Syringe

A technology of syringes and couplers, which is applied in the field of syringes, can solve problems such as complexity and increased production costs of syringes, and achieve the effect of avoiding secondary use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

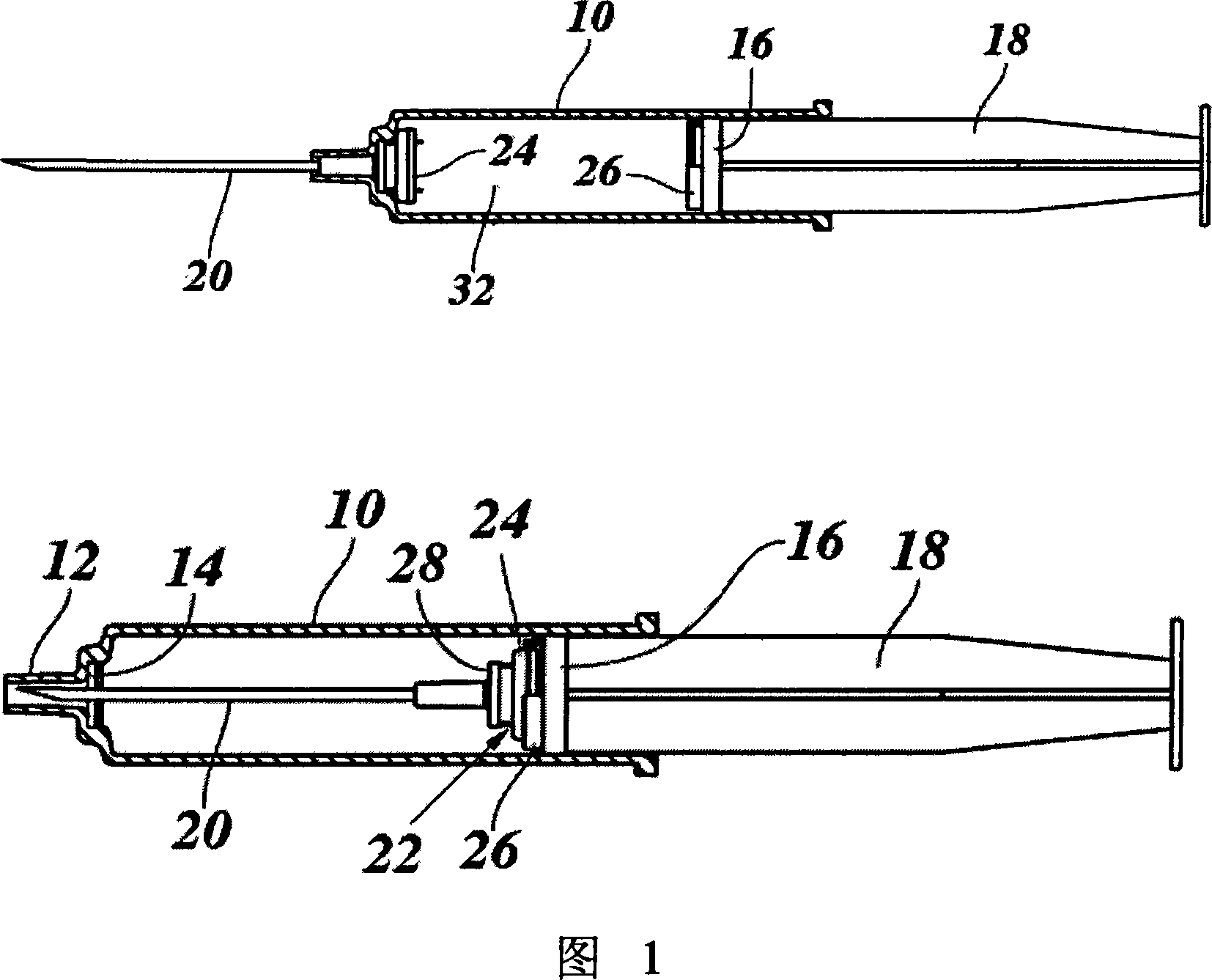

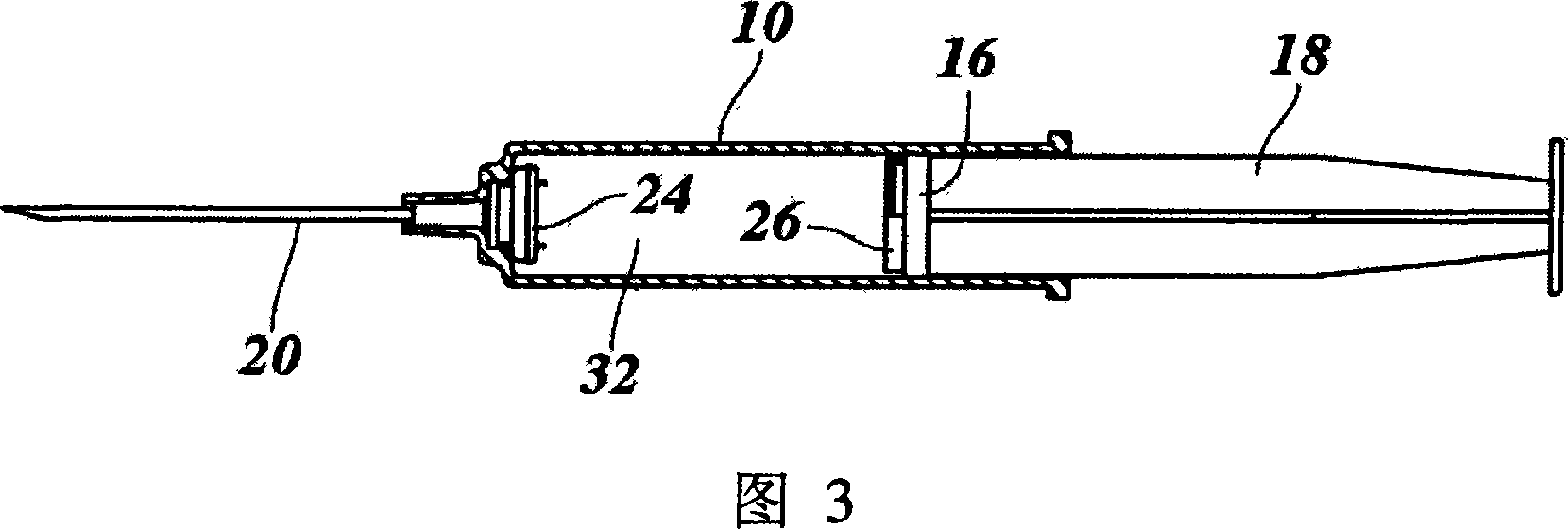

[0021] The syringe shown in FIG. 1 is made of plastic to form a cylindrical barrel 10 , the front of which is contracted to form a port 12 . At the distal end of the barrel, there is an annular groove on its inner surface to form a self-locking device, located between the port 12 and the main body of the barrel 10 .

[0022] A disc-shaped piston 16 is at the end of the stem and slides within the cylindrical barrel.

[0023] As shown in FIG. 1, the needle tube 20 is located inside the barrel with the tip positioned therein and protected by the port. The rear of the needle tube 20 is in contact with the piston through a connection 22 . The coupler 22 consists of a needle end portion 24 and a piston end portion 26 . In Figure 1, these devices are in a freely connected state, and there is mutual thrust between the piston and the needle tube. When the piston is withdrawn, the force between the two disappears. This section of the connecting device 24 has an annular protrusion 28...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com