Food chiller with optimized air flow

A refrigerator, air flow technology, applied in food preservation, machines using electrical/magnetic effects, preservation of fruits/vegetables by freezing/refrigeration, etc., can solve problems such as reduced efficiency, heat loss, pressure drop, etc., to achieve optimal cooling Effects of air flow, optimized heat transfer efficiency, low manufacturing cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

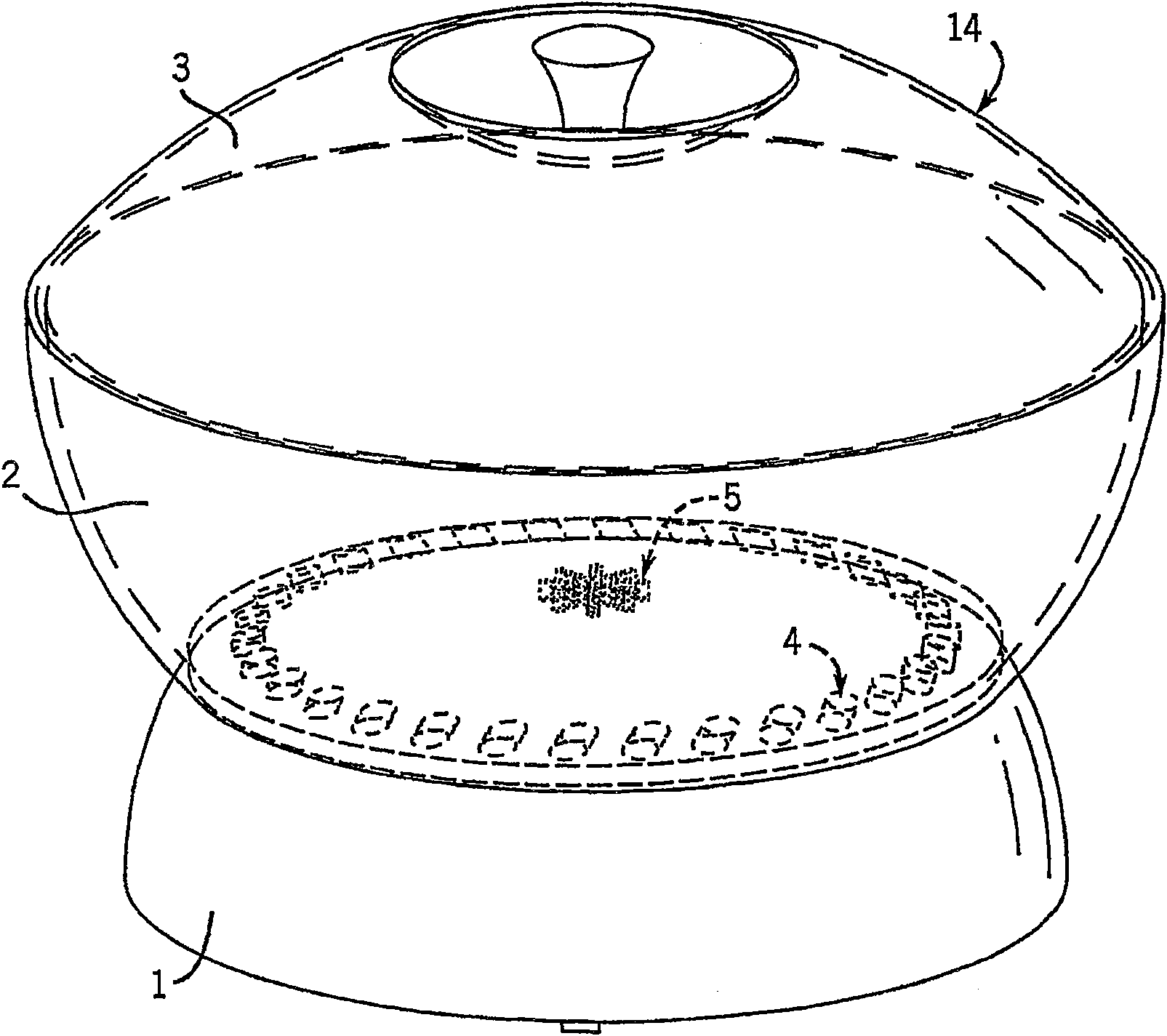

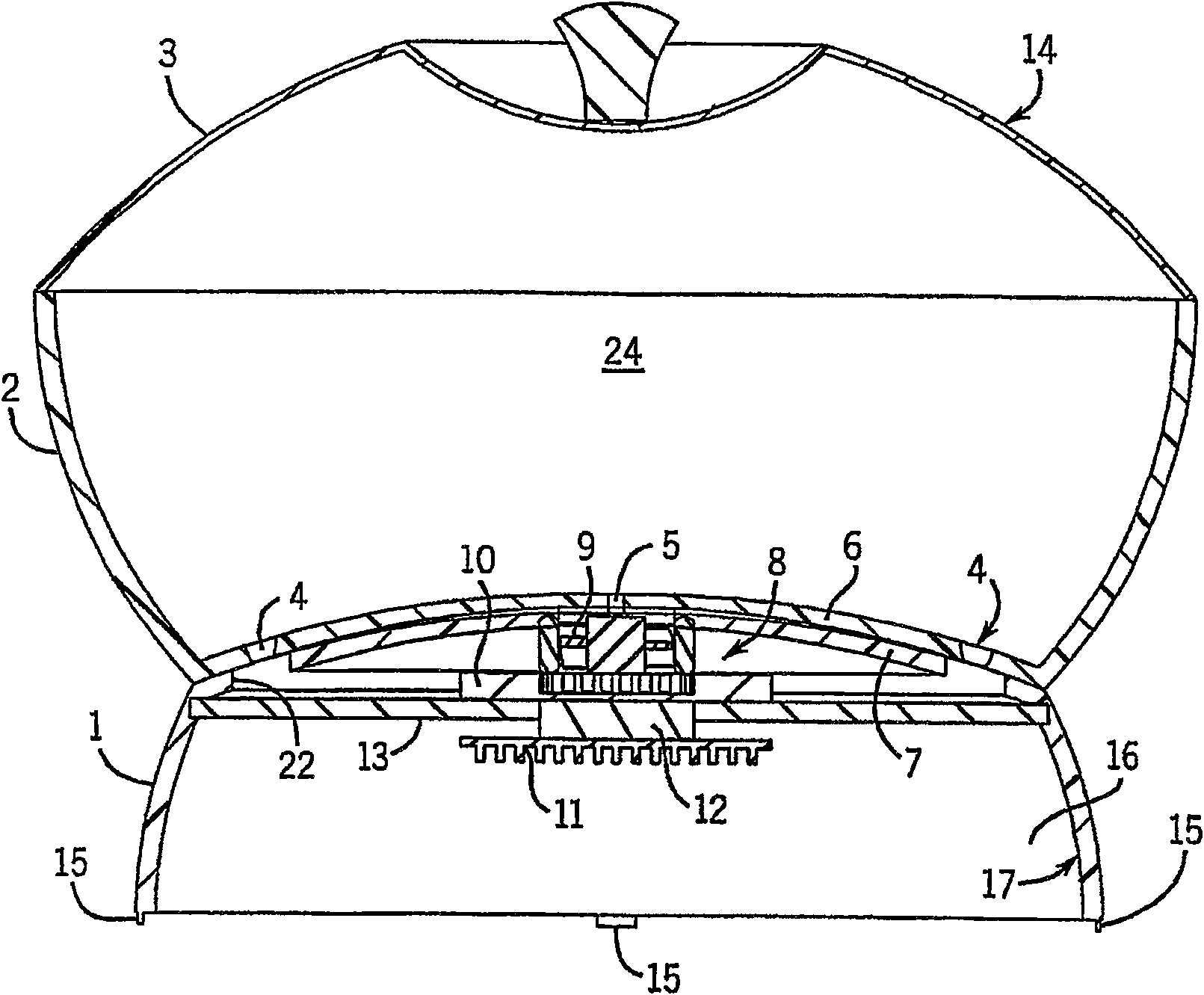

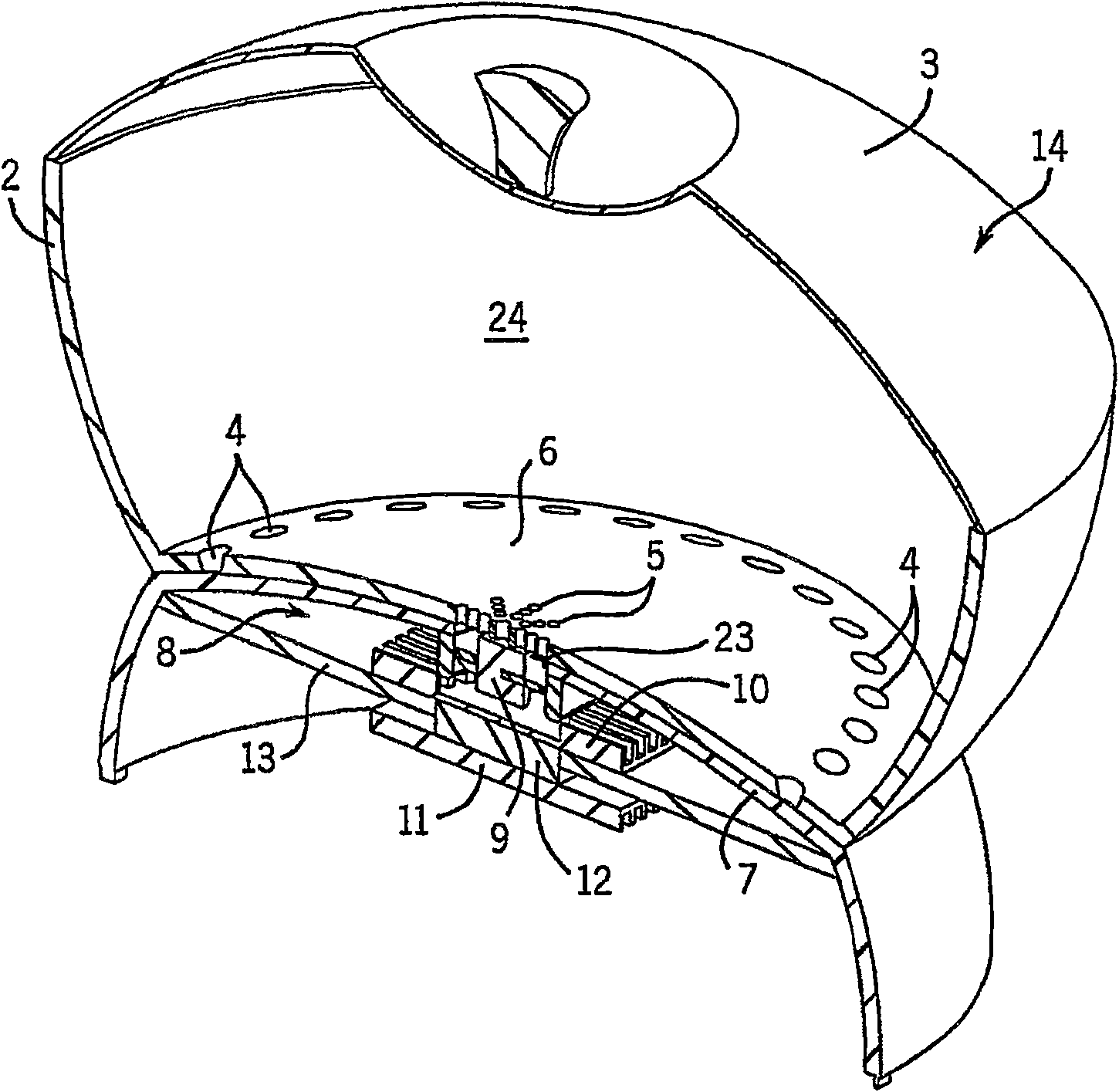

[0033] figure 1A fruit cooler 14 of one embodiment of the present invention is shown. The fruit refrigerator comprises a support base 1 for supporting the refrigerator on a horizontal plane. Within this base there is space for the various components of the cooling system, which will be described in detail here. The removable container 2 is placed on the base 1 . The removable cover 3 provides access to the food to be preserved. The interior of the container 2 is provided with inlet openings 4 for distributing cooling air into the container. The centrally located outlet opening 5 provides a return channel for the air. Once flowing through the opening 5 , the air will be cooled again and exit through the opening 4 . Although this is the preferred embodiment, it is also possible to reverse the gas flow so that opening 5 is used as an inlet opening and opening 4 is used as an outlet opening. The base 1, the container 2 and the removable lid 3 may all be made of injection mol...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com