Device and method for preparing calibrating gas

A standard gas and gas sampling technology, applied in mixing methods, chemical instruments and methods, gas and gas/steam mixing, etc., can solve the problems of single concentration of gas samples, accuracy affected by vacuum degree, harsh conditions, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0057] Embodiment 1: The gas storage bottle is filled with solvent gas by the method of water drainage and gas collection

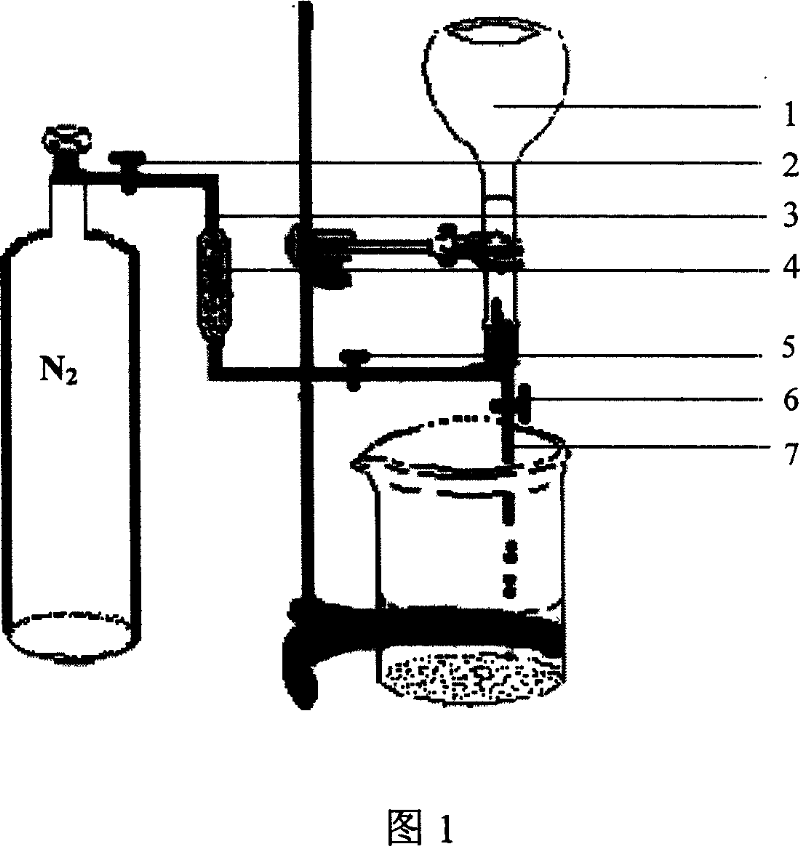

[0058] As shown in Figure 1, the gas cylinder (1) is filled with water, the bottle mouth is tightly closed with a rubber stopper with conduit A (3) and conduit B (7), and valve A (5) and valve B (6) are closed , and then fix it upside down on the iron stand, connect the inlet end of conduit A (3) to the nitrogen cylinder, slowly open the pressure reducing valve (2) on the cylinder, and simultaneously open valve A (5) and valve B (6), so that Fill the entire pipeline with nitrogen gas and enter the gas storage bottle (1), drain the liquid slowly, after the liquid flows out, blow off the pipeline slowly with nitrogen gas, and gradually reduce the pressure to the catheter B (7) inserted in the beaker When the last bubble is discharged, quickly close valve A (5) and valve B (6), seal the bottle mouth, and set aside.

Embodiment 2

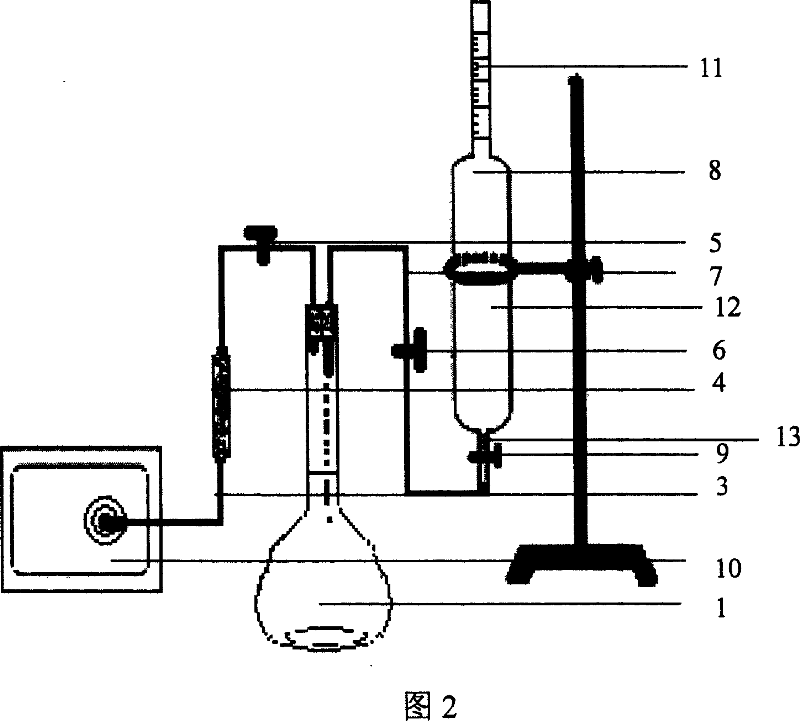

[0060] As shown in Figure 2, in the standard gas preparation device, the quantitative bottle (8) is connected with the gas storage cylinder (1) through a conduit B (7) provided with a valve B (6), and the gas sampling bag (10) is connected with the gas storage cylinder (1) connected by the conduit A (3) that is provided with valve A (5); the upper scale tube (11) and the lower scale tube (13) in the quantitative bottle (8) are connected as a whole by the base tube (12), and the lower scale The pipe (13) is provided with a valve C (9); a gas drying pipe (4) is provided between the gas sampling bag (10) and the gas cylinder (1).

Embodiment 3

[0062] The nitrogen collected in the gas cylinder (1) in Example 1 was used. As shown in Figure 2, inject saturated salt water into the gas quantitative bottle (8), adjust valve C (9) to fill the pipeline B (7) with saturated salt water, and add saturated salt dropwise to the gas quantitative bottle (8) Water to 498.0ml; open valve C (9) and valve B (6) of the gas quantitative bottle, saturated saline enters the gas storage bottle (1), and discharges the gas in the gas storage bottle (1) into the gas sampling in the bag (10) (the gas sampling bag needs to be evacuated first and rinsed with nitrogen for 3 times). When the saturated saline liquid level reaches the zero mark line of the lower scale tube (13) of the quantitative bottle (8), close the valve C (9). The exact volume between the scale marks is 498.0ml; while charging nitrogen into the gas sampling bag (10), accurately absorb 2.00ml of methane gas with an airtight syringe, then the final concentration of methane gas i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com