Method for producing breakfast food of slice shaped grain with excellent crisp property

A cereal breakfast and production method technology, applied in the field of breakfast snack food production, can solve the problems of loss of chewing feeling, lower product quality, and turning into paste, etc., and achieve uniform and compact structure, excellent brittleness, Moderate effect of crispness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

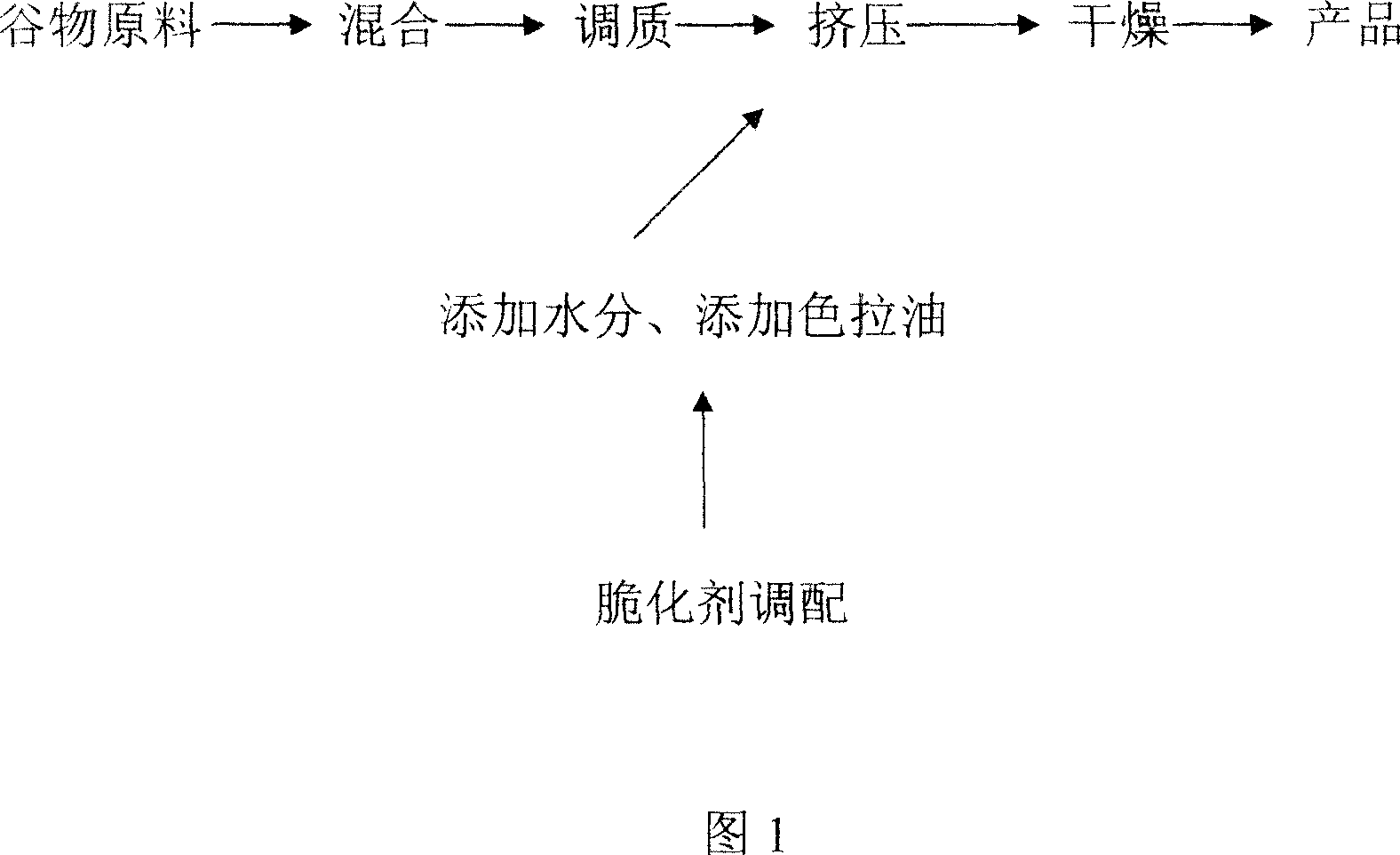

Method used

Image

Examples

Embodiment 1

[0038]Get 700g of corn flour, 70g of wheat flour, and 70g of oat flour, thus calculating that the required added moisture is 120g, the required added salad oil is 40g, and the total amount of raw materials is 1000g. The protein content of the mixed raw material obtained in this proportion is about 7.3%, the fat content is 8%, and the water content is 22.60%. Place cornmeal, wheat flour and oat flour in a high speed mixer and blend until smooth.

[0039] Based on the above calculated total amount of raw materials of 1000 g, the calculated amount of carrageenan (Kappa) to be added is 1.8 g, and the amount of CMC to be added is 0.72 g.

[0040] Dissolve 1.8g of carrageenan (Kappa) and 0.72g of CMC in 80g of water; add 40g of water and mix well; add 40g of salad oil and mix well. Slowly add this mixture to the grain ingredients being mixed in the high speed mixer and mix on high speed.

[0041] Put the mixed raw materials into the twin-screw extruder. The extrusion conditions ar...

Embodiment 2

[0043] Take 700g of corn flour and 140g of oatmeal. From this, the water to be added is 120g, the salad oil to be added is 40g, and the total amount of raw materials is 1000g. The protein content of the mixed raw material obtained in this proportion is about 7.3%, the fat content is 7.8%, and the water content is 23.50%. Place cornmeal, wheat flour and oat flour in a high speed mixer and blend until smooth.

[0044] Based on the above calculated total amount of raw materials of 1000 g, the calculated amount of carrageenan (Kappa) to be added is 1.8 g, and the amount of CMC to be added is 0.72 g.

[0045] Dissolve 1.8g of carrageenan (Kappa) and 0.72g of CMC in 80g of water; add 40g of water and mix well; add 40g of salad oil and mix well. Slowly add this mixture to the grain material that is being mixed in the high-speed mixer and mix at high speed.

[0046] Put the mixed raw materials into the twin-screw extruder. The extrusion conditions are: the temperature of the extrude...

Embodiment 3

[0048] Get 700g of corn flour, 140g of wheat flour, calculate the moisture that needs to add thus be 120g, the salad oil that needs to add is 40g, and raw material total amount is 1000g. The protein content of the mixed raw material obtained in this proportion is about 7.3%, the fat content is 8.2%, and the water content is 21.50%. Place cornmeal, wheat flour and oat flour in a high speed mixer and blend until smooth.

[0049] Based on the above calculated total amount of raw materials of 1000 g, the calculated amount of carrageenan (Kappa) to be added is 1.8 g, and the amount of CMC to be added is 0.72 g.

[0050] Dissolve 1.8g of carrageenan (Kappa) and 0.72g of CMC in 80g of water; add 35g of water and mix well; add 45g of salad oil and mix well. Slowly add this mixture to the grain material that is being mixed in the high-speed mixer and mix at high speed.

[0051] Put the mixed raw materials into the twin-screw extruder. The extrusion conditions are: the temperature of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com