Ink control apparatus, printer, and printing method

A control device, ink technology, applied in printing presses, general parts of printing machinery, printing, etc., can solve complex problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] Hereinafter, exemplary embodiments according to the present invention will be explained in detail with reference to the accompanying drawings. The present invention is not limited to the following examples.

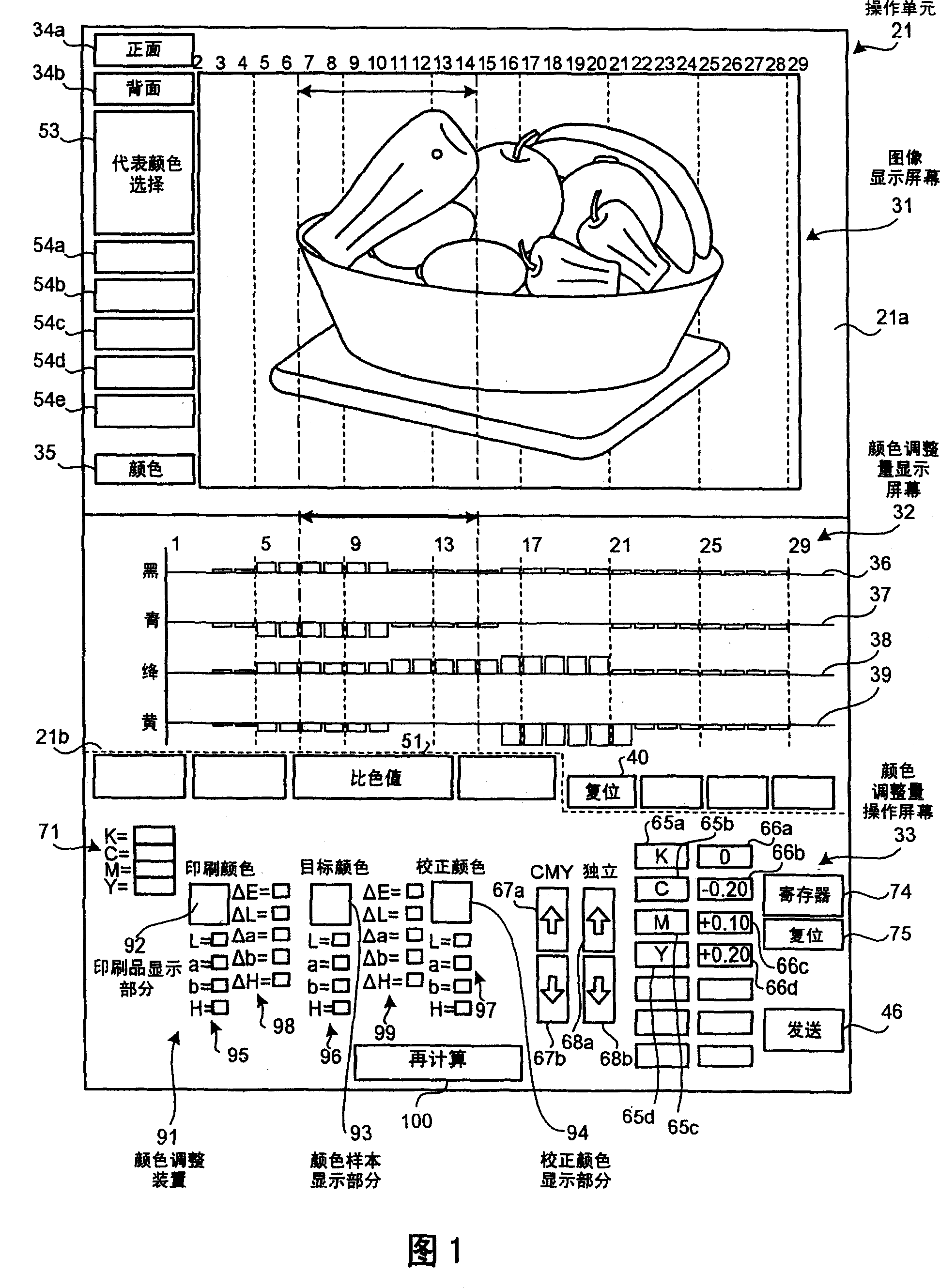

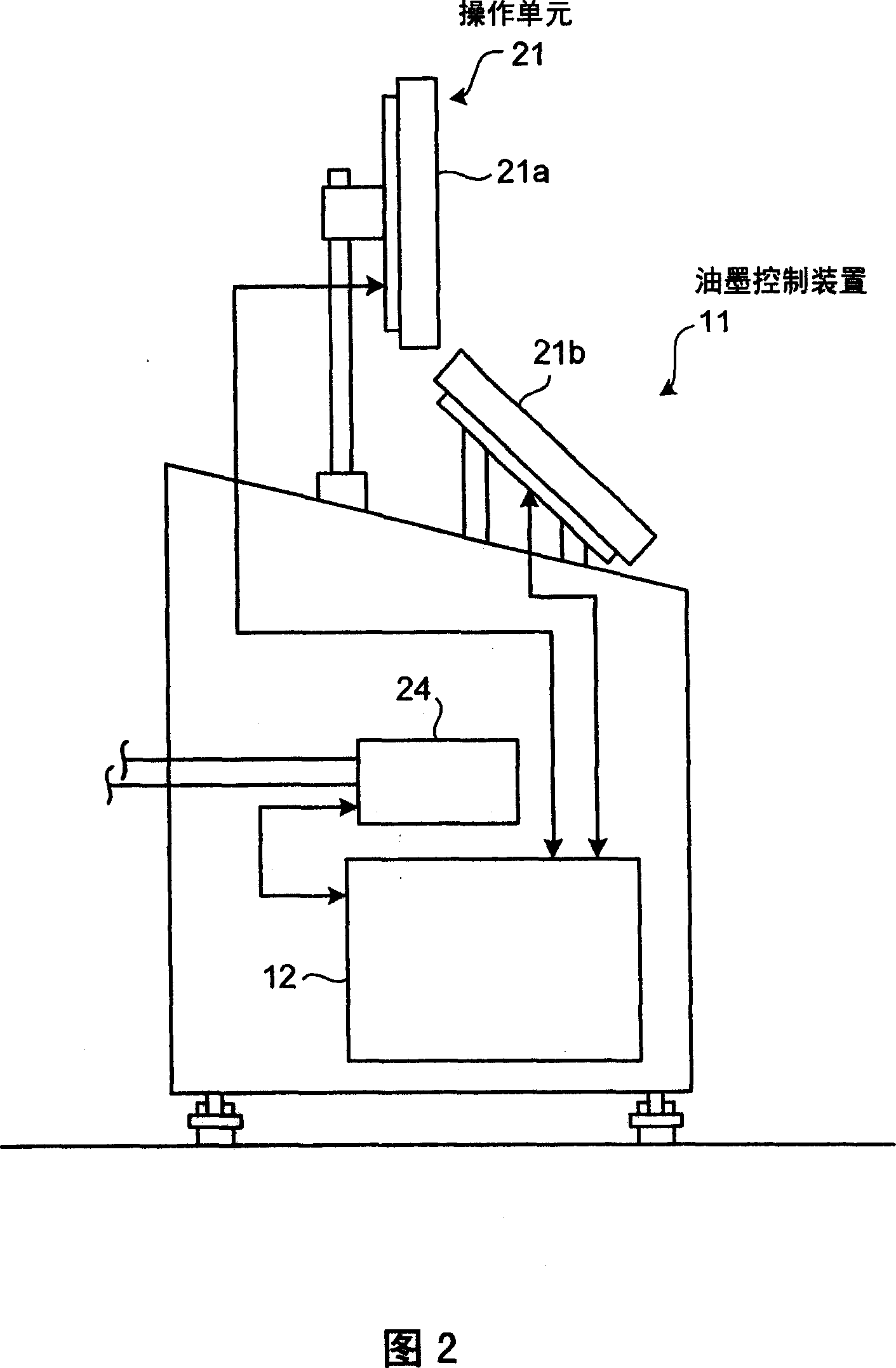

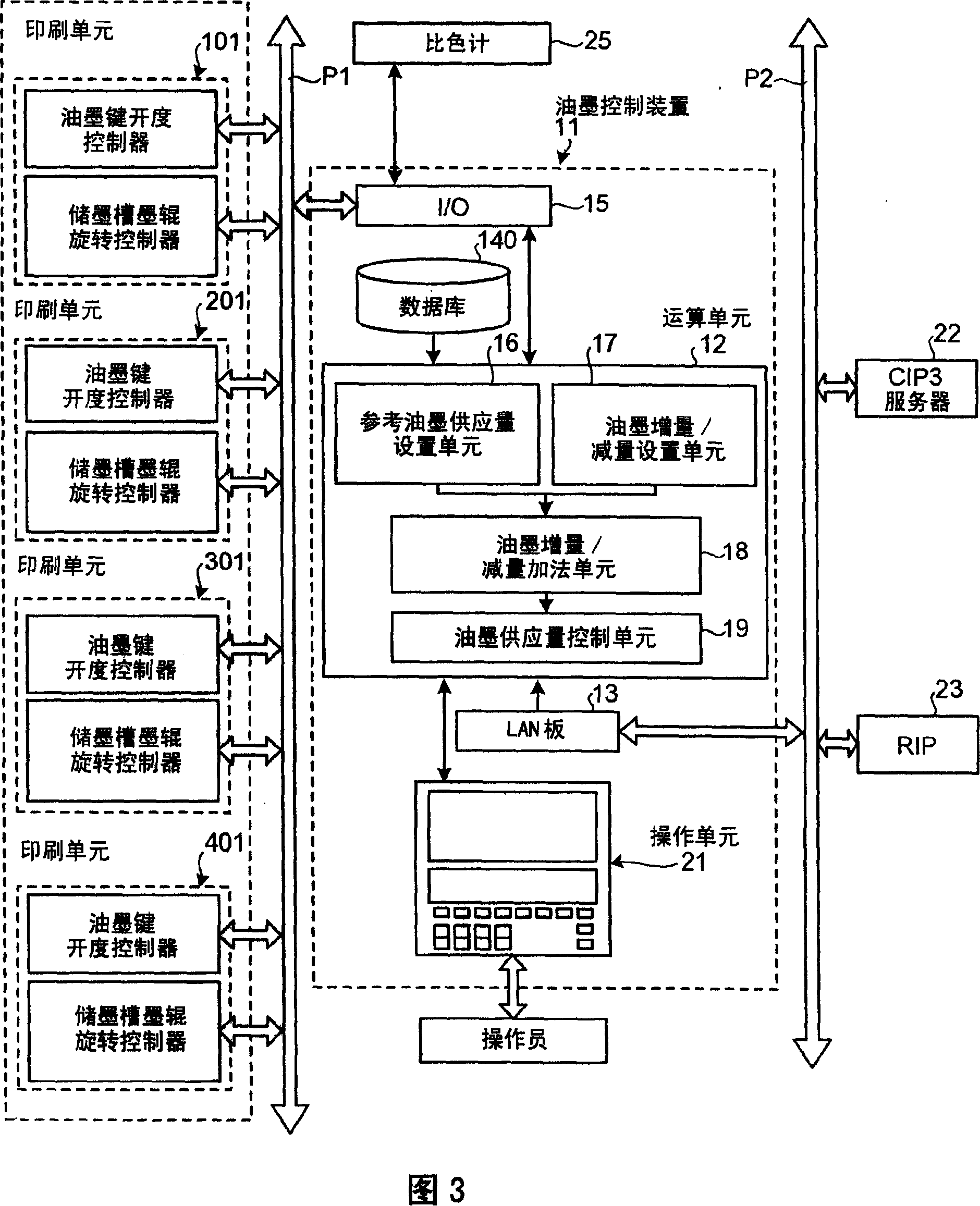

[0029] 1 is a schematic diagram of an operation unit of an ink control device in a printing press according to a first embodiment of the present invention. Fig. 2 is an external view of the ink control device in the printing press according to the first embodiment. Fig. 3 is a block diagram of the ink control device in the printing press according to the first embodiment. Fig. 4 is a processing block diagram of ink supply amount control performed by the ink control device in the printing press according to the first embodiment. Fig. 5 is a process block diagram of ink supply amount control for each ink keypad by the ink control means in the printing press according to the first embodiment. FIG. 6 is a graph of changes in ink key opening degrees with respect to i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com