Corn snapping bar provided with surface having bionic giometric structure

A technology of geometric structure and ear picking roller, which is applied in agricultural machinery and implements, harvesters, agriculture, etc., can solve the problems of lack of application value, increase of ear gnawing rate and ear gnawing degree, etc., so as to increase the grabbing ability and reduce the grabbing capacity, the effect of increasing the coefficient of friction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

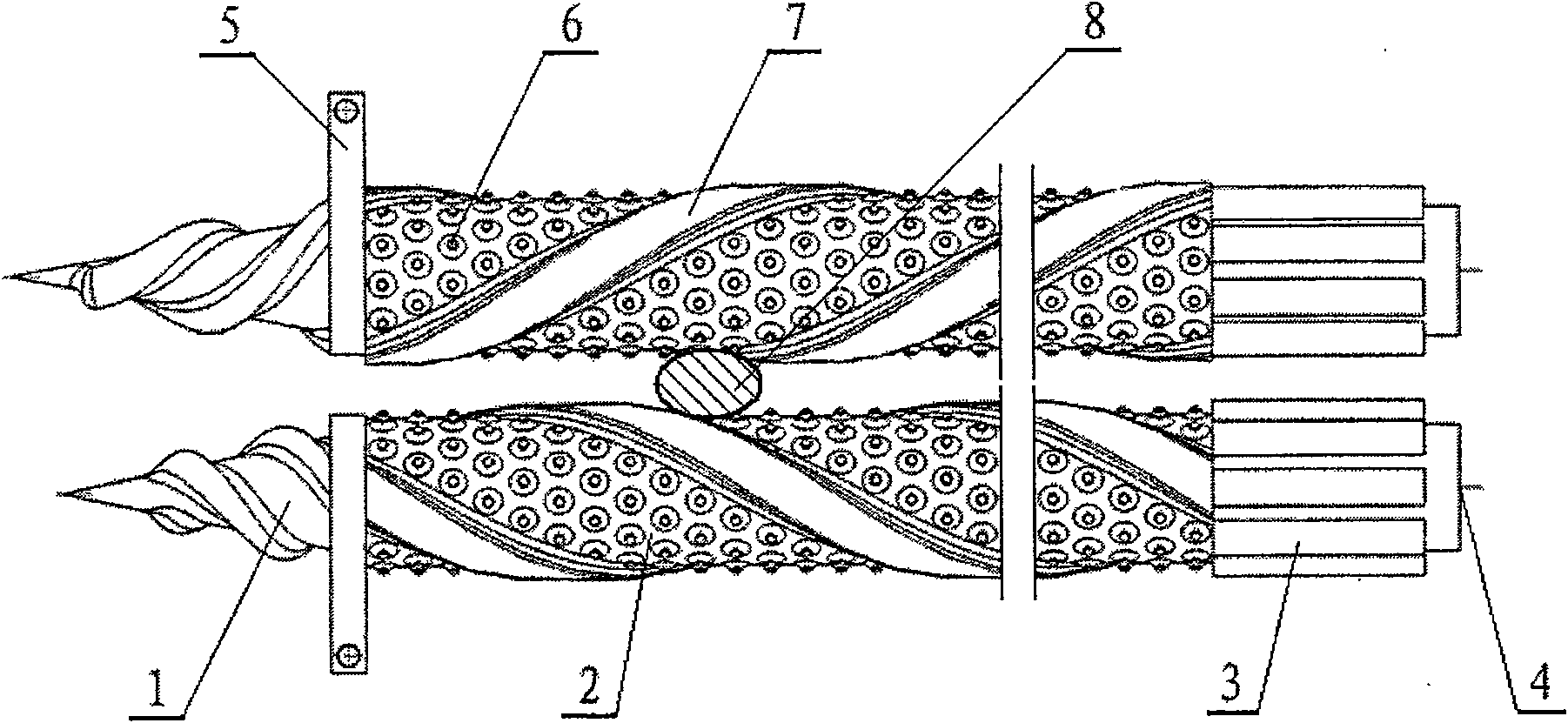

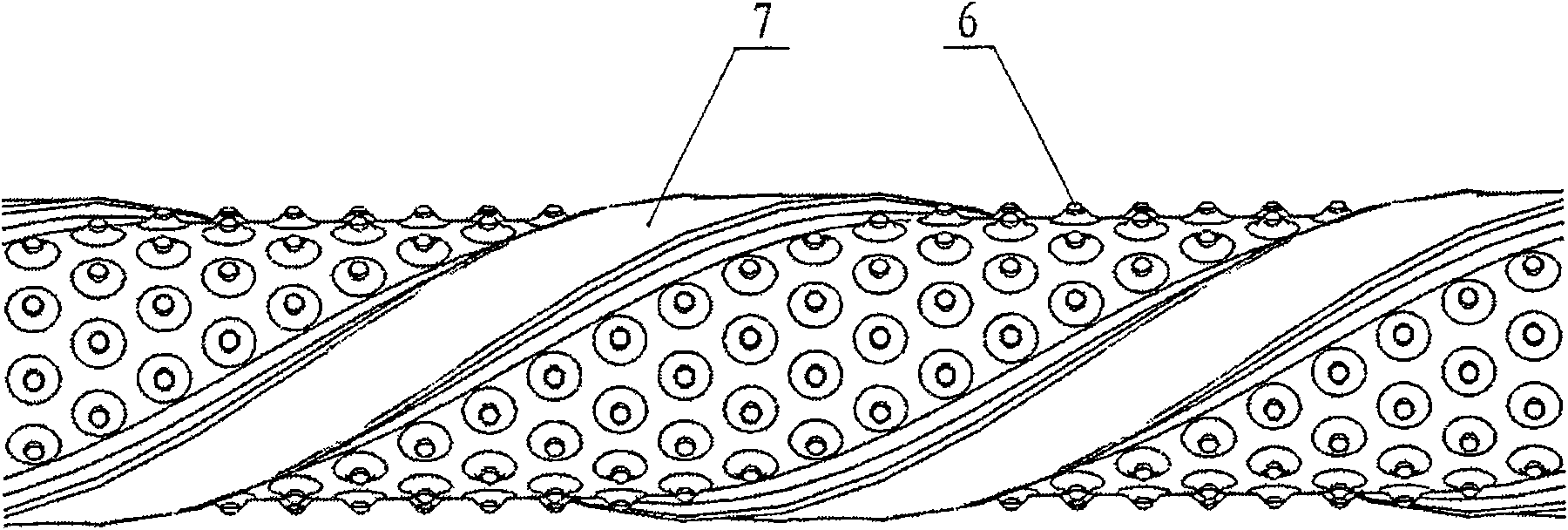

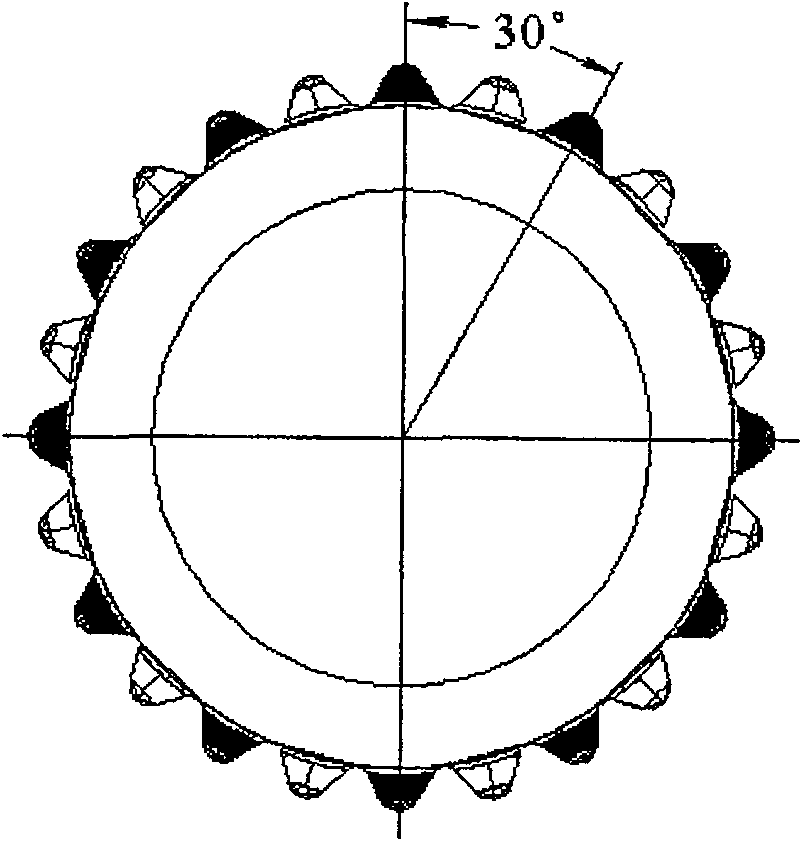

[0032] The specific structure of the novel corn picking roller with bionic geometric structure surface structure of this example is given by figure 1 , figure 2 is shown with Figure 3. The new type of corn picking roller in this example has the following structural features: the small-diameter roller surface of the picking roller is distributed with a bionic geometric structure surface structure 6 arranged in a spiral along the axis of the roller shaft and two guiding helical wide ribs 7. The surface structure 6 of the bionic geometric structure in this example adopts a convex hull structure, and the guiding spiral wide rib 7 adopts a spiral wide rib (the width of the rib is 15-20mm). The specific structure is: the convex hull structure distributed on the cylindrical surface of the small-diameter roller of a single ear picking roller is approximately equilateral triangle distribution on the unfolded surface of the cylindrical surface, the convex hull spacing is 12-15mm, and ...

Embodiment 2

[0034] The specific structure of the novel corn picking roller with bionic geometric structure surface structure of this example is given by figure 1 , figure 2 is shown with Figure 3. The novel corn ear picking roller with the bionic geometric structure surface structure described in this example is different from Example 1 in that the bionic geometric structure surface structure 6 of this example is a pit-shaped structure arranged in a spiral along the axis of the roller shaft. The rest are the same as described in Example 1.

Embodiment 3

[0036] The specific structure of the novel corn picking roller with bionic geometric structure surface structure of this example is given by figure 1 , figure 2 is shown with Figure 3. The novel corn picking roller with the bionic geometric structure surface structure described in this example is different from Example 1 and Example 2 in that: the bionic geometric structure surface structure 6 of this example is a convex hull / concave arranged in a spiral shape along the axis of the roller shaft. Pit-type structure, that is, the surface of the ear-picking rollers installed on the higher side is arranged in a spiral shape along the axis of the roller shaft, and the surface of the ear-picking rollers installed on the lower side is arranged in a spiral shape along the axis of the roller shaft. The pit-type structure of the cloth. The rest are the same as described in Example 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com