Quantitative filling valve containing pulp type beverage

A technology for filling valves and beverages. It is applied in the cocks including cutting devices, valve operation/release devices, packaging, etc. It can solve the problems of inaccuracy, large filling volume errors, and no quantitative filling. The machine structure is simple, the bottle mouth is guaranteed to be clean, and the filling precision is high.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

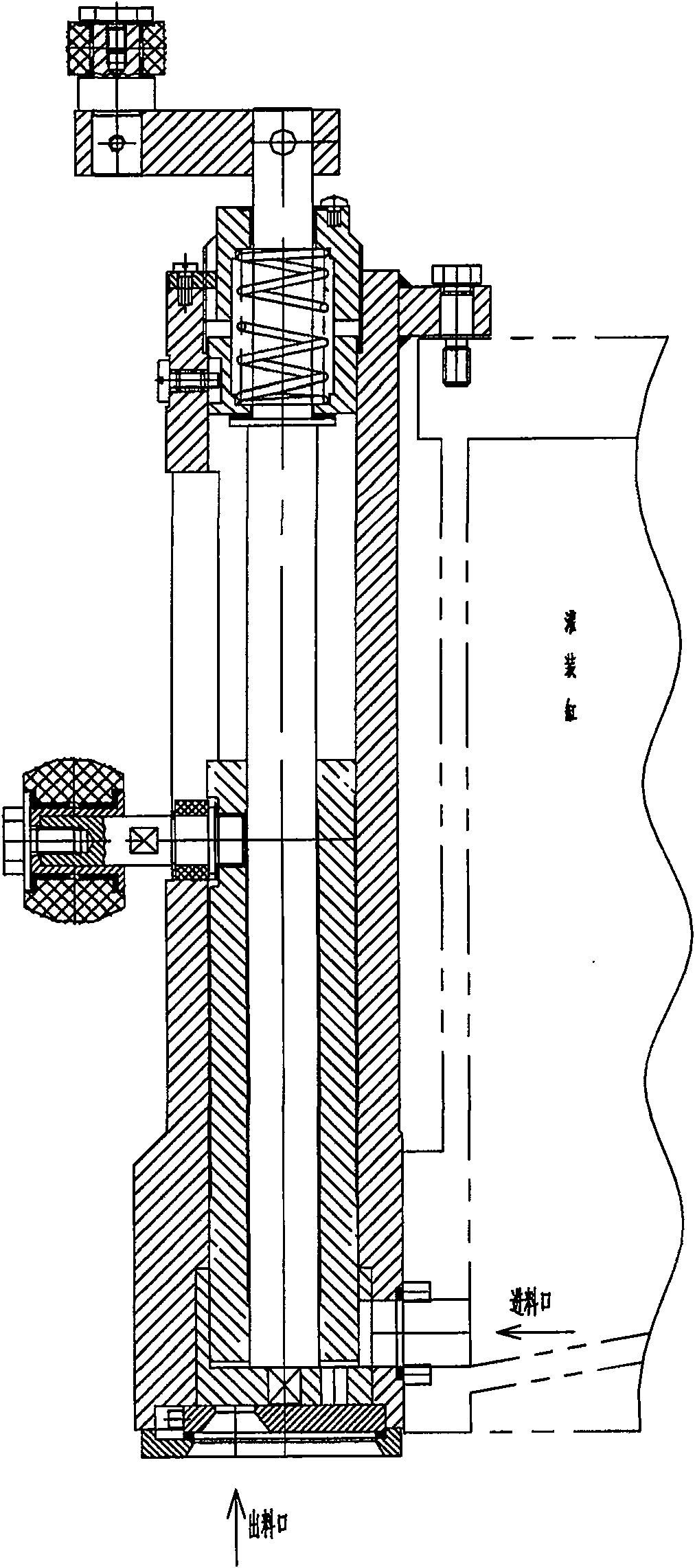

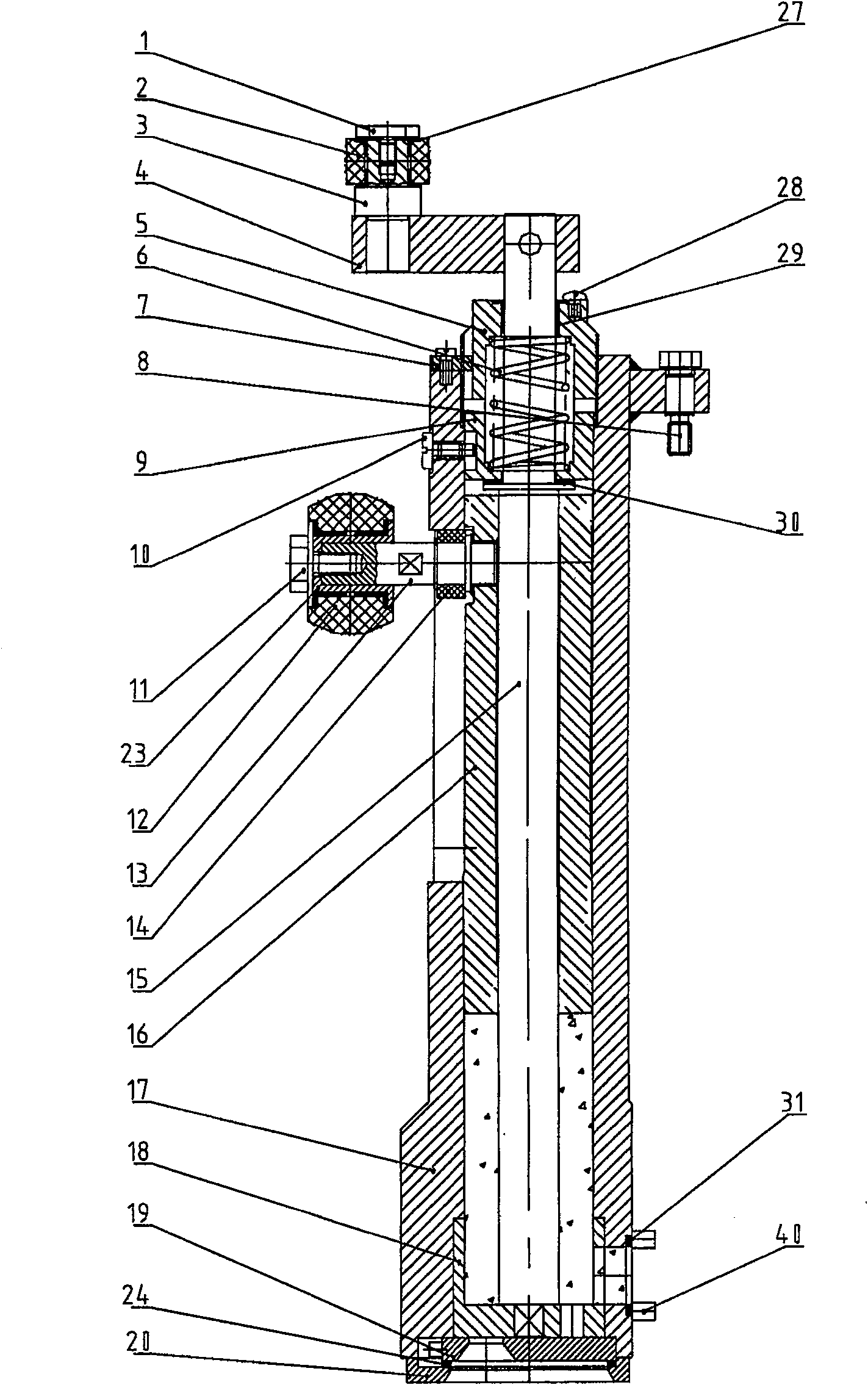

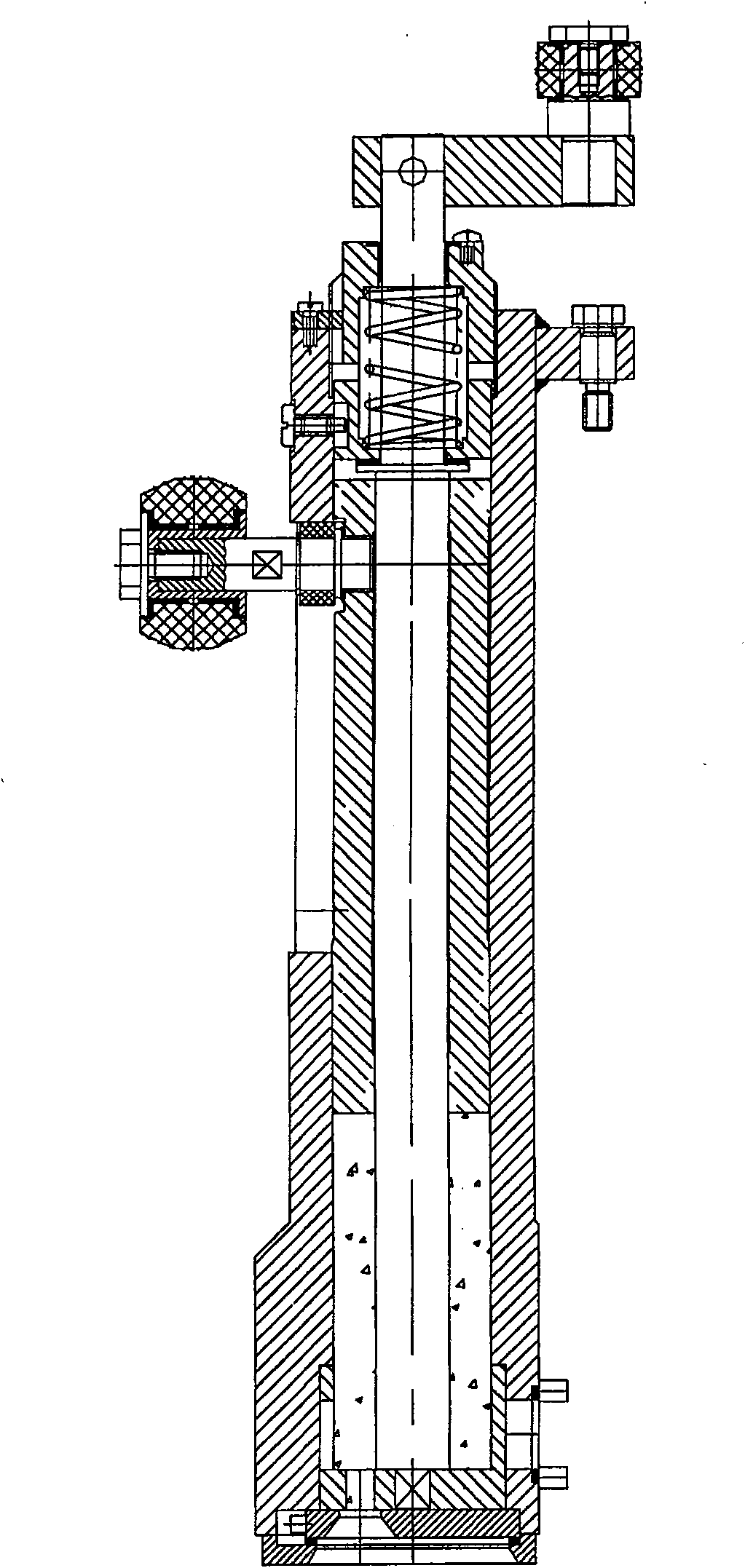

[0051] The quantitative filling valve of pulp-containing beverage according to the present invention is mainly composed of plunger 16, valve seat 17, control ring 18 and control shaft 14, among which plunger 16, valve seat 17, control ring 18, Manipulation shaft 15 parts such as figure 2 , 4 As shown, the plunger 16 extends into the cavity of the valve seat 17 from top to bottom; a waist-shaped groove is opened on one side of the valve seat 17, and the small shaft 13 is horizontally connected to the plunger 16 through a gasket 25 and extends from the waist-shaped groove. Out, the guide roller 14 is installed on the small shaft 13 through the retaining ring 33 and rolls in the waist-shaped groove of the valve seat 17, the sleeve 23 is installed on the extension end of the small shaft 13 through the screw 11, and the lifting roller 12 is installed on the sleeve through the bearing 34. 23, the lifting roller 12 is controlled by an external cam.

[0052] Such as figure 2 , 4...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com