Cold-hot gas flow high-speed high-low-temperature environmental testing machine

An environmental test, high and low temperature technology, applied in the field of testing machines, can solve the problems of low power required for cooling and heating, achieve the effects of reducing space and area, convenient use and adjustment, and lightening the burden

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] When performing high and low temperature tests or thermal shock tests on tiny electronic and mechanical parts, the power required for cooling and heating is relatively low. It can be used to heat or cool the compressed air first, and then blow the gas directly to the sample after reaching the required temperature, so as to realize two kinds of tests with one testing machine.

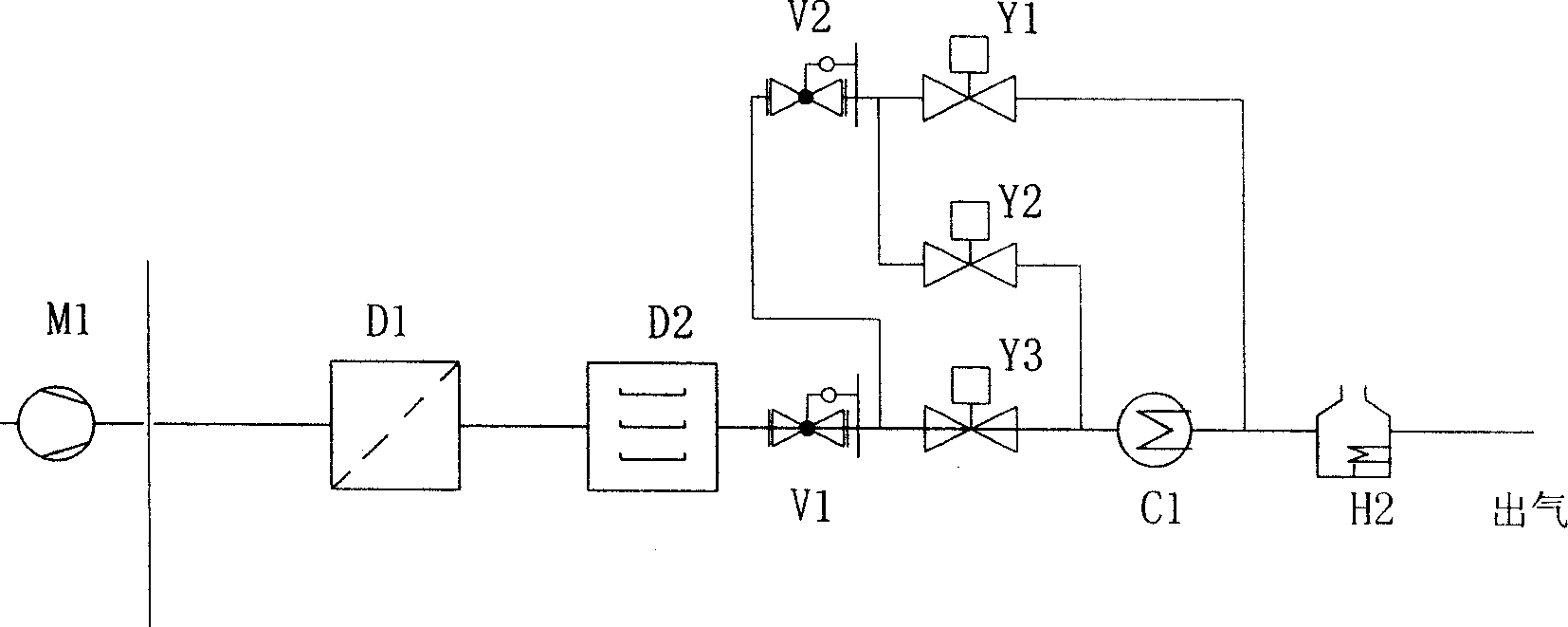

[0016] As shown in the figure, the hot and cold air flow type high-speed high-low temperature environmental testing machine of the present invention comprises oil-removing and water-removing filter D1, heatless regeneration air drier D2 (also can adopt freeze drier. The noise of heatless regeneration air dryer is relatively high large and easy to maintain; the freeze dryer has less noise and more complicated maintenance), the first pressure regulating valve V], the third solenoid valve Y3, the refrigeration heat exchanger C1 and the heater H2, the above components or equipment are serially connecte...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com