Mixed forage for raising milk cow and its preparation method

A dairy cow feed and mixed material technology, which is applied in the field of formula composition of dairy cow concentrate feed, to prevent the invasion of bacteria and viruses, resist the invasion of bacteria and viruses, and improve the quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

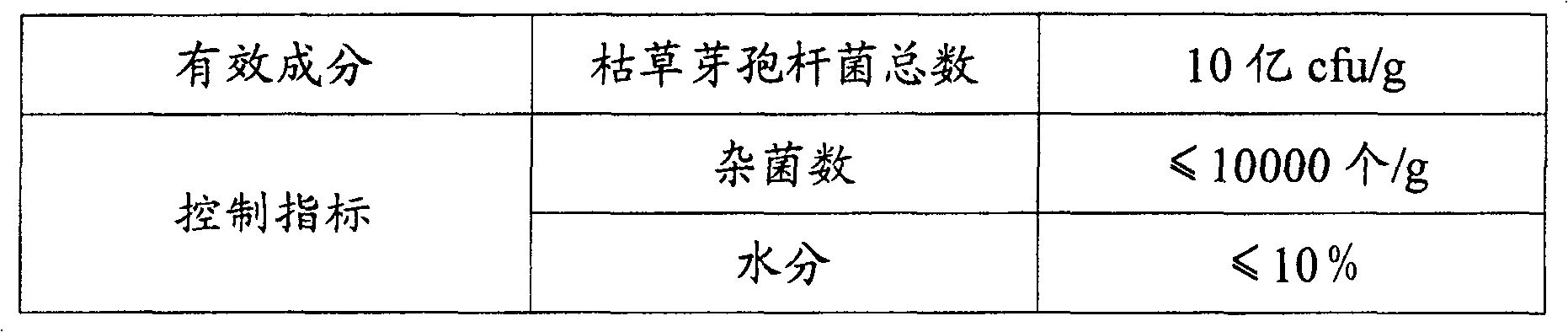

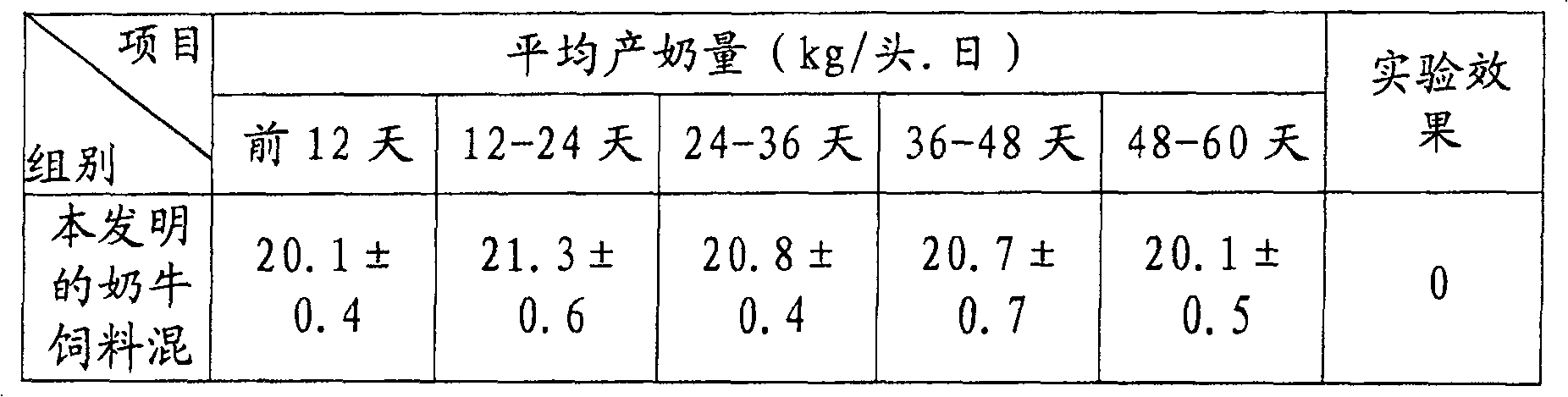

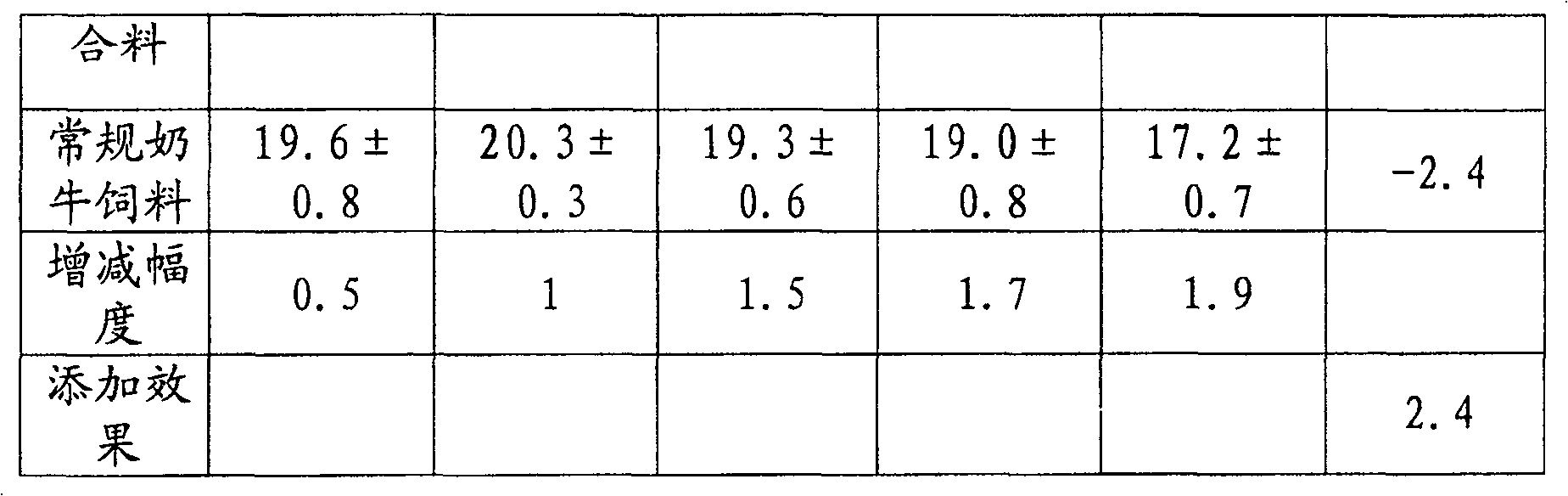

[0023] The raw materials of cow feed mixture are mixed according to the following ratio: soybean meal 4.0%, dephenolized cotton protein 5.0%, cotton meal 13.3%, sunflower meal 6.0%, rapeseed meal 6.0%, alcohol meal 9%, corn gluten meal 7.0%, alfalfa 4%, corn germ meal 12%, vermicelli bran 6.4%, compound protein 8.5%, castor meal 5.09%, calcium carbonate 5.1%, calcium hydrogen phosphate 4.8%, salt 4.0%, yeast 4.0%, soda 1.2%, diacetic acid Sodium 0.1%, Bacillus subtilis preparation 0.05%, Wanda enzyme 0.06%, additive 2%, and magnesium oxide 0.4%.

[0024] Among them, the raw materials that do not need to be crushed, such as salt, yeast, sodium diacetate, additives, Bacillus subtilis preparations, Wanda enzyme, magnesium oxide, etc., are weighed in proportion, and mixed with the mixer of the premixing unit for 3-6 minutes; Then weigh the mixed premix according to the ratio specified in the formula for each ton of finished product, and wait for feeding at the small material feedi...

Embodiment 2

[0026] The raw materials of cow feed mixture are mixed according to the following ratio: soybean meal 2.5%, dephenolized cotton protein 3.5%, cotton meal 16.3%, sunflower meal 4.5%, rapeseed meal 4.5%, alcohol meal 13.5%, corn gluten meal 5.5%, alfalfa 2.5%, corn germ meal 10.5%, vermicelli bran 8.9%, complex protein 9.0%, castor meal 3.59%, calcium carbonate 3.6%, calcium hydrogen phosphate 3.3%, salt 2.5%, yeast 2.5%, soda 1.7%, diacetic acid Sodium 0.1%, Bacillus subtilis preparation 0.05%, Wanda enzyme 0.06%, additive 2.5%, and magnesium oxide 0.4%.

[0027] Among them, the raw materials that do not need to be crushed, such as salt, yeast, sodium diacetate, additives, Bacillus subtilis preparations, Wanda enzyme, magnesium oxide, etc., are weighed in proportion, and mixed with the mixer of the premixing unit for 3-6 minutes; Then weigh the mixed premix according to the ratio specified in the formula for each ton of finished product, and wait for feeding at the small materi...

Embodiment 3

[0029] The raw materials of cow feed mixture are mixed according to the following ratio: soybean meal 2.0%, dephenolized cotton protein 3.0%, cotton meal 21.3%, sunflower meal 4.0%, rapeseed meal 4.0%, alcohol meal 13%, corn gluten meal 5.0%, alfalfa 2%, corn germ meal 10%, vermicelli bran 8.4%, complex protein 10.5%, castor meal 3.09%, calcium carbonate 3.1%, calcium hydrogen phosphate 2.8%, salt 2.0%, yeast 2.0%, soda 1.2%, diacetic acid Sodium 0.1%, Bacillus subtilis preparation 0.05%, Wanda enzyme 0.06%, additive 2%, and magnesium oxide 0.4%.

[0030] Among them, the raw materials that do not need to be crushed, such as salt, yeast, sodium diacetate, additives, Bacillus subtilis preparations, Wanda enzyme, magnesium oxide, etc., are weighed in proportion, and mixed with the mixer of the premixing unit for 3-6 minutes; Then weigh the mixed premix according to the ratio specified in the formula for each ton of finished product, and wait for feeding at the small material feed...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com