Static spinning equipment of Nano fiber

A nanofiber and electrospinning technology, applied in fiber processing, textile and papermaking, filament/thread forming, etc., can solve the problems of easy blockage of spinneret holes and low production efficiency, and achieve large-scale production and production efficiency. high effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

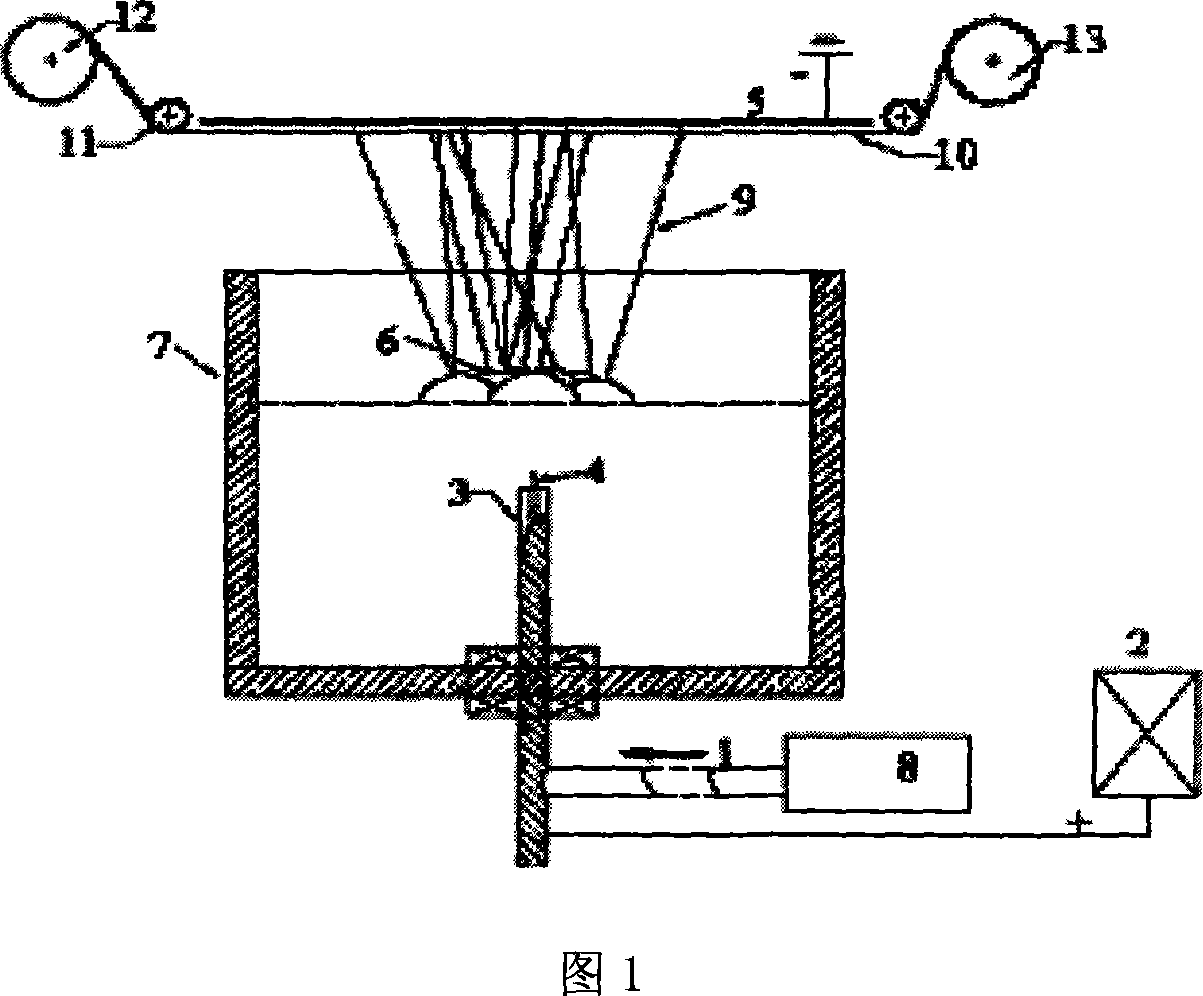

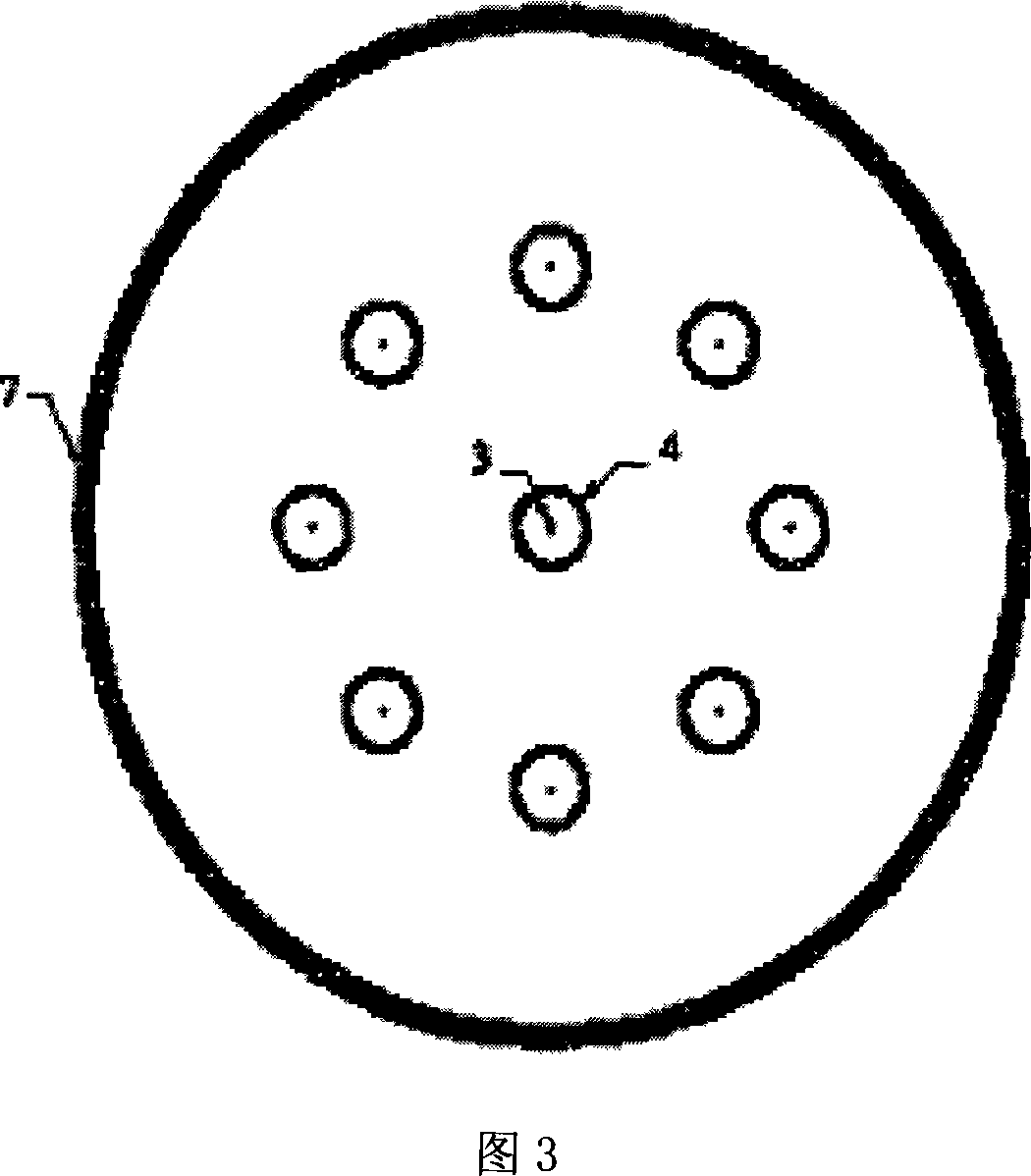

[0022] The present invention provides a bottom-up nanofiber electrospinning device, comprising a tip metal electrode 4, a high-voltage electrostatic generator 2, a metal plate receiving electrode 5, a receiving curtain 10, a cylindrical liquid storage tank 7 with an open top, and Air pump 8, air pump 8 links to each other with the hollow tube that is made by insulating material, and hollow tube leads to jet hole 3, and the amount of liquid added in the liquid storage tank 7 should be higher than the top of metal electrode 4, and the bottom surface of liquid storage tank 7 is equipped with The jet hole 3 connected with the air pump 8, as shown in Figure 3, has 8 jet holes 3 arranged in concentric circles, the tip metal electrode 4 is arranged at the center of the jet hole 3, and the top of the metal needle of the tip metal electrode 4 slightly protrudes The top 1-2 mm of the jet hole, the tip metal electrode 4 is connected with the high-voltage electrostatic generator 2 near the...

Embodiment 2

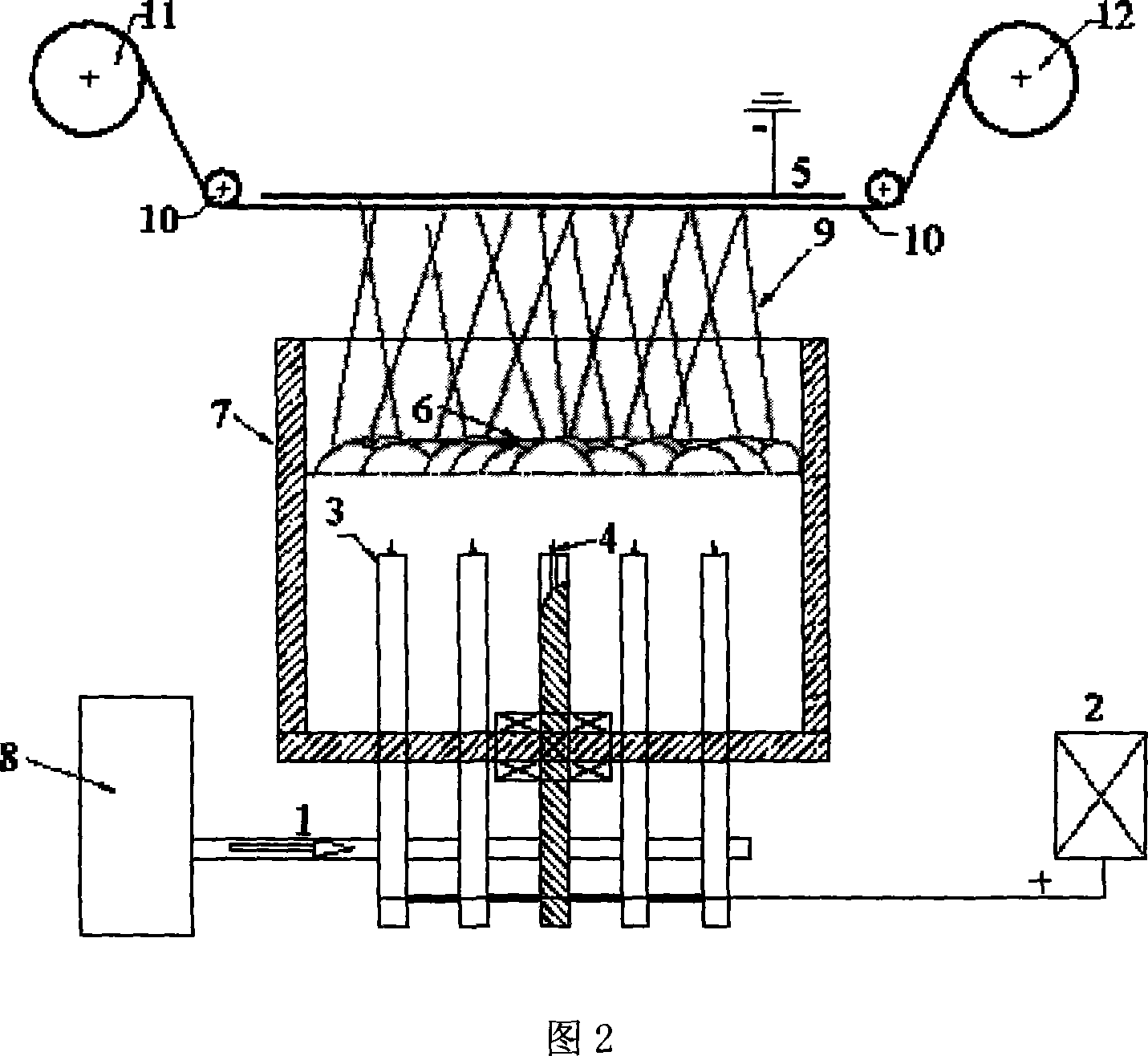

[0024] The present invention provides a bottom-up nanofiber electrospinning device, comprising a tip metal electrode 4, a high-voltage electrostatic generator 2, a metal sawtooth receiving electrode 5, a receiving curtain 10, a cylindrical liquid storage tank 7 with an open top, and The air pump 8, the air pump 8 is connected with the hollow tube made of insulating material, the hollow tube leads to the air jet hole 3, and the bottom surface of the liquid storage tank 7 is equipped with the air jet hole 3 connected with the air pump 8, as shown in Figure 4, there are 9 air jet holes in total The fumaroles 3 are arranged in a matrix, and the tip metal electrode 4 is arranged at the center of the fumarole 3. The top of the metal needle of the tip metal electrode 4 slightly protrudes from the top of the fumarole by 1-2 mm, and the tip metal electrode 4 is on the bottom of the liquid storage pool 7. Nearby is connected with high-voltage electrostatic generator 2. The metal receivi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com