Metal heald frame and heald shaft for a loom

A technology of healds and heald frames, which is applied in the field of heald frames and heald shafts for looms, and can solve the problems of complex and expensive embodiments

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

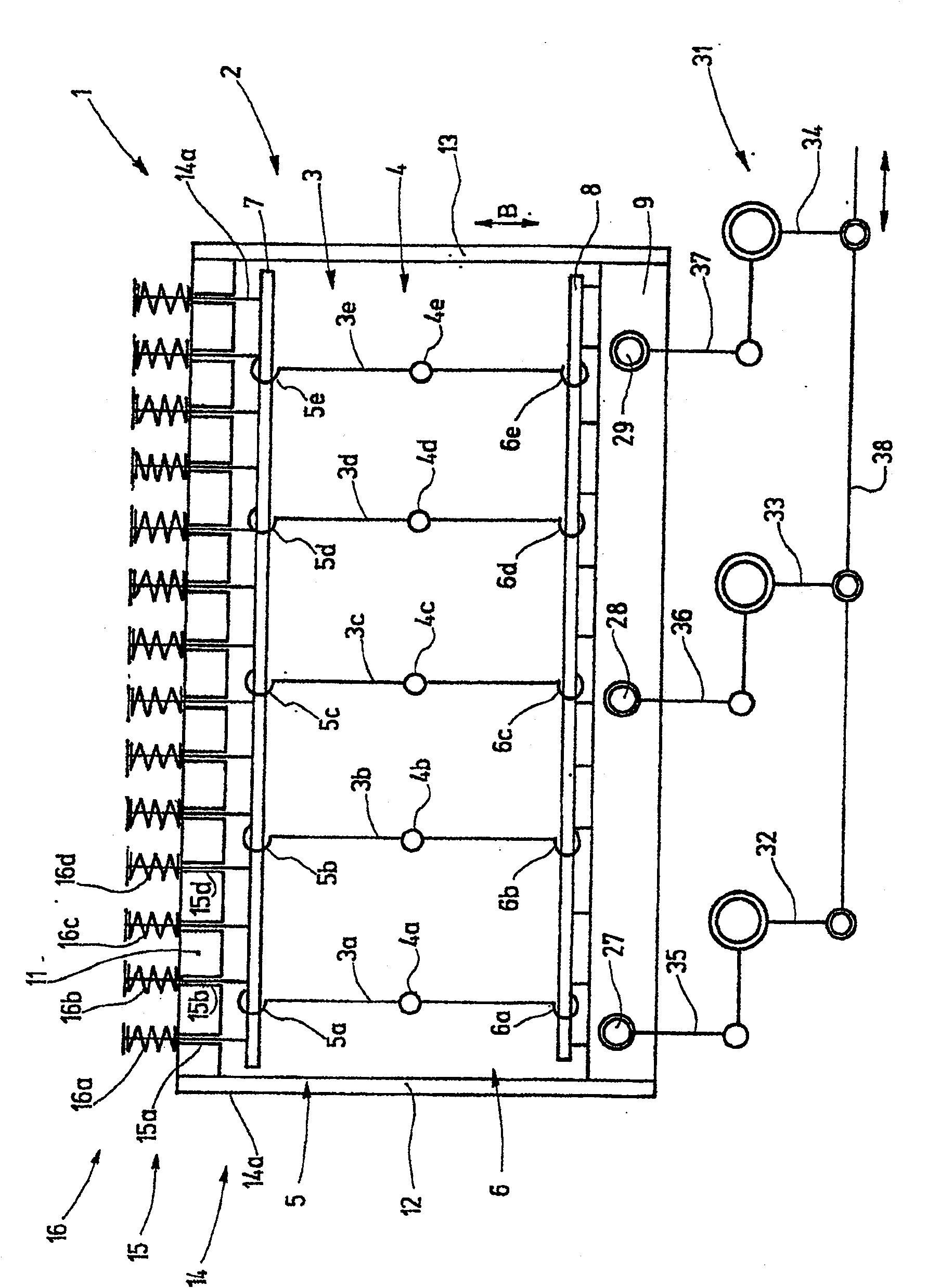

[0026] figure 1 The heald shaft 1 of the weaving machine, which is not shown further, is shown. The heald shaft 1 comprises a heald frame 2 carrying a plurality of healds 3 arranged parallel to one another. For display purposes, figure 1 Only five individual healds 3a, 3b, 3c, 3d, 3e are shown. In fact, more healds are spaced closer together. Each heald 3 has approximately in its center an eyelet 4 (4a, 4b, 4c, 4d, 4e) through which each warp thread passes through a corresponding heald eye. Each heald 3 is provided with a heald head 5, 6 (5a, 5b, 5c, 5d, 5e, 6a, 6b, 6c, 6d, 6e) on each end, by which the heddle 3 is held in the On the heald support rail 7,8. The heald support rails 7 , 8 are supported by the heald frame 2 and extend at a distance from one another and parallel to the direction of movement B of the heald frame 2 , which corresponds to the longitudinal direction of the heald 3 . The heald support rail 8 is held rigidly on the heald frame 2 , which comprises ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com