Knock sensor

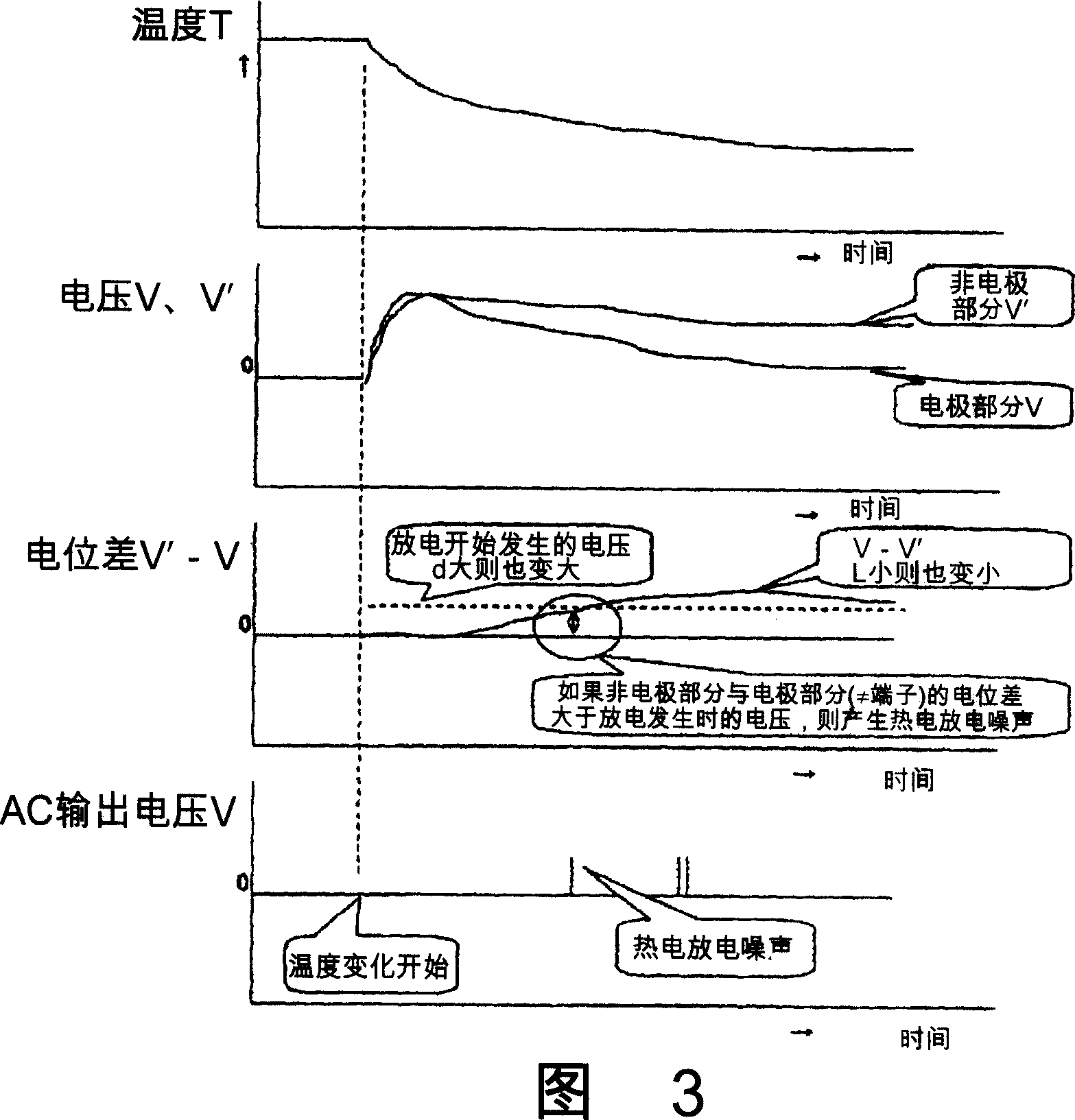

A technology of deflagration sensor and piezoelectric element, which is applied in the field of deflagration sensor, can solve the problems of wrong judgment of deflagration signal and superimposition, and achieve the effect of changing output sensitivity and stabilizing output

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0040] Embodiment 1

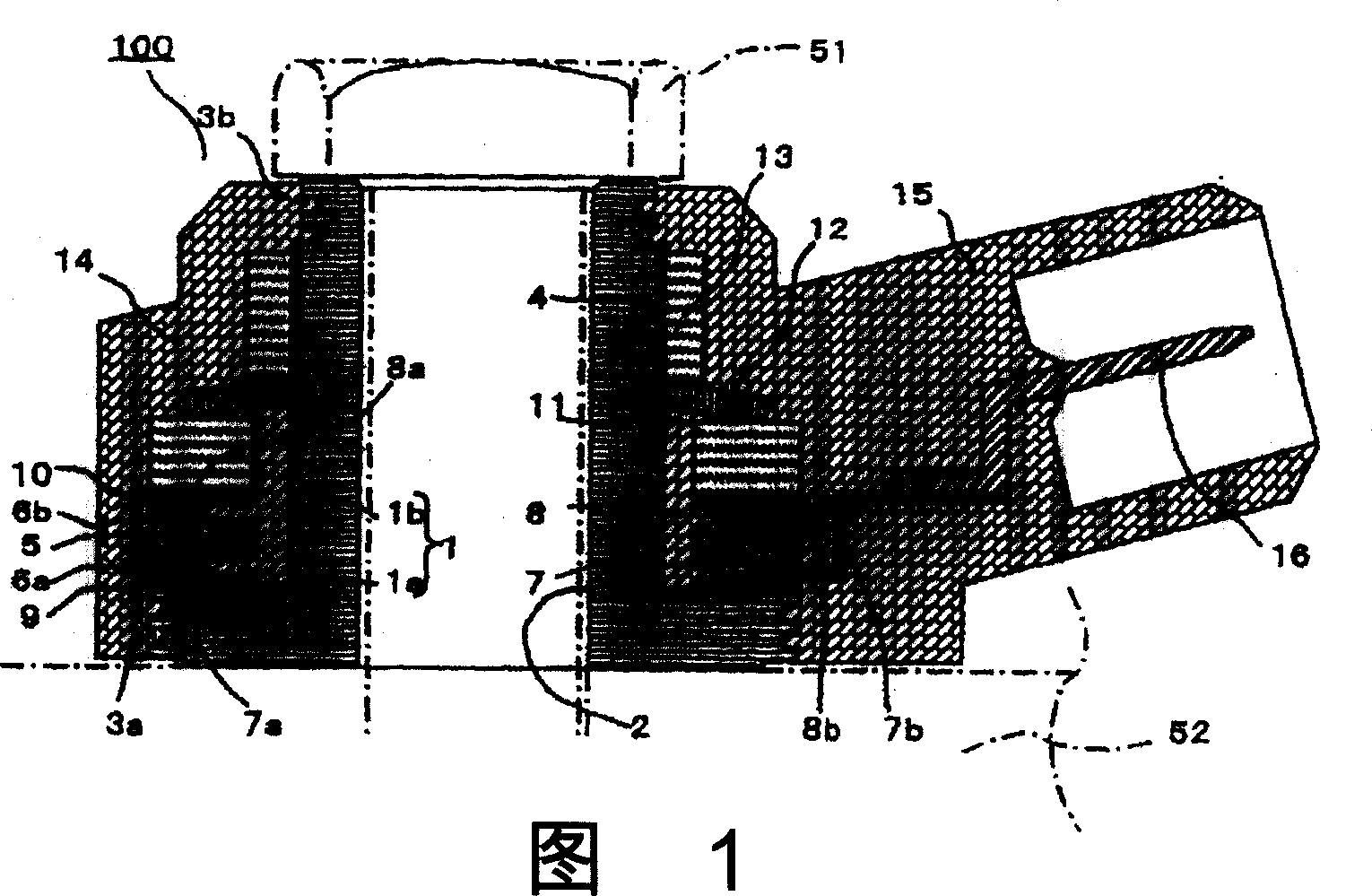

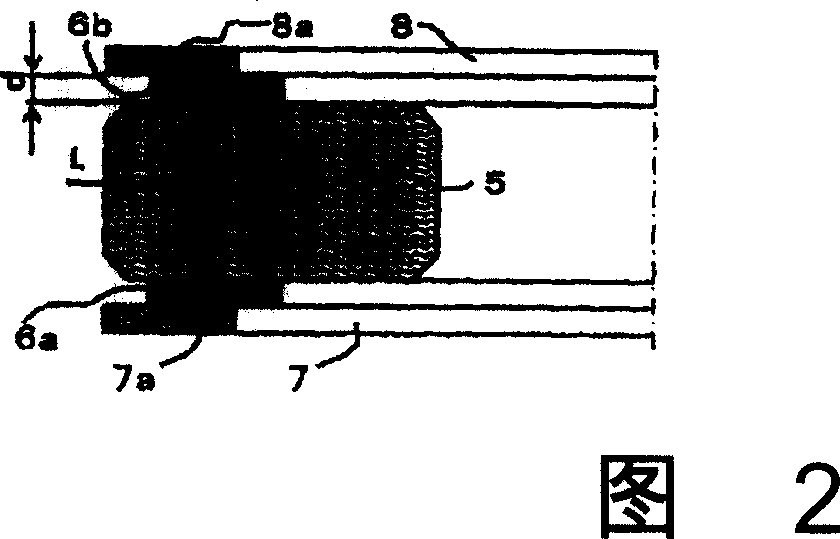

[0041] Fig. 1 is a longitudinal sectional view of a knock sensor according to Embodiment 1 of the present invention, and Fig. 2 is an enlarged sectional view illustrating a main part of the knock sensor according to Embodiment 1 of the present invention.

[0042] In Fig. 1 and Fig. 2, the base 1 is made of metal materials such as SWCH (steel for cold rolling), and has an annular flange portion 1a and a cylindrical portion 1b extending axially from the flange portion 1a. A through hole 2 is formed axially through the flange portion 1a and the cylindrical portion 1b. Then, a plurality of engagement grooves 3a, 3b are respectively formed on the outer peripheral surface of the flange portion 1a and the outer peripheral surface of the front end portion of the cylindrical portion 1b. Furthermore, the male screw portion 4 is engraved on a predetermined area of the front end side outer peripheral surface of the cylindrical portion 1b.

[0043] The piezoelectr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com