Test methods for static load detection

A test method and static load detection technology, which is applied in the test of basic structure, construction, basic structure engineering, etc., can solve problems such as waste, instability, loading and unloading inconvenience, and achieve convenient assembly and disassembly, save time and avoid Troublesome and time-consuming, easy to uninstall and easy to operate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] Embodiments of the present invention will be described below in conjunction with the accompanying drawings.

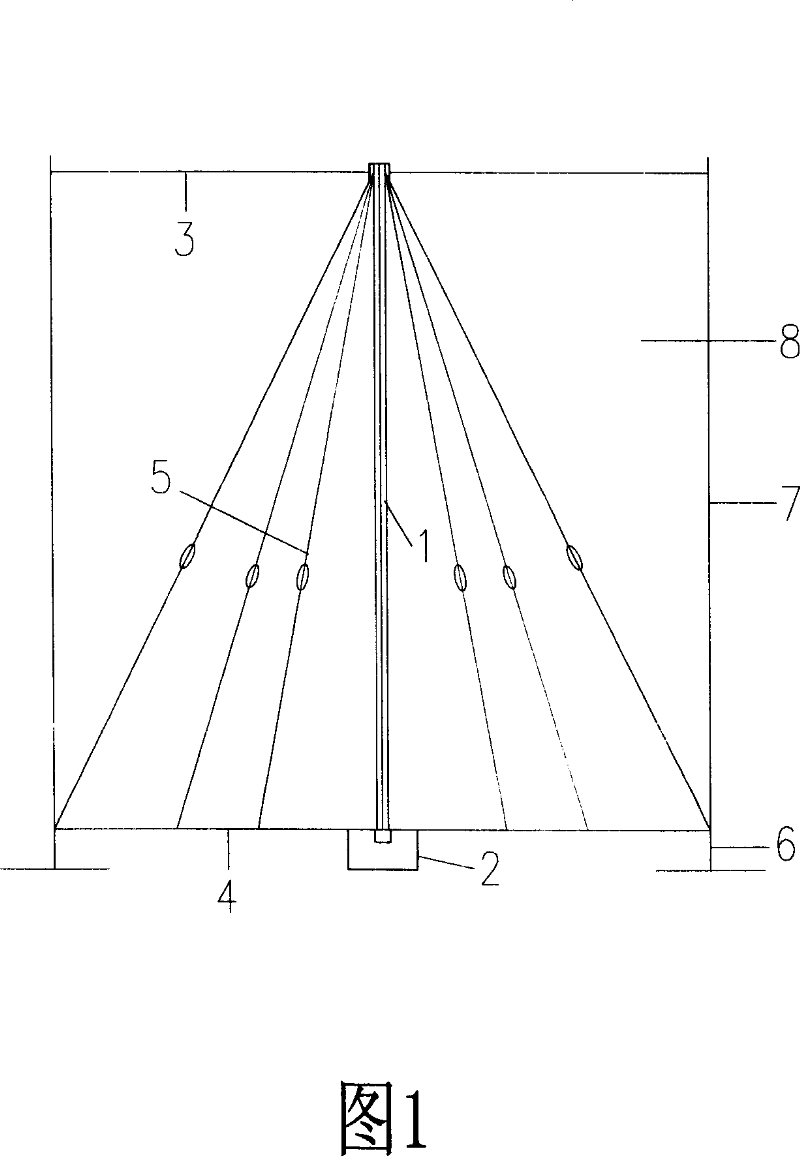

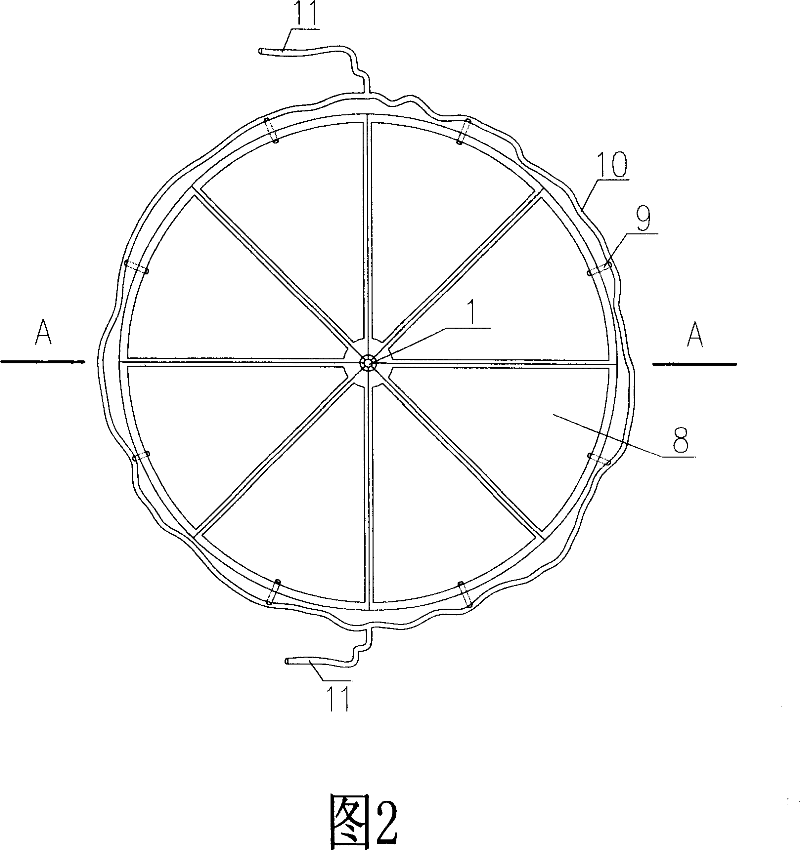

[0026] Figure 1 is a cross-sectional view of the static load detection test device, in which the center load-bearing rod 1 is supported on the center foot 2, the jack and the testing instrument are placed in the center foot 2, and there are eight upper pull rods 3 and eight lower pull rods 4, each of which is up and down. Correspondingly, one end of the lower rod 4 is flexibly connected to the central load-bearing rod 1, and the other end is flexibly connected to the peripheral leg 6, a baffle 7 is vertically set up between the peripheral legs, and one end of the upper pull rod 3 is connected to the central load-bearing rod 1, the other end is connected to the peripheral baffle 7 top. On the plane formed between the eight lower rods 4, a plurality of cross bars are arranged between the lower rods 4 and connected with the lower rods by pins, and the liquid contai...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com