Changing flow direction method for blocking reverse osmosis membrane fouling under the scale inhibitor existing

A technology of reverse osmosis membrane and scale inhibitor, which is applied in the field of membrane separation in chemical engineering science, can solve the problems of reverse osmosis membrane fouling, etc., and achieve the effects of reducing the number of chemical cleaning of the membrane, prolonging the life of the membrane, and preventing membrane scaling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

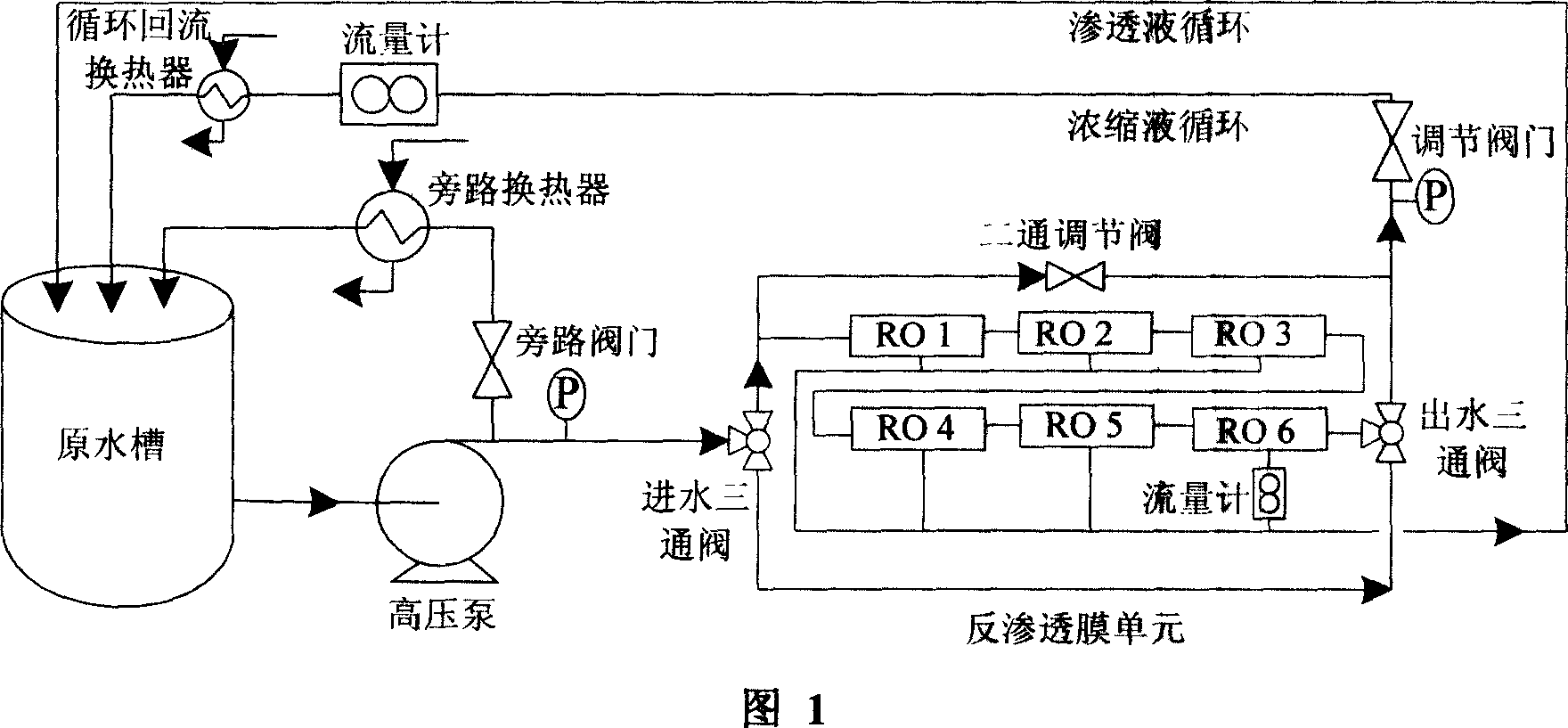

[0026] Install the reverse osmosis membrane unit, connect 6 membrane shells in series (RO1-RO6), and fill the membrane shells with ESPA-2521 membrane elements from Hyde Energy, as shown in Figure 1. In order to prevent the membrane element from moving due to the change of the raw water flow direction in the membrane casing, thrust rings are installed at both ends of the inlet and outlet of the membrane casing, and the thrust ring can well fix the membrane element in the membrane casing.

[0027] Connect the permeate pipelines of the 6 membrane shells in the reverse osmosis membrane unit, and collect and flow into the permeate pipelines. A flow meter is installed at the permeate outlet of the last reverse osmosis membrane shell, and the change of the product water flow rate with time is recorded when the system is running.

[0028] Three valves are installed in the reverse osmosis membrane unit: water inlet three-way valve, water outlet three-way valve and two-way regulating va...

Embodiment 2

[0039] In this embodiment, the amount of antiscalant in Example 1 is changed for testing. The system configuration is shown in Figure 1.

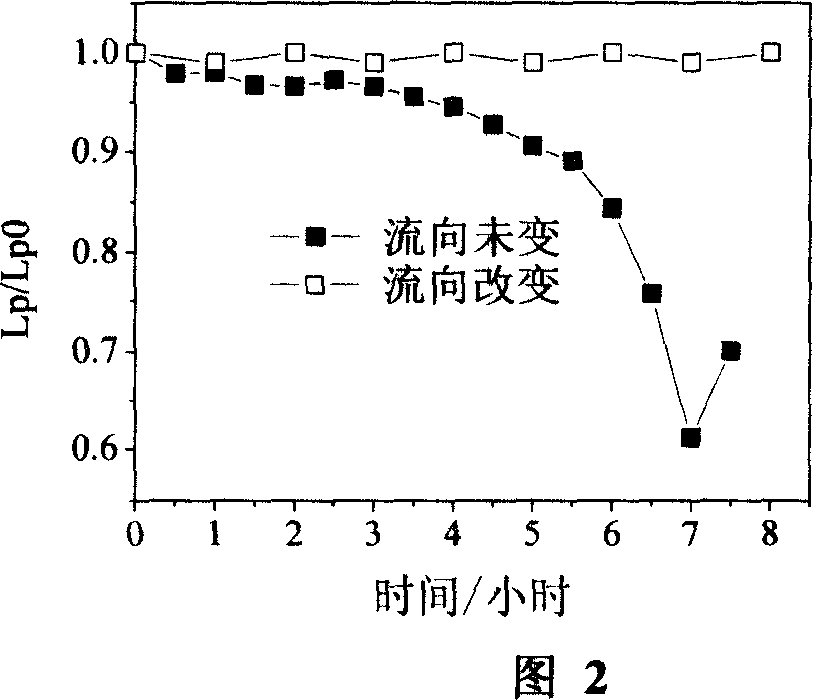

[0040] Weigh 61.47gCaCl 2 , 43.3g NaHCO 3 , 10.58 g NaNO 3 , 5.05gMgSO 4 Prepare 106L solution, and adjust solution pH to 7.6 with NaOH, the LSI index (Langelier Langelier saturation index) of solution is 1.19, and this solution is to CaCO 3 is supersaturated. The scale inhibition experiment was carried out with commercial scale inhibitor LB0100, and the dosage of scale inhibitor was 3mg / L.

[0041] Close the two-way regulating valve, adjust the outlet three-way valve to make the raw water flow upward, and then adjust the water inlet three-way valve to make the raw water flow positive and upward. Start the high-pressure pump, run the system, adjust the bypass valve and regulating valve, so that the inlet pressure is 15 bar, and the concentrate flow rate is 200L / h. At this time, the raw water flows in the forward direction in the six ...

Embodiment 3

[0048] In this embodiment, the flow rate of the concentrated solution in Embodiment 2 is changed for testing. The system configuration is shown in Figure 1.

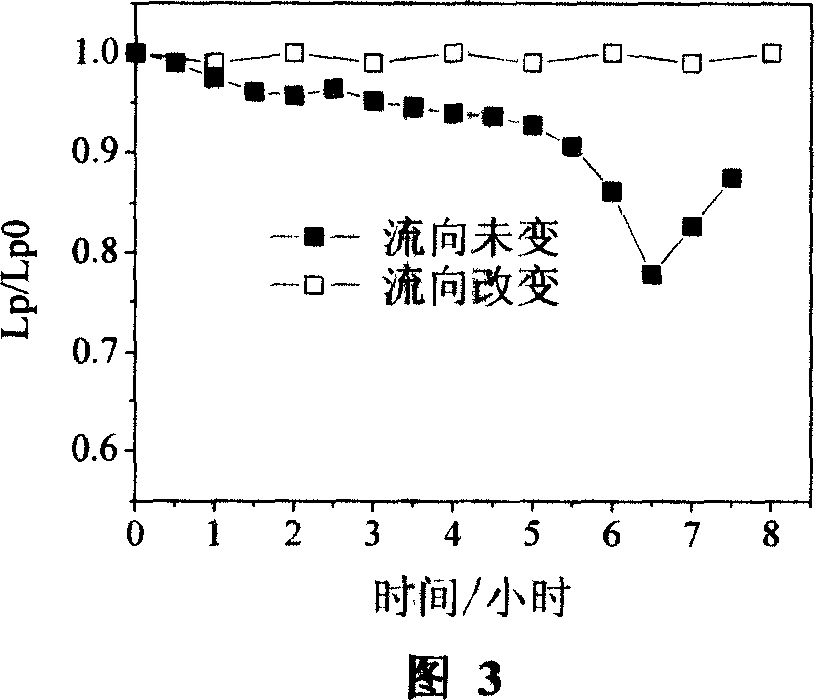

[0049] Weigh 61.47gCaCl 2 , 43.3g NaHCO 3 , 10.58 g NaNO 3 , 5.05gMgSO 4 Prepare 106L solution, and adjust solution pH to 7.6 with NaOH, the LSI index (Langelier Langelier saturation index) of solution is 1.19, and this solution is to CaCO 3 is supersaturated. The scale inhibition experiment was carried out with commercial scale inhibitor LB0100, and the dosage of scale inhibitor was 3mg / L.

[0050] Close the two-way regulating valve, adjust the outlet three-way valve to make the raw water flow upward, and then adjust the water inlet three-way valve to make the raw water flow positive and upward. Start the high-pressure pump, run the system, adjust the bypass valve and regulating valve, so that the inlet pressure is 15 bar, and the concentrate flow rate is 300L / h. At this time, the raw water flows in the forward d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com