Noise insulation block on upper part and internal side of A pole of car and uses thereof

A soundproof block and car technology, applied in the field of auto parts, can solve problems affecting the comfort of drivers and passengers

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

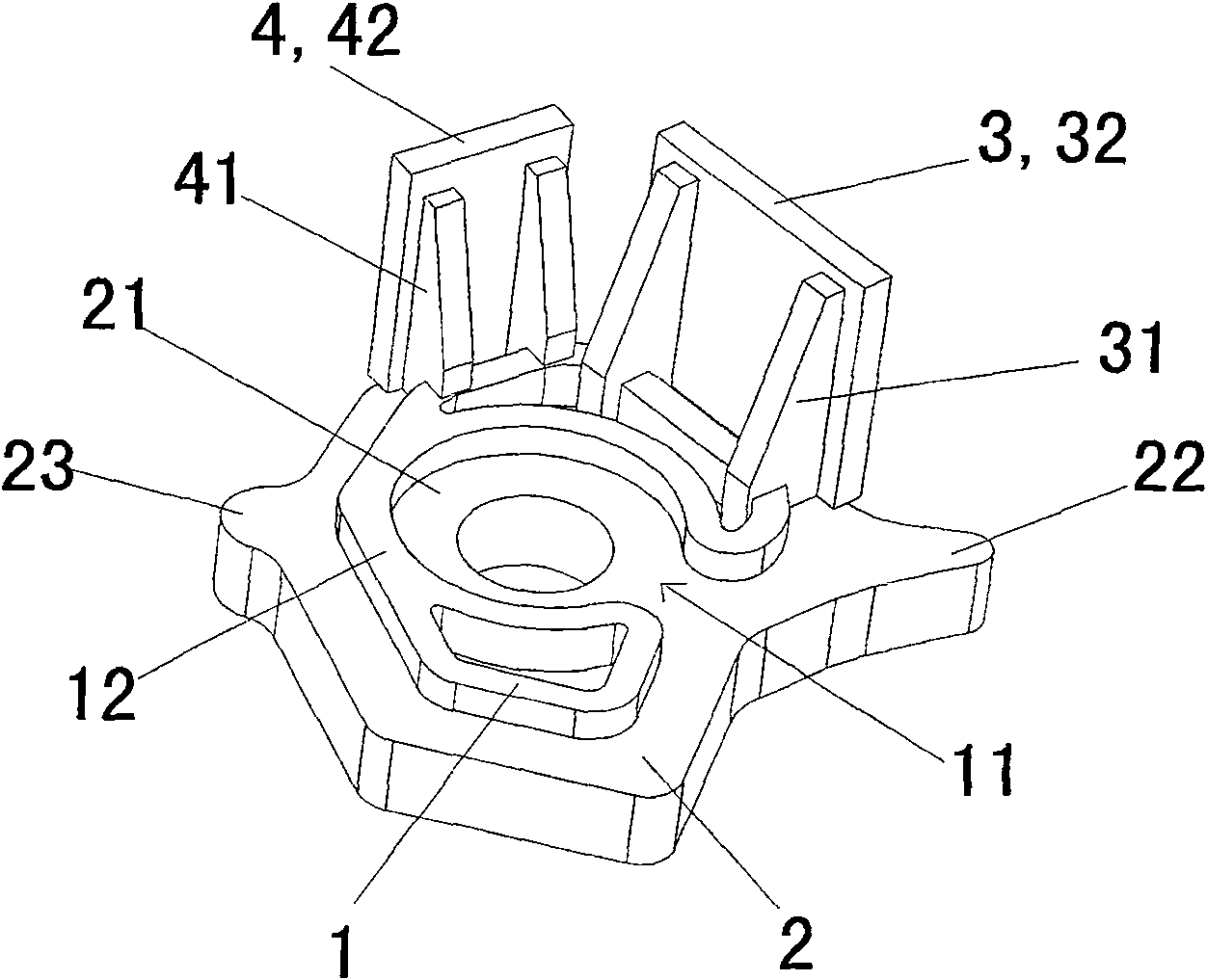

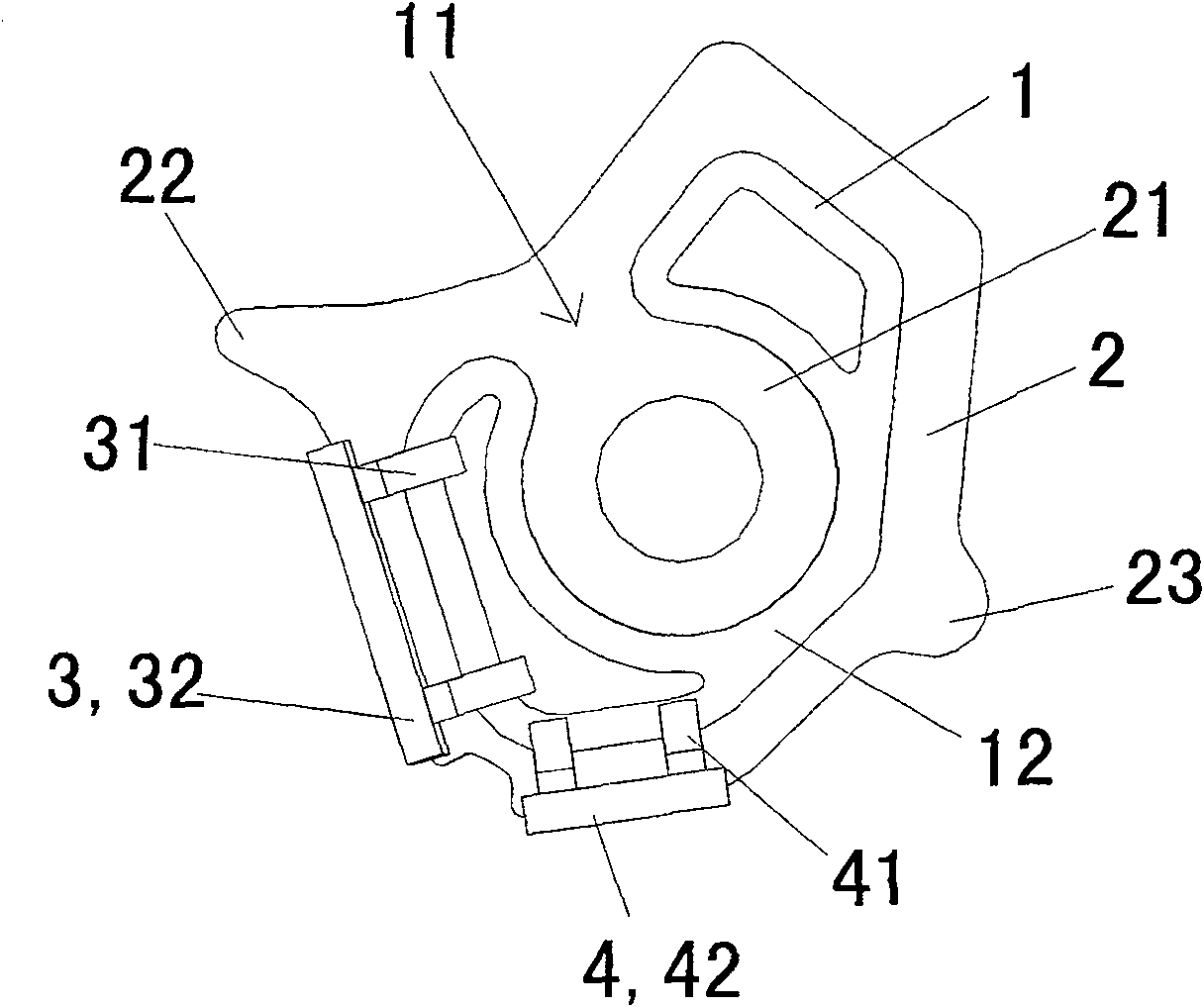

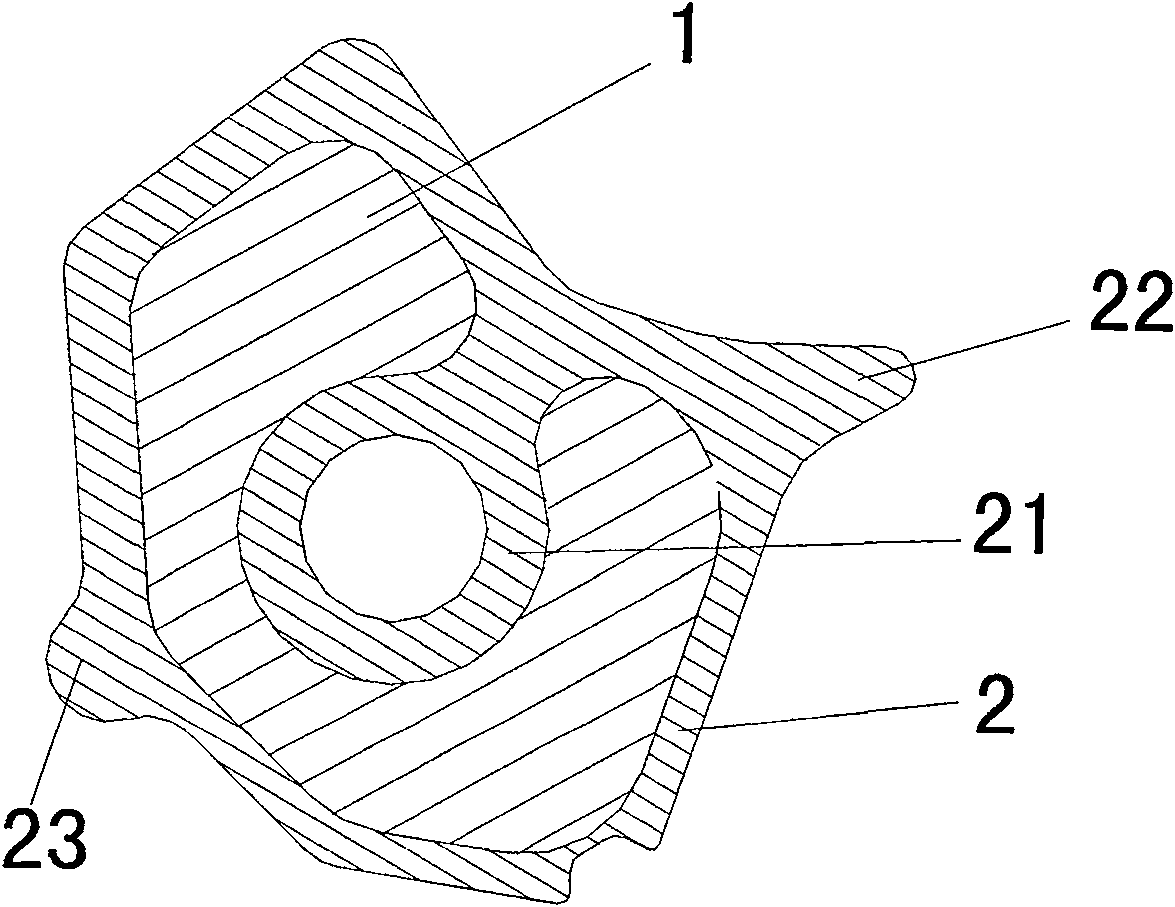

[0015] see figure 1 , with reference to figure 2 , image 3 , the upper inner side of the A-pillar of a car according to the present invention is used for presetting in the inner cavity of the upper inner side of the A-pillar of a car during the manufacturing process of the car body. The sound insulation block is in the shape of a polyhedron as a whole, and includes a skeleton 1 and a foam body 2 . The entire sound-insulating block has a plane shape similar to the section of the vehicle body cavity in the upper inner side of the A-pillar of the car, and leaves a gap with the periphery of the corresponding section for foaming and expansion of the foam body.

[0016] An opening 11 is provided on one side of the plate-shaped frame 1, a hole 12 is provided in the middle of the plate-shaped frame 1 and communicated with the above-mentioned opening, and a groove for embedding foam is provided on the periphery of the plate-shaped frame 1 , two adjacent sides of the plate frame 1 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com