Self-propelled garlic digging harvester

A harvester and self-propelled technology, which is applied to digging harvesters, harvesters, excavators, etc., can solve the problem of no garlic harvesting function, and achieve the effect of improving labor productivity and reducing labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0010] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

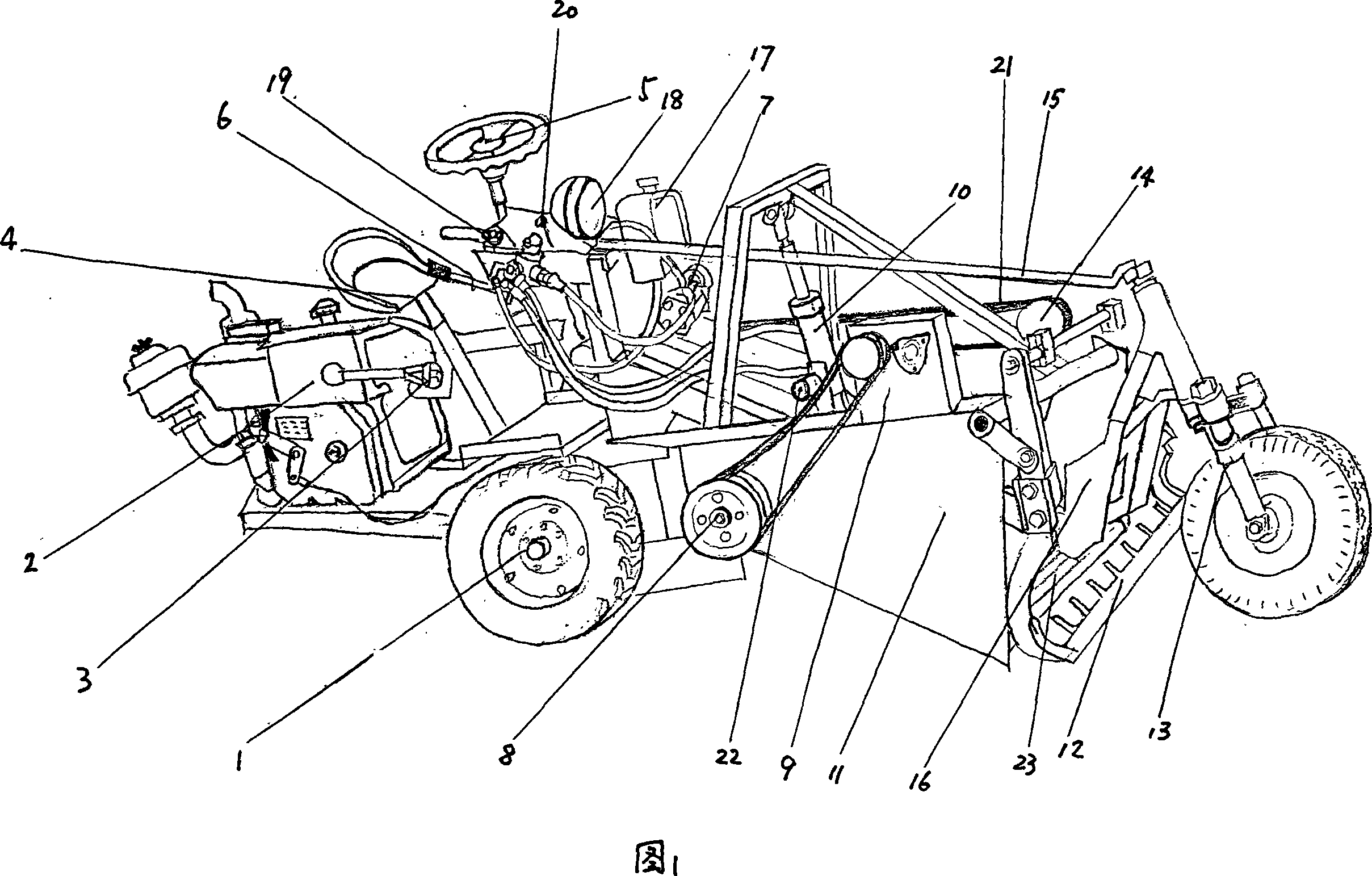

[0011] As shown in Figure 1, the garlic harvester includes an engine, a transmission system, a chassis, a steering machine, and a movable cutter head. The transmission system obtains motion and power from the engine 2, and then divides into three branches, one of which drives the garlic harvester. Move, its moving direction is controlled by the steering machine 5 driving the direction pull rod 15 to drive the toggle lever to control the front steering wheel assembly 13; a branch road drives the movable cutter head 12 through the transmission V-belt 21, eccentric bearing 14 and connecting rod and lever mechanism. Digging movement; a branch road drives the conveying chain and the sieve bar 23 through the transmission V-belt 21, the gearbox assembly 9, the driven shaft of the sieve bar and the belt pulley 8 to perform soil sieving and con...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com