Gate hoist

A hoist and gate technology, applied in water conservancy projects, sea area projects, coastline protection, etc., can solve problems such as long closing time, large flow overflow, power consumption, etc., achieve long service life and avoid direct impact effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

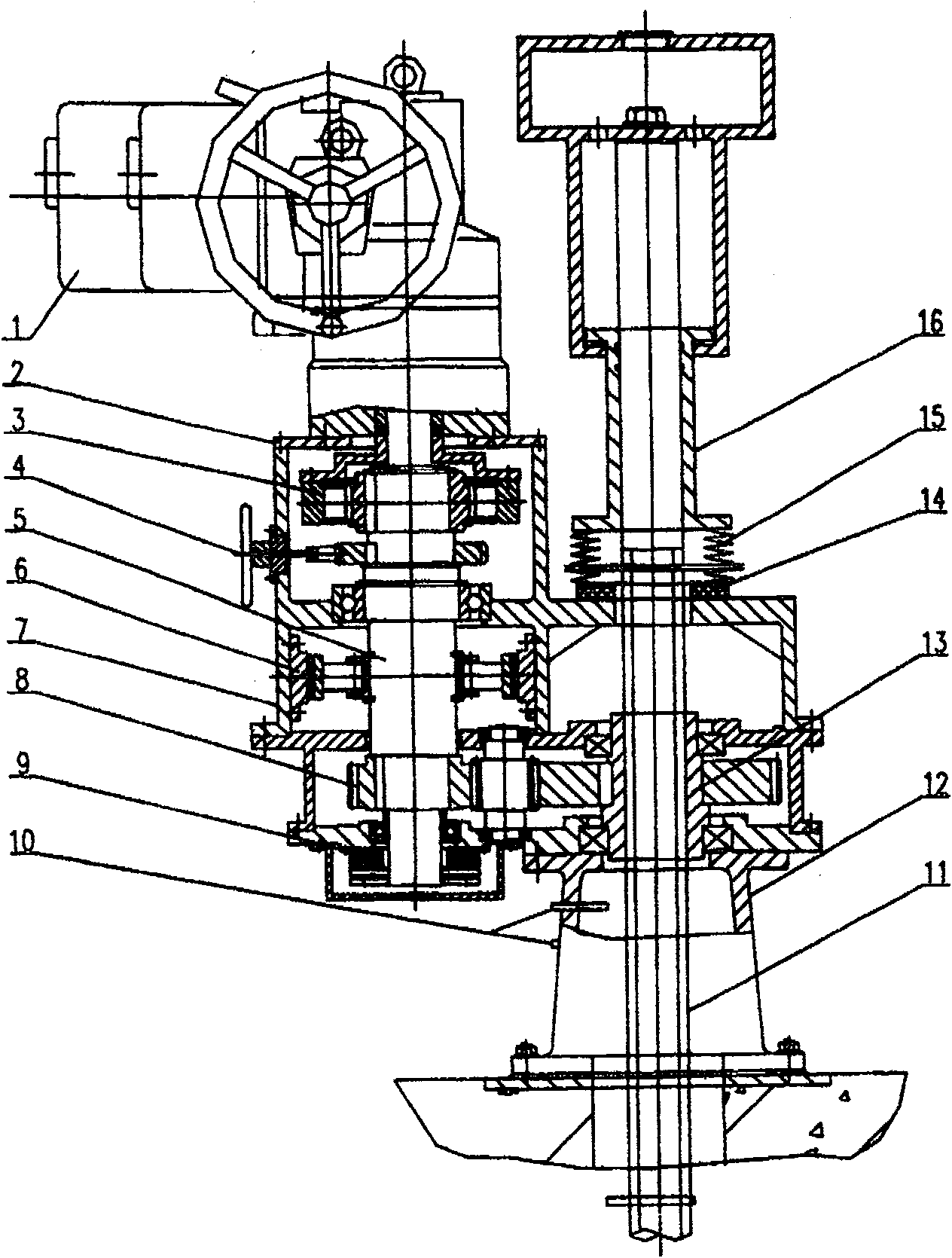

[0017] The frame 12 is connected to the box body 7, and the box body 7 is provided with a transmission cavity and a connecting cavity. A screw 11 is installed in the connecting cavity of the box body 7. The screw screw 11 passes through the upper end surface of the connecting cavity of the connecting box body 7. The top end of the screw screw 11 The buffer cylinder 16 is connected, and a rubber pad 14 and a protective cover 15 are arranged between the buffer cylinder 16 and the machine base 12 . Be provided with the nut 13 that is connected with leading screw in casing 7 connection cavity, nut 13 is connected with casing 7 bearings, and nut 13 key connects a gear.

[0018] The upper end of the transmission cavity of the box body 7 is provided with a drive motor 1, and the drive motor 1 and the box body 7 are connected through a connecting plate 2; the drive shaft of the drive motor 1 extends into the box body 7, and the drive shaft and the transmission shaft 5 pass through a no...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com