Internal combustion engine control device and methd

A control device, a technology for an internal combustion engine, applied in engine control, fuel injection control, internal combustion piston engine, etc., can solve the problem of difficult to accurately predict the fuel amount, the deviation of the air-fuel ratio from the target value, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

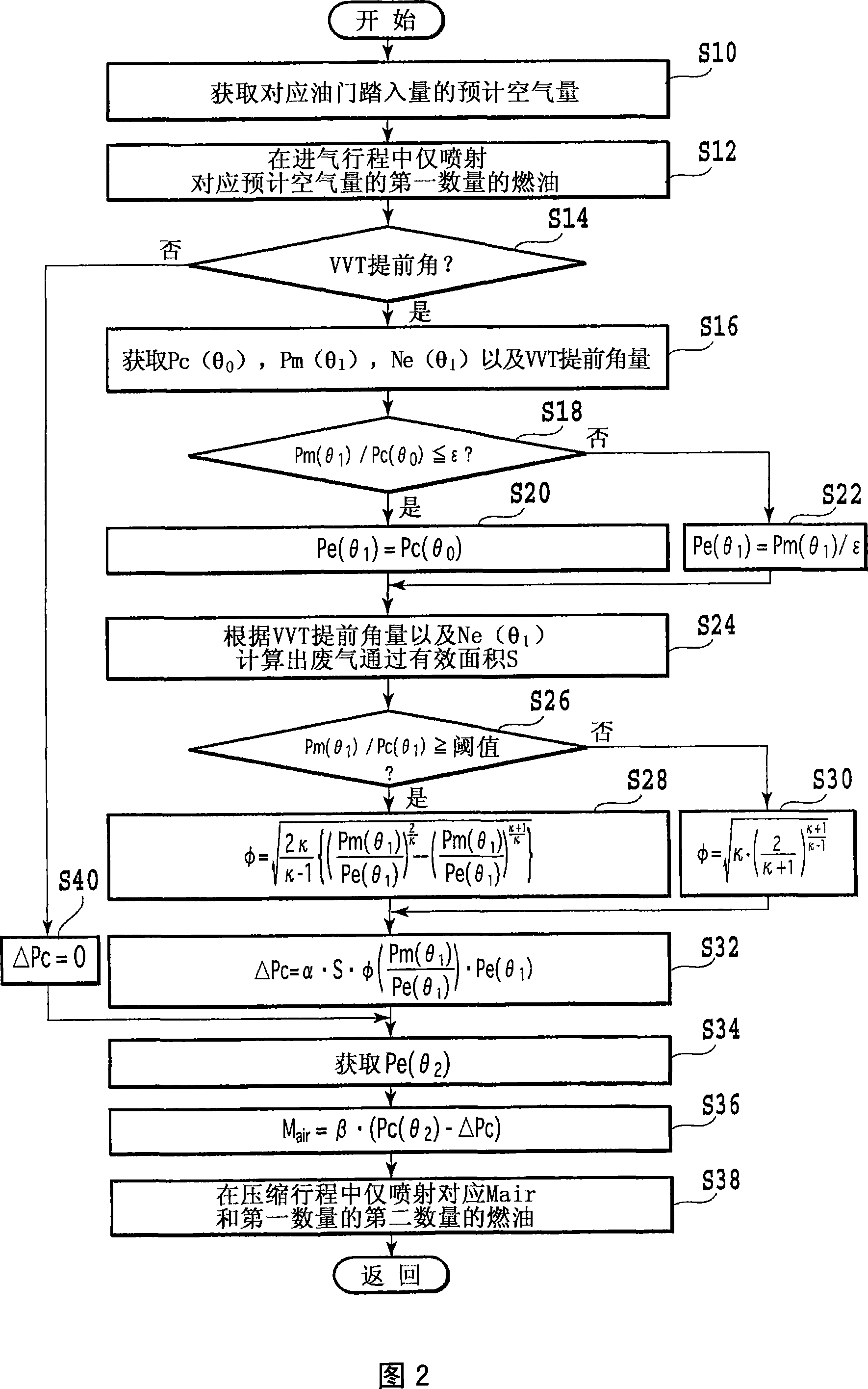

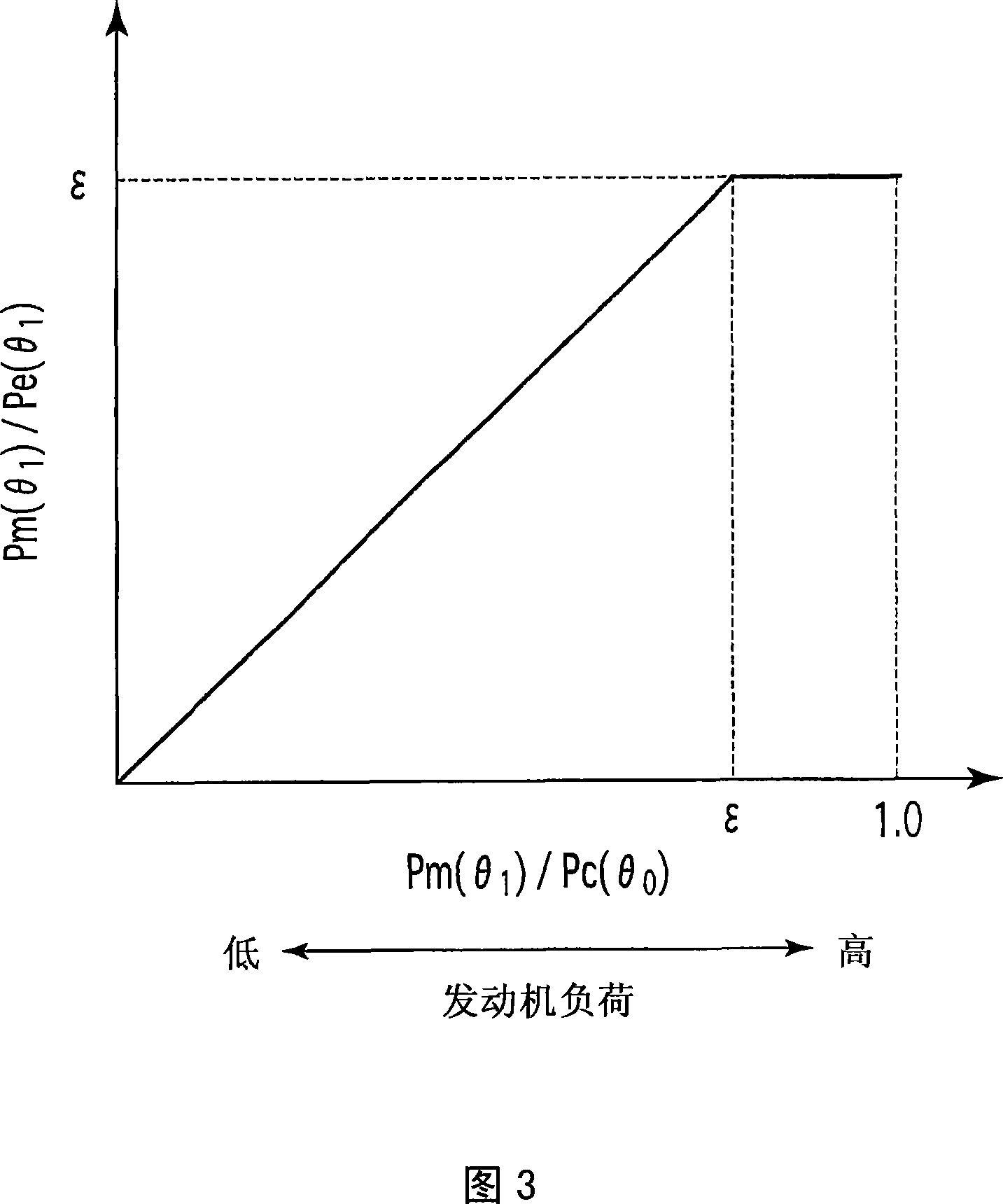

[0016] In the internal combustion engine using the control device of the present invention, for example, when the predetermined timing before the intake valve opens is reached, the estimated air amount estimation means is used to estimate the estimated air amount that meets the requirements for the internal combustion engine. After estimating the estimated air amount, the fuel injection control unit controls the fuel injector to inject fuel according to the estimated air amount so that the air-fuel ratio of the mixture in the combustion chamber is less than or equal to the target value of the initial injection amount of fuel. Then, the amount of air sucked into the combustion chamber is calculated by the intake air amount calculation unit based on the in-cylinder pressure in the combustion chamber at a predetermined timing before the start of combustion in the compression stroke. And, when the intake air amount is calculated, the fuel injection control unit injects from the inj...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com