Speed transmission

A transmission and controller technology, which is applied to gear transmissions, components with teeth, belts/chains/gears, etc., can solve the problems of high manufacturing cost, complex structure, inability to apply to mining machinery and equipment, etc. Long service life effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

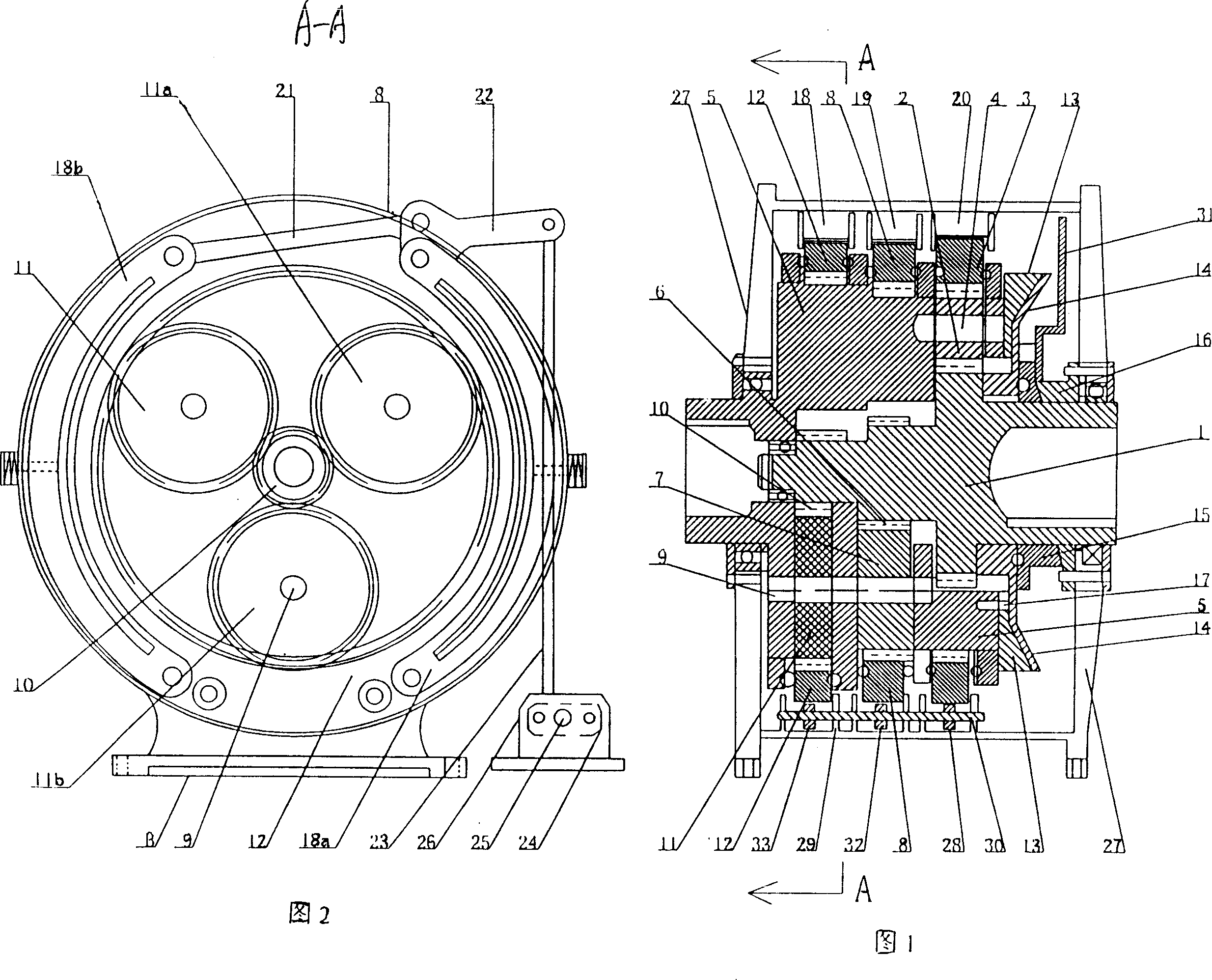

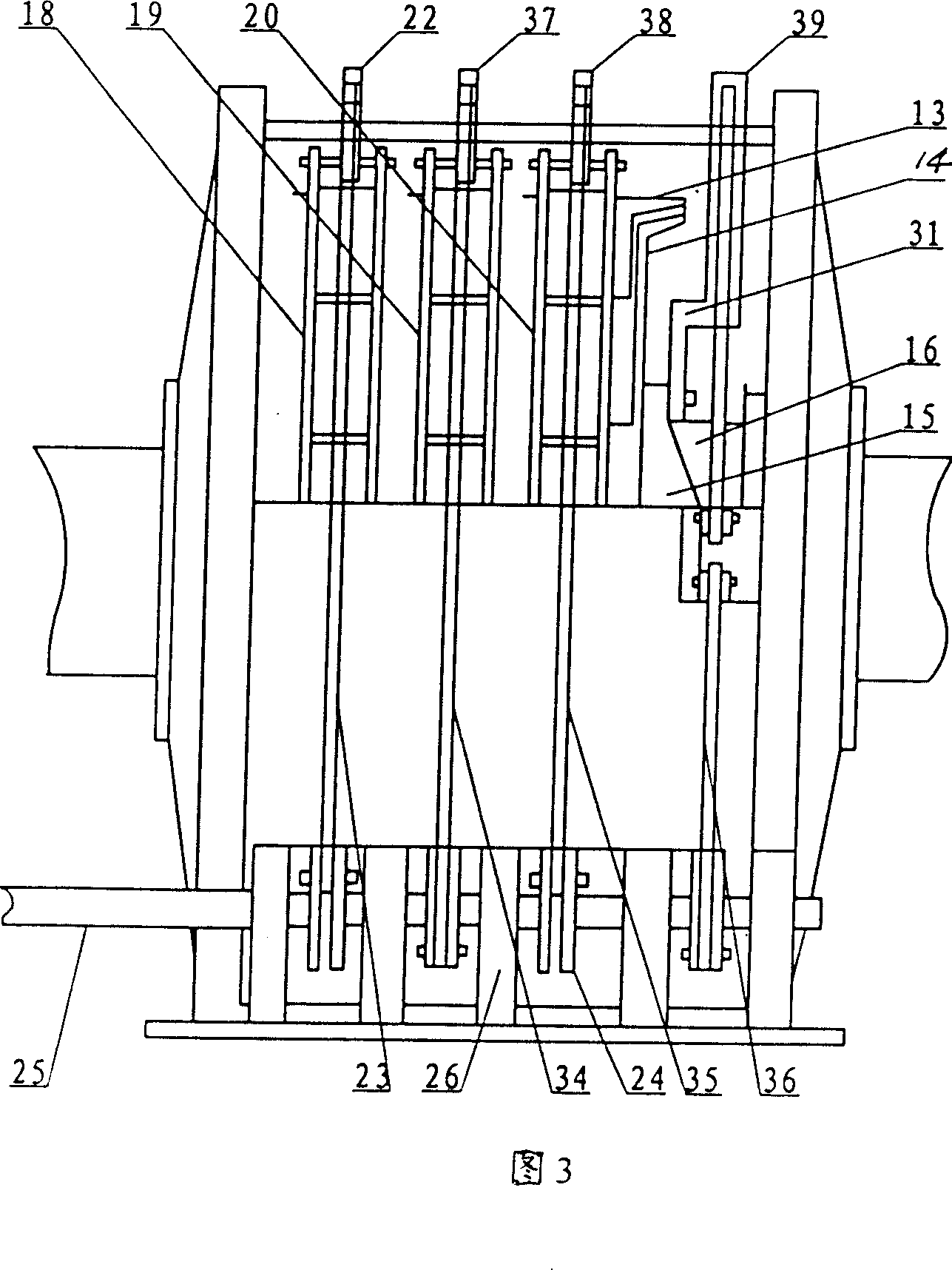

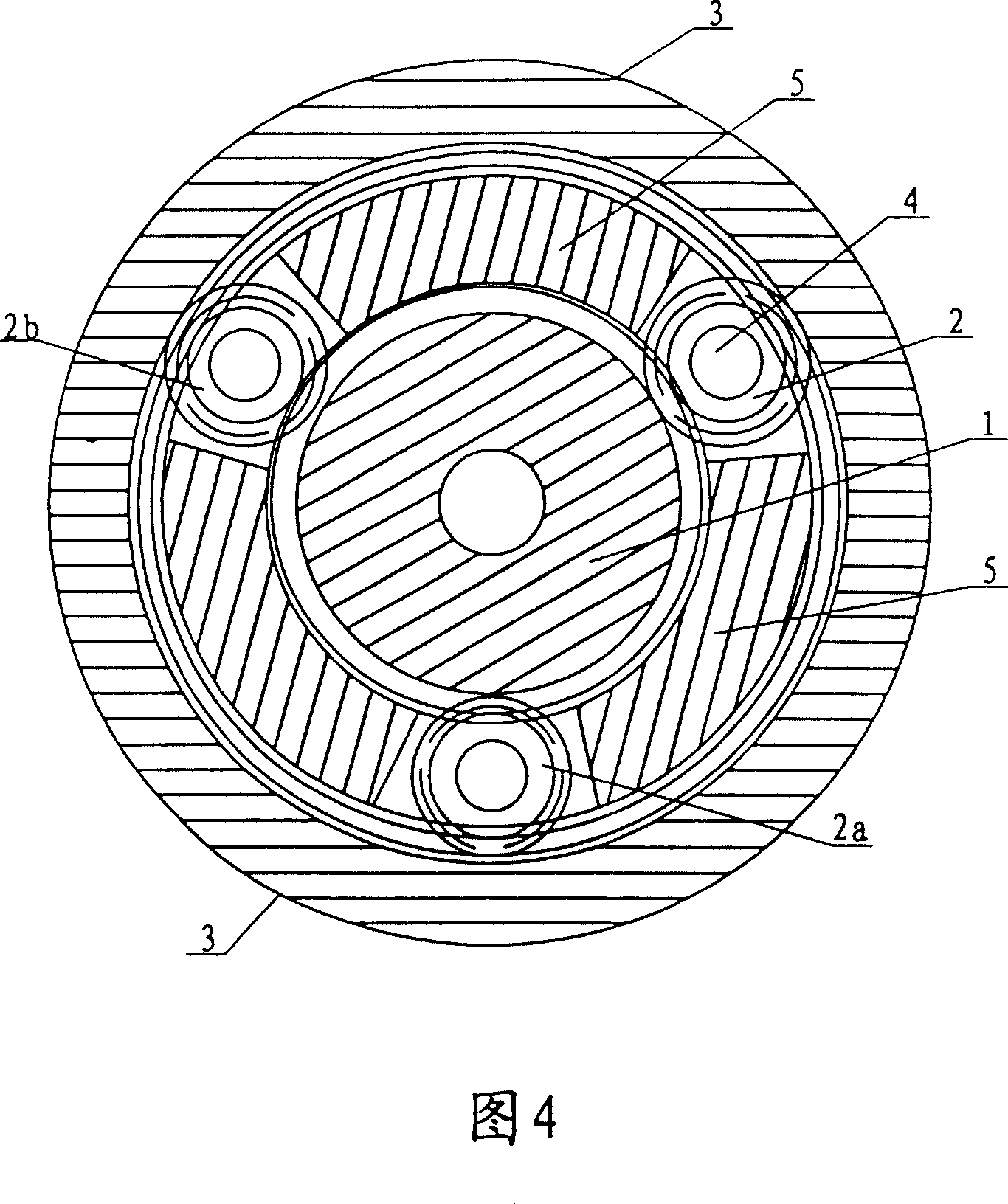

[0012] The present invention will be further described with reference to accompanying drawing:

[0013] 1 in the figure is the sun gear, 27 is the casing, the sun gear 1 is installed at one end of the casing 27, the sun gear 1 is a third-stage wheel, the first-stage teeth of the sun gear 1 mesh with the first-stage planetary gear 2, the first-stage planetary The first-stage internal gear 3 meshes, the first controller 20 is installed outside the first-stage internal gear 3, and the other end of the casing 27 is installed with a star wheel spoke 5, and the star wheel spoke 5 is respectively connected with the second-stage internal gear 8 and the third-stage internal gear 12 meshing, the second-stage tooth 6 of the sun gear 1 meshes with the second-stage planetary gear 7, the second-stage planetary gear 7 meshes with the second-stage ring gear 8, the third-stage tooth 10 of the sun gear 1 meshes with the third-stage planetary gear 11, and the third-stage The planetary gear 11 me...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com