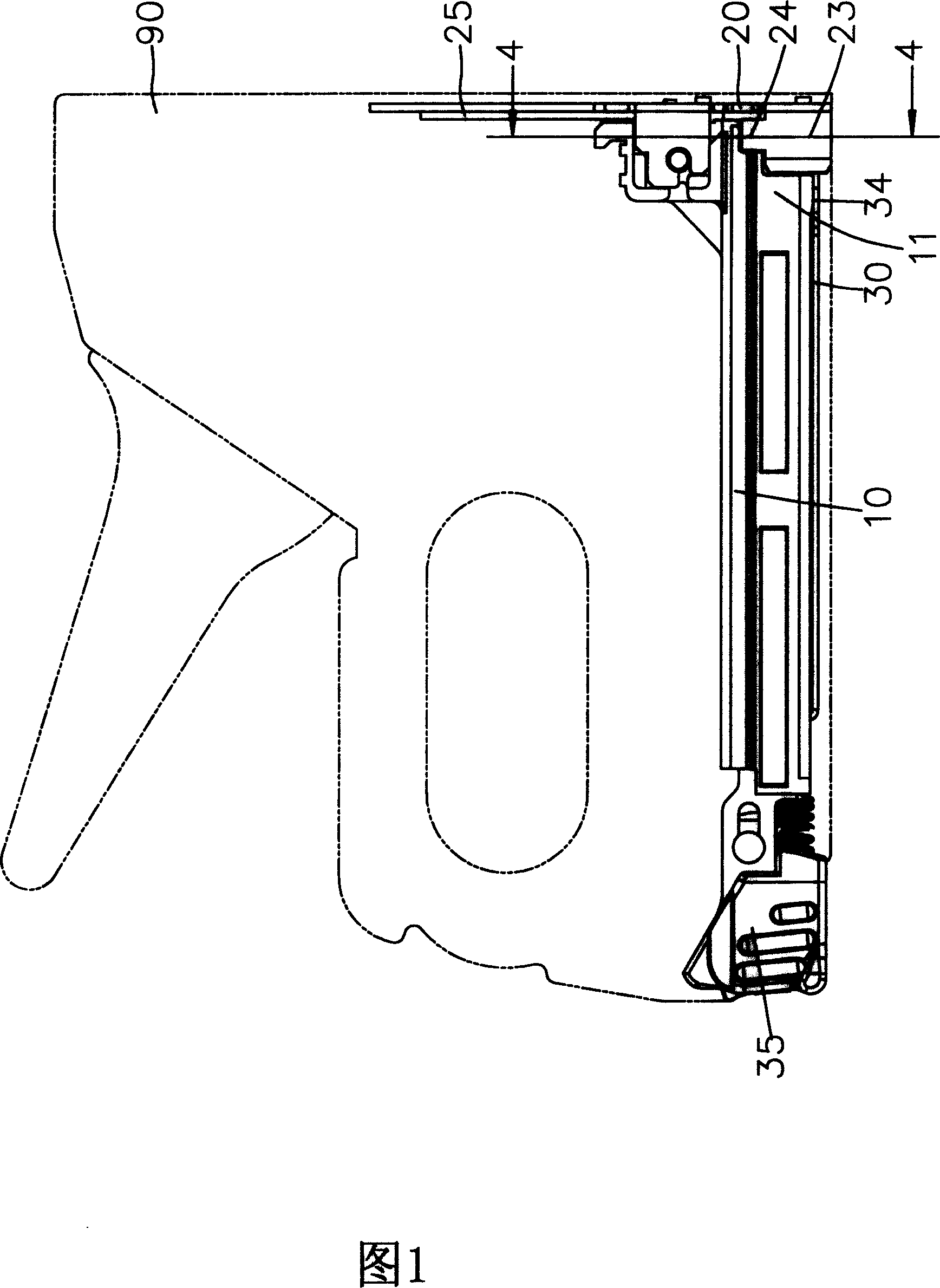

[0022] Regarding the technology, means and effects adopted in the present invention, a preferred embodiment is given and described in detail below with drawings, which are for illustration only, and are not limited by this structure in the patent application.

[0023] With reference to Fig. 1 and Fig. 2, the present invention comprises an outer groove seat 10 that is located on the gun body 90, a guide cover 20 that is installed on the front end of the outer groove seat 10 and an inner groove seat 30 that is located at the inside of the outer groove seat 10; The guide cover 20 is provided with a supporting end 24 to provide a good supporting effect for the T-shaped nail 91 (as shown in FIG. 6 ). in:

[0024] Please refer to Fig. 3 and Fig. 4, described outer groove seat 10 is installed on the bottom of gun body 90 (as Fig. 1), and described outer groove seat 10 is provided with two mutually parallel first side walls 11 and the second side wall 12, and a top 13 perpendicular t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com