Solid lubrication precision wave filtering driving device

A technology of solid lubrication and driving devices, which is applied in the directions of transmission devices, mechanical equipment, vacuum evaporation coating, etc., can solve the problems of high manufacturing and processing requirements, poor workmanship, and large additional dynamic load, etc. Low cost, the effect of preventing axial movement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

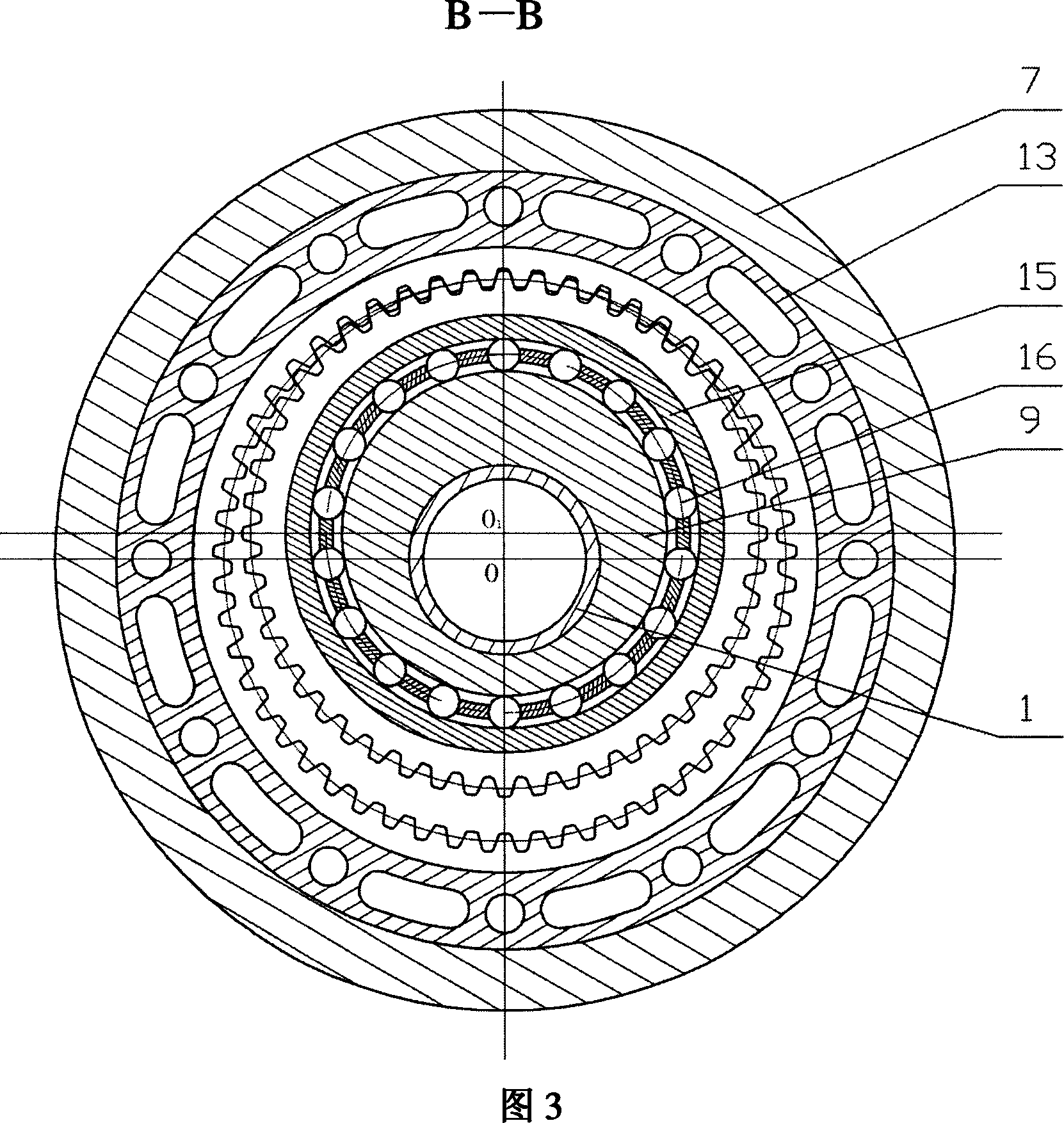

[0027] As shown in Figure 1, the number of teeth of the left and right gears of the input duplex gear 15 are respectively Zc=45 and Zd=48, and the number of teeth of the fixed gear 13 and the output gear 17 are respectively Zb=53 and Za=50. Input the left gear of double gear 15 and output gear 17 few tooth differences and the right gear of input double gear 15 and fixed gear 13 few teeth differences equal, few teeth differences are all 5.

[0028] Installation of solid lubricated precision filter driving device: the reducer and the servo motor are respectively installed from the left and right sides to the middle, the rotating shaft 1 of the servo motor is directly connected with the eccentric cam 9 of the reducer, the bearing 8 is installed on the rotating shaft 1, and the fixed gear 13 passes through A group of screws 11 on the circumference are connected with the casing 7, and the left end of the output gear 17 is connected with the output shaft 23 through a group of scre...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com