Axial interval regulator for warping machine lead screw

A technology of a gap adjustment device and a screw shaft, which is used in warping machines, other manufacturing equipment/tools, textiles and papermaking, etc., can solve the problems of reducing the performance and life of the screw, inconvenient measurement and assembly, and troublesome processing. , to achieve the effect of improving manufacturability, strong axial load bearing capacity and prolonging service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

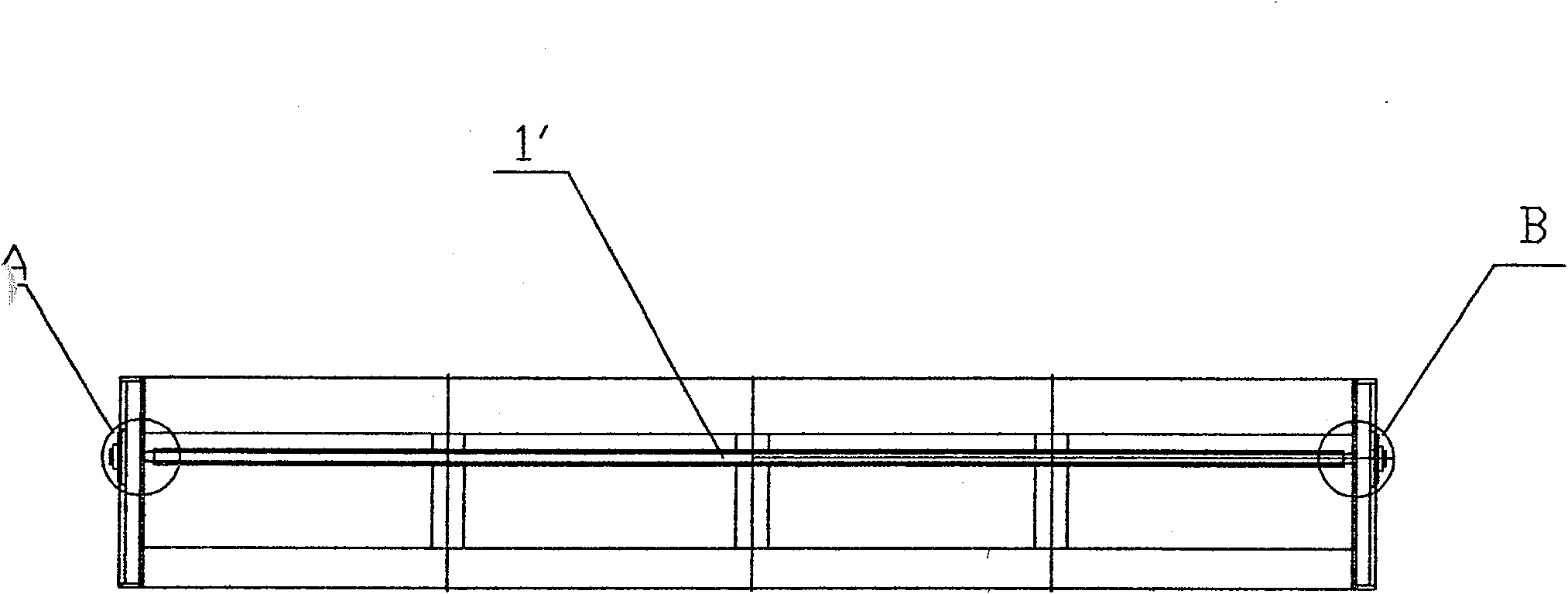

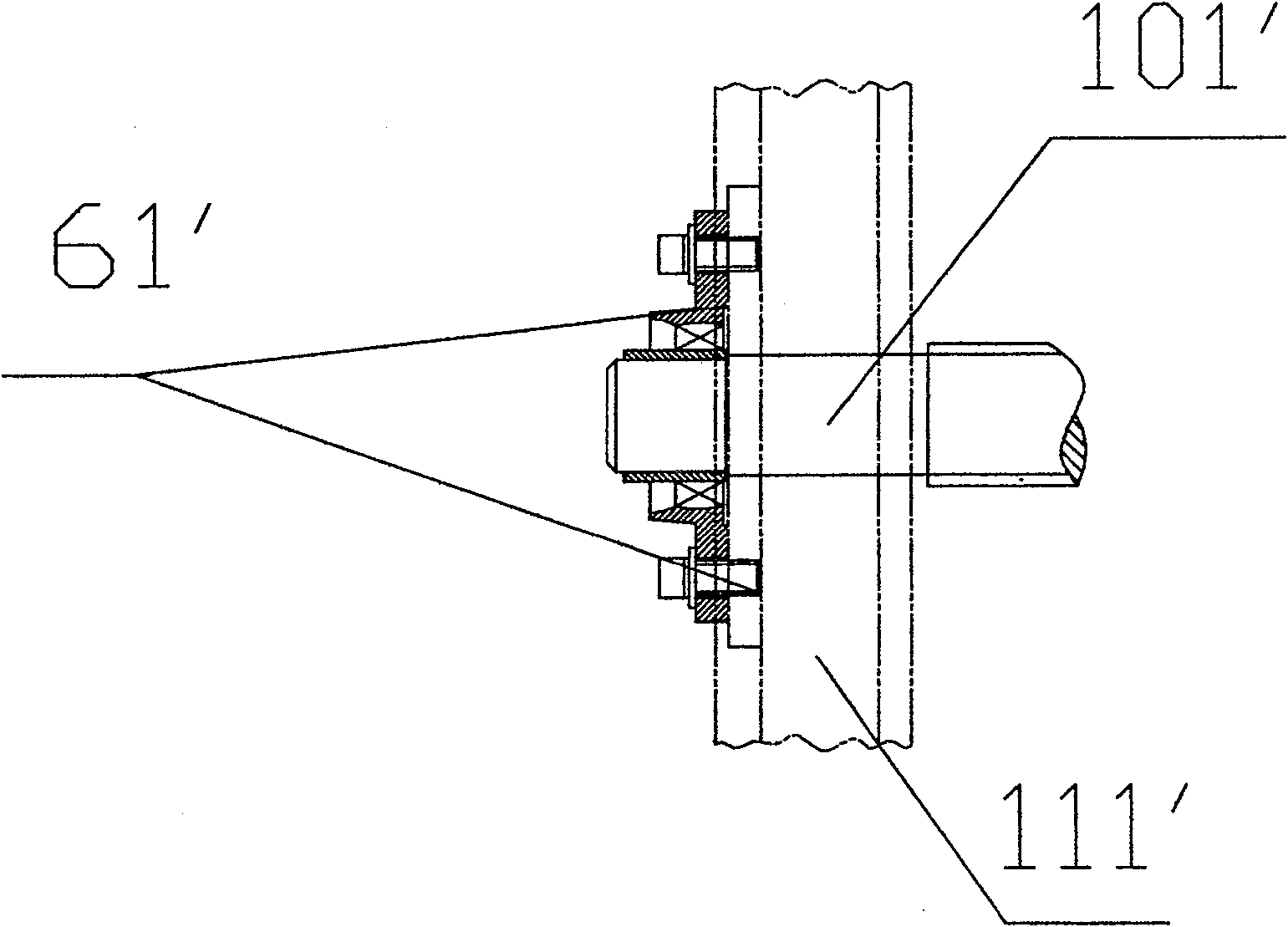

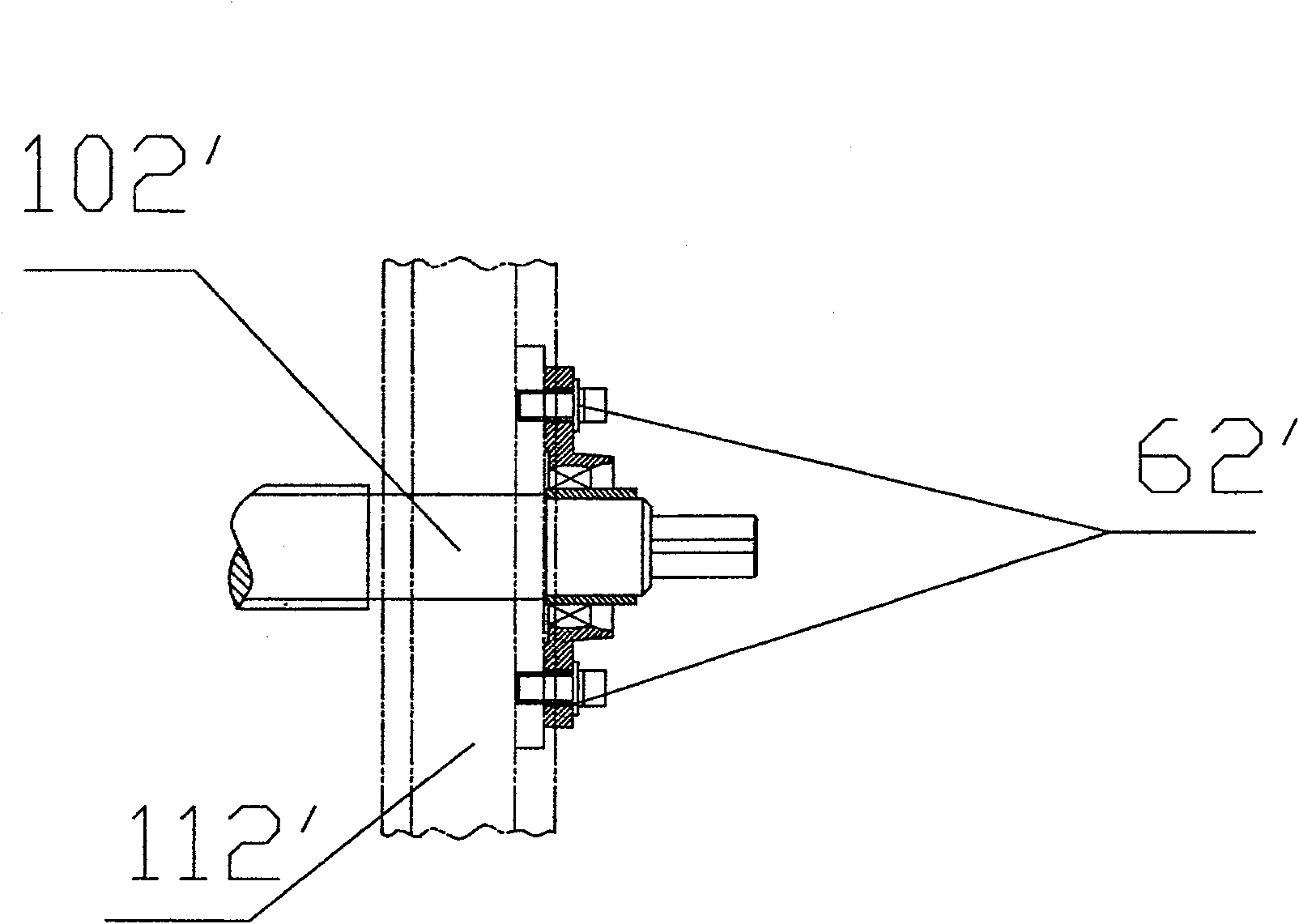

[0016] Such as Figure 4 to Figure 6 As shown, the present invention includes a lead screw 1, the two ends of which are respectively connected with a shaft 101 and a shaft 102, and the shaft 101 and the shaft 102 respectively pass through the bearing seat plate 111 and the bearing seat seat plate 112 at both ends, and the bearing seat 61 and the bearing The seat 62 is fixed on the bearing seat plate 111 and the bearing seat plate 112, and a deep groove ball bearing 7 is also arranged between the shaft 102 at one end and the bearing seat 62, and the deep groove ball bearings 7 are symmetrically arranged on the upper and lower sides of the shaft 102 respectively. 2, separated and fixed by a spacer ring 8 between them, two thrust ball bearings 5 are arranged symmetrically up and down on the shaft 102 in front of the bearing seat 62, and an adjusting nut 4 is fixed in front of the thrust ball bearing 5, and the shaft 102 and the adjustment Adjusting screw rods 2 are movably conn...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com