Enclosuring-hoop type curled-edge like enclosure, its sealing, clamping and making method

A technology of closure and closure hoop, applied in the directions of sealing, clamping device, closing, etc., can solve the problem of not being able to reliably clamp the top cover of the barrel

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

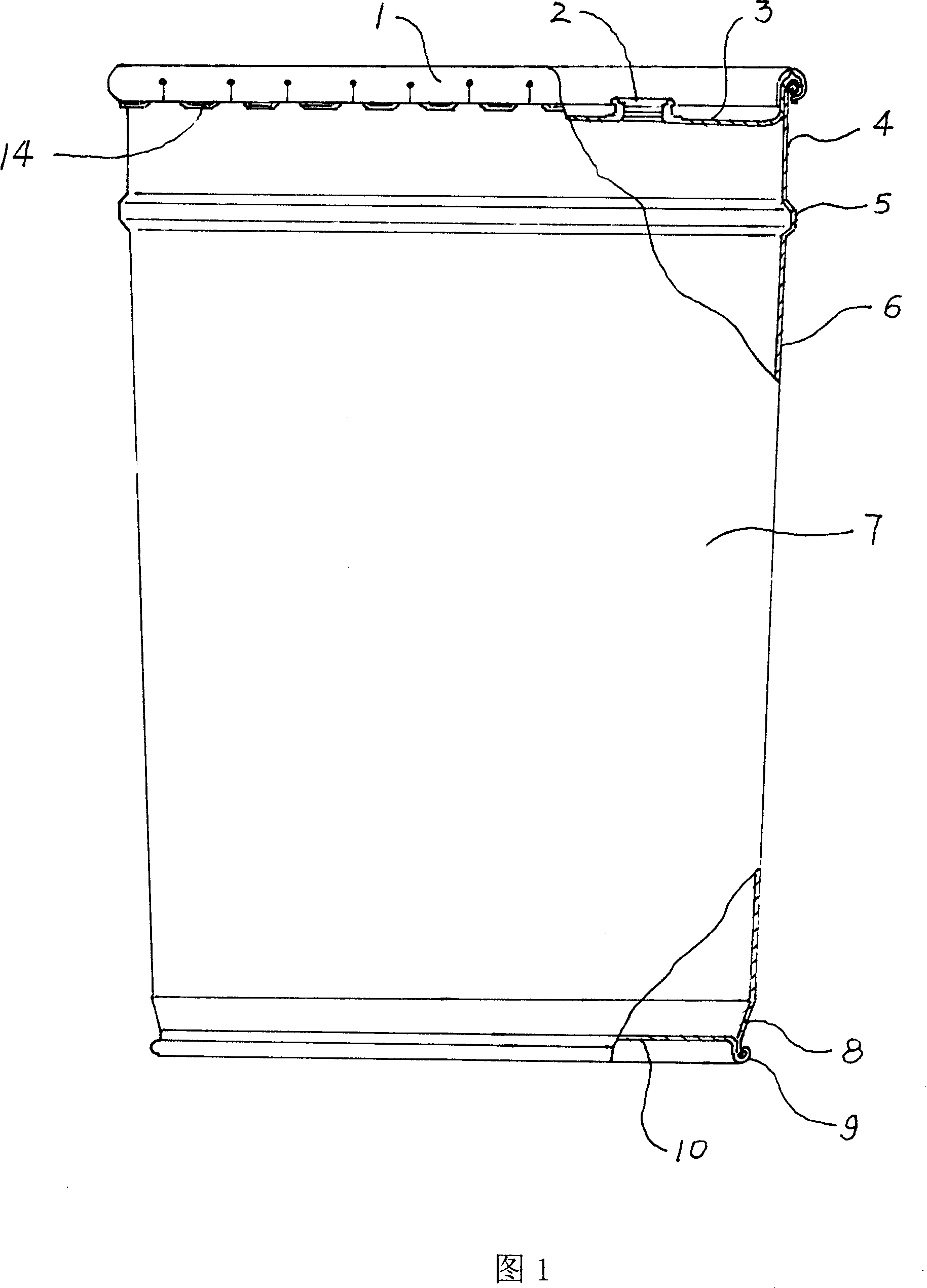

[0020] Fig. 1 is 200 liters of closed conical steel barrels 7 of detachable barrel top cover. It is equipped with an integral ring-shaped closed hoop-type crimping type closure. The closed conical steel drum is exactly the same as the closed cylindrical steel drum in use, only when the empty drum is transported and the old drum is cleaned and repaired. Just need to insert dismantling port 14 with tool, rotate counterclockwise, open closing device and take off barrel top cover 3. It is transported and cleaned and repaired as a full-open conical steel drum. The functions and structures of its cylindrical barrel body 4, reinforcing ribs 5, conical barrel body 6, barrel body lower part 8, barrel bottom 10 and convex edge 9 are all Known ones are no longer described here.

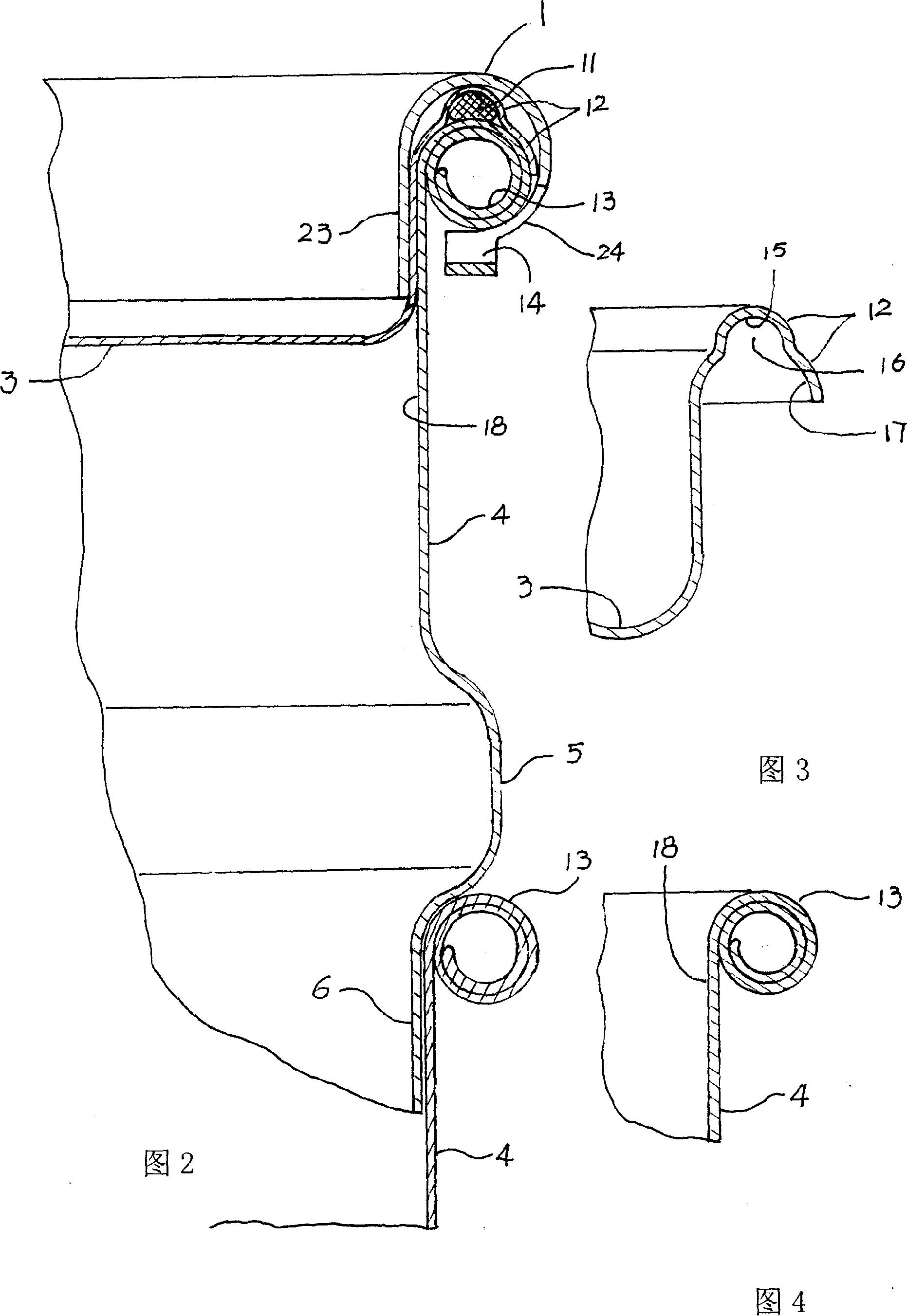

[0021] From Fig. 2 and Fig. 3, it can be seen that the flange 12 of the bucket top cover 3 is composed of two overlapping arc grooves with different radii. Under the clamping effect of the side 23 and the wrap...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com