Simple measurement method for rock structural plane roughness coefficient

A technology of roughness coefficient and measurement method, applied in the direction of measuring devices, instruments, etc., can solve the problems of tediousness, slow measurement speed, complex calculation formula, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

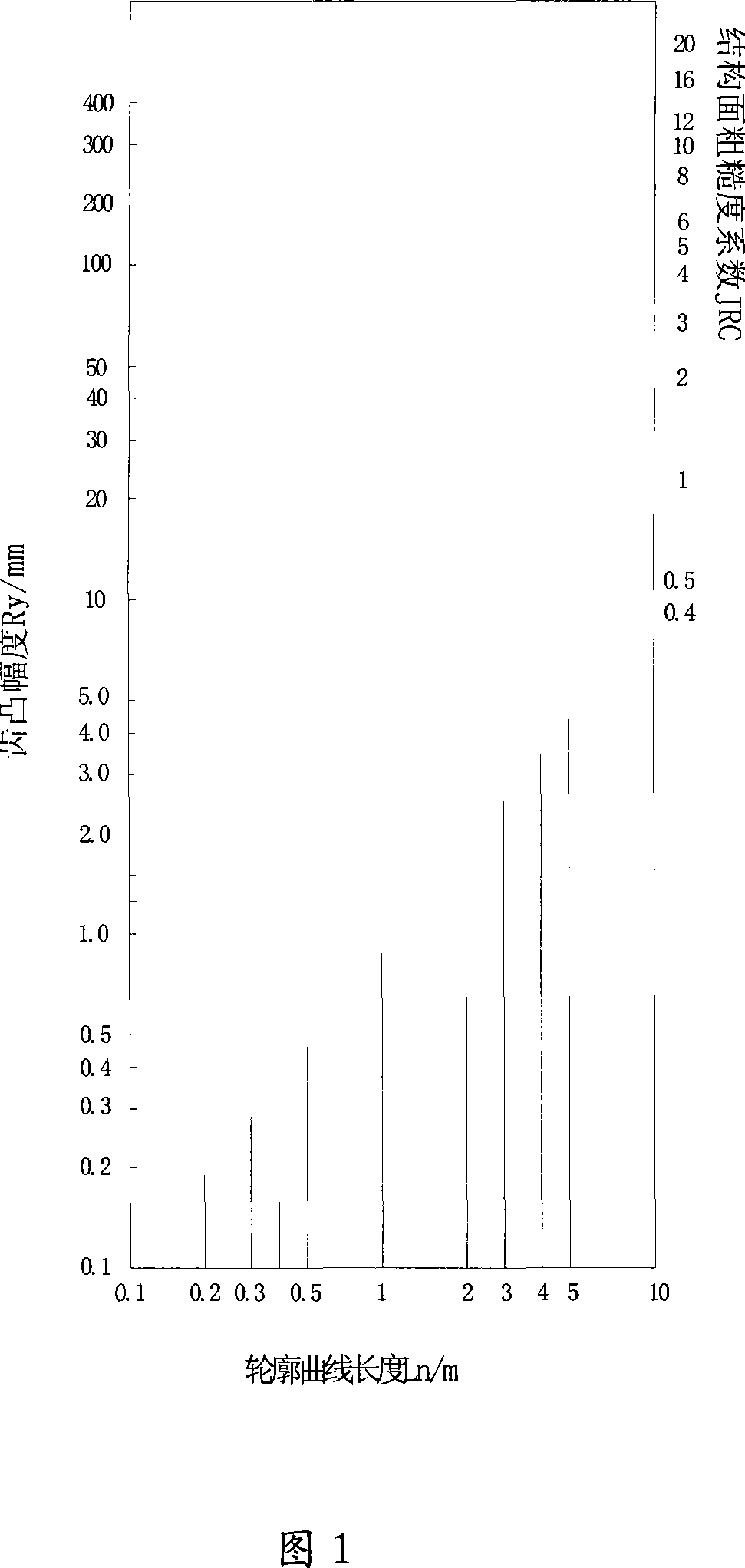

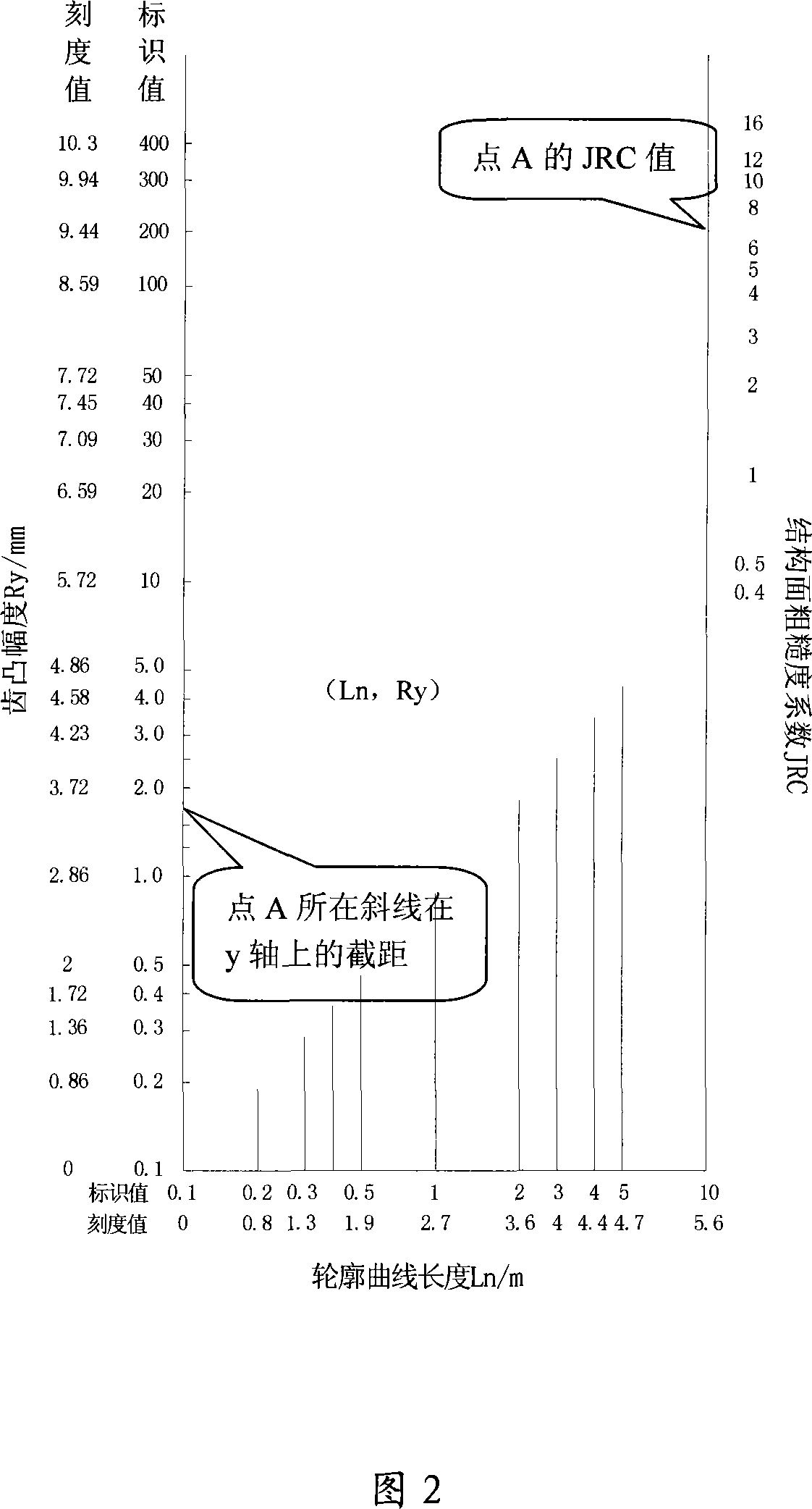

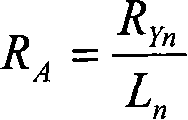

[0058] Table 7 is an embodiment of the present invention. According to the different sampling lengths of Lin'an Dashigu tuff joints, the tooth convex amplitude R of the structural surface profile curve yn The measurement result of , without the aid of a calculator or computer, can be obtained from the formula R A = R Y n L n Calculate the sampling length as L n The relative convex tooth amplitude value R of the surface profile curve of the rock structural plane A and formula JRC n =400R A The calculated sampling length is L n The roughness coefficient JRC of the surface contour curve of the rock structural surface n , and the measurement results are listed in Table 7. Table 7 shows the roughness coefficient values of structural planes with different sampling lengths in Dashigu tuff joints i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com