Cross head large diesel oil engine

A crosshead, diesel engine technology, applied in the direction of crossheads, mechanical equipment, engine components, etc., can solve the problems of large stress, complexity, deformation of bearing pads, etc. of the bearing seat, and achieve the effect of easy absorption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

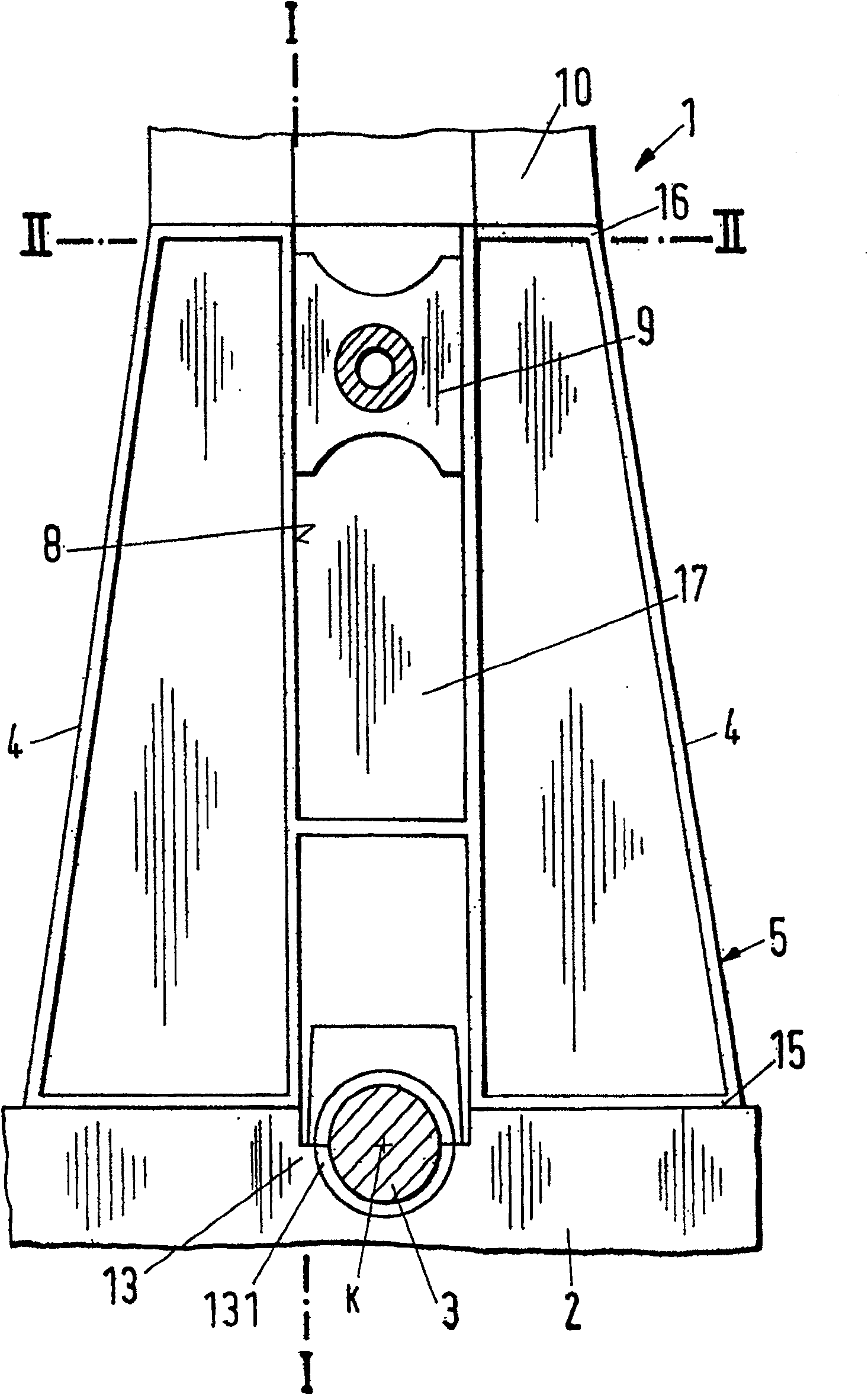

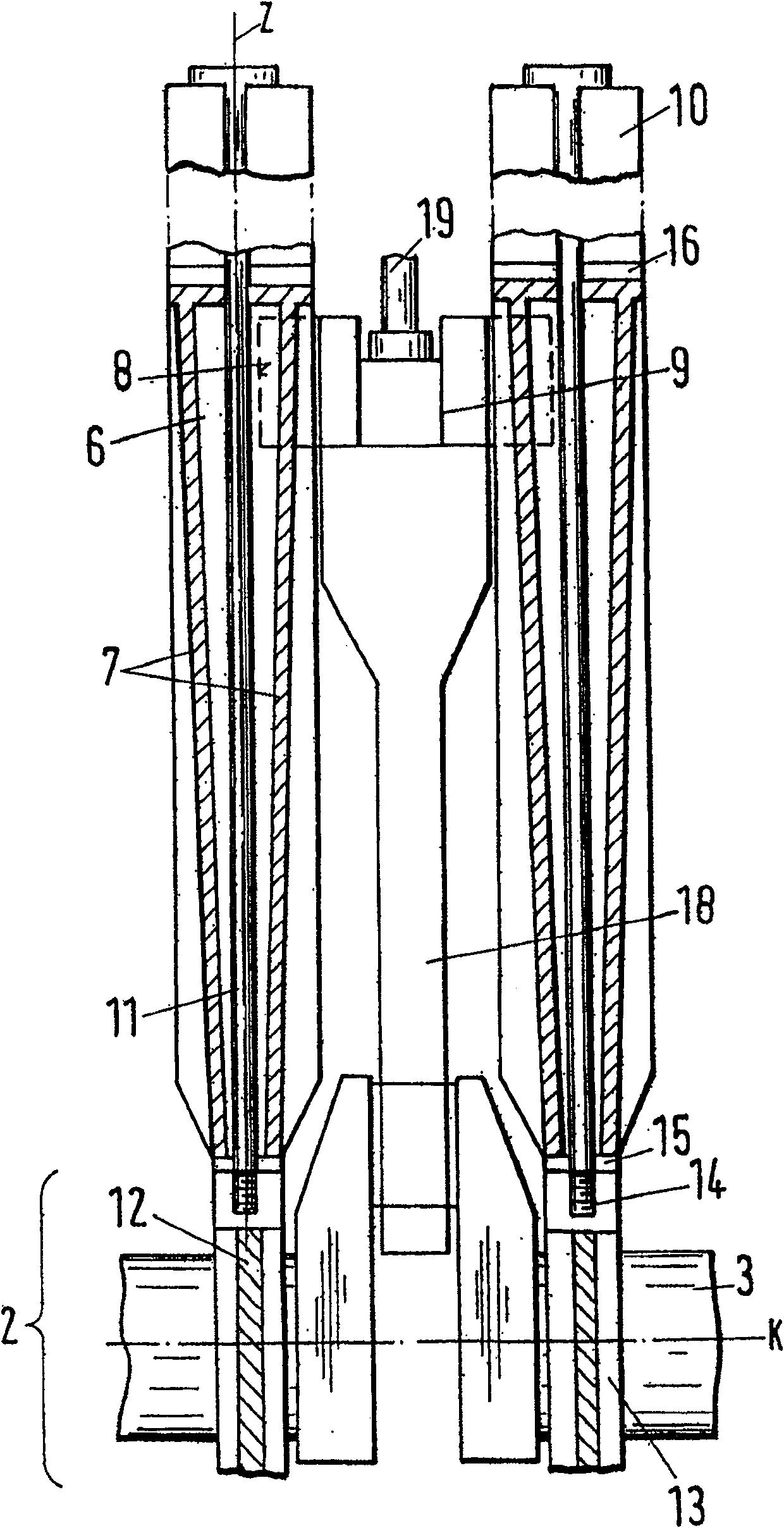

[0021] The crosshead large diesel engine according to the invention, designated hereinafter as a whole by the reference numeral 1, is designed in particular as a two-stroke large diesel engine 1 with longitudinal scavenging, which is widely used, for example, in ships.

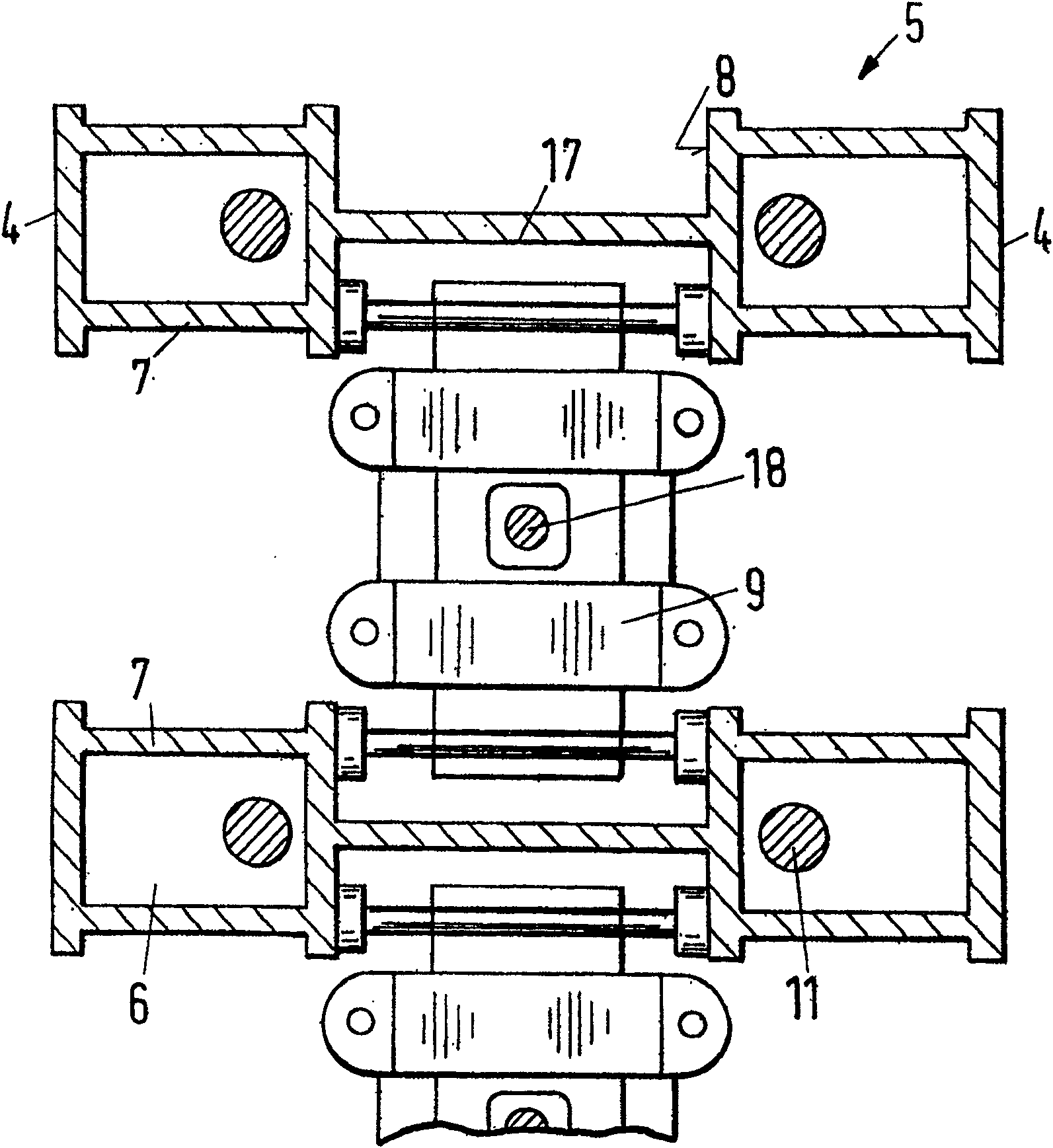

[0022] figure 1 A known form of a crosshead large diesel engine 1 is schematically shown in section, having a base plate 2 , a stator 5 and a cylinder part 10 . The cylinder section 10 is used in a known manner to receive cylinders, not shown. The stator 5, which has been formed, for example, by welding steel sheets together, has a sheet metal base plate 15 and two outer walls 4 and together with sliding surfaces 8 extending vertically according to the figures form two frames, which are conical in cross-section They are connected to each other by a common sheet metal top plate 16 . The two vertically extending opposite sliding surfaces 8 are supported by a central wall 17 arranged between the two conical fra...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com