Method for adjusting the angular travel of a wiper mechanism by modifying the length of a crank, and crank comprising a deformable section

A crank and wiper technology, which is applied in the field of changing the length of the crank to adjust the angular stroke of the wiper mechanism and a crank including a deformable segment, which can solve the problems of complexity, the exact position of the ball joint cannot be durable, and is not reliable enough

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

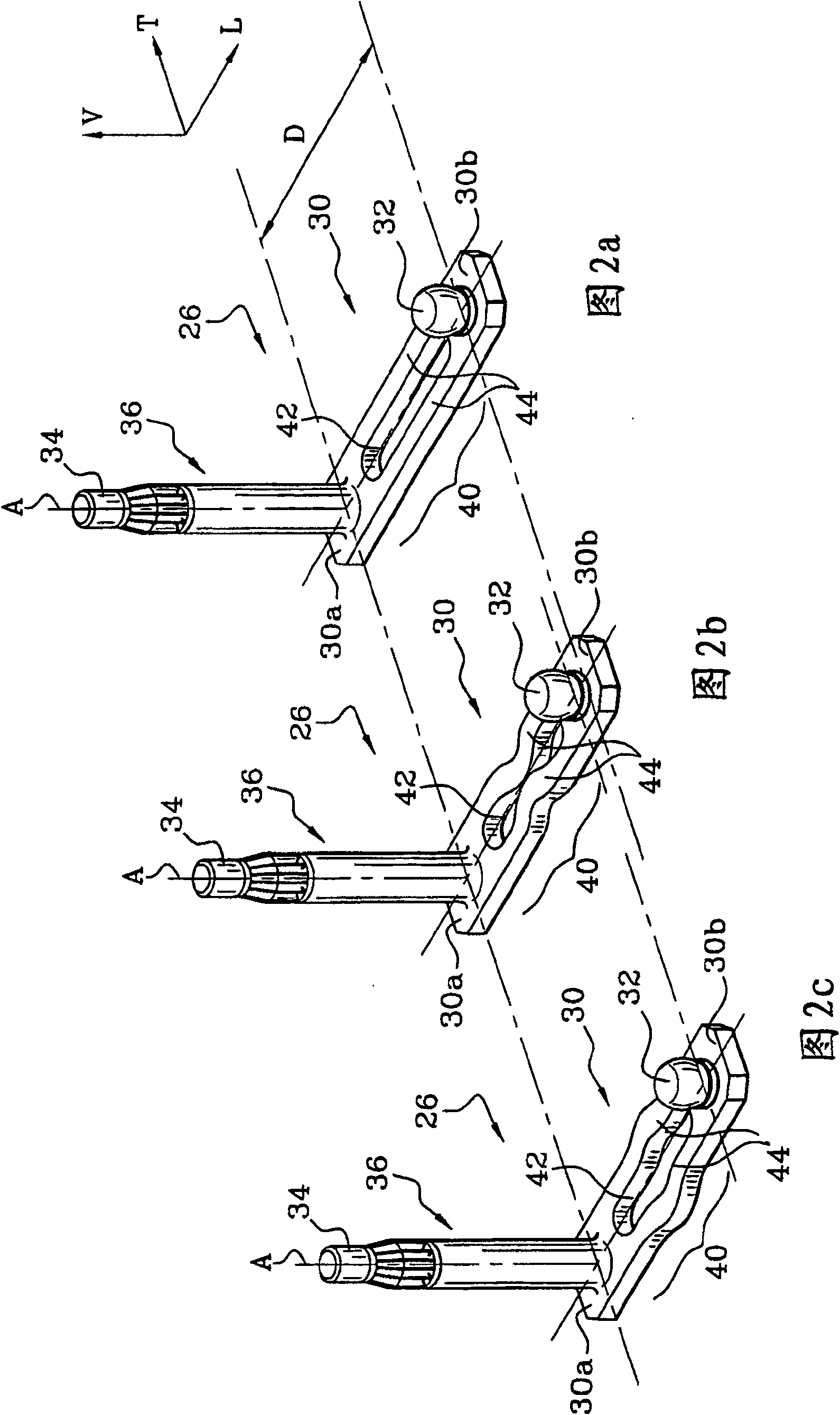

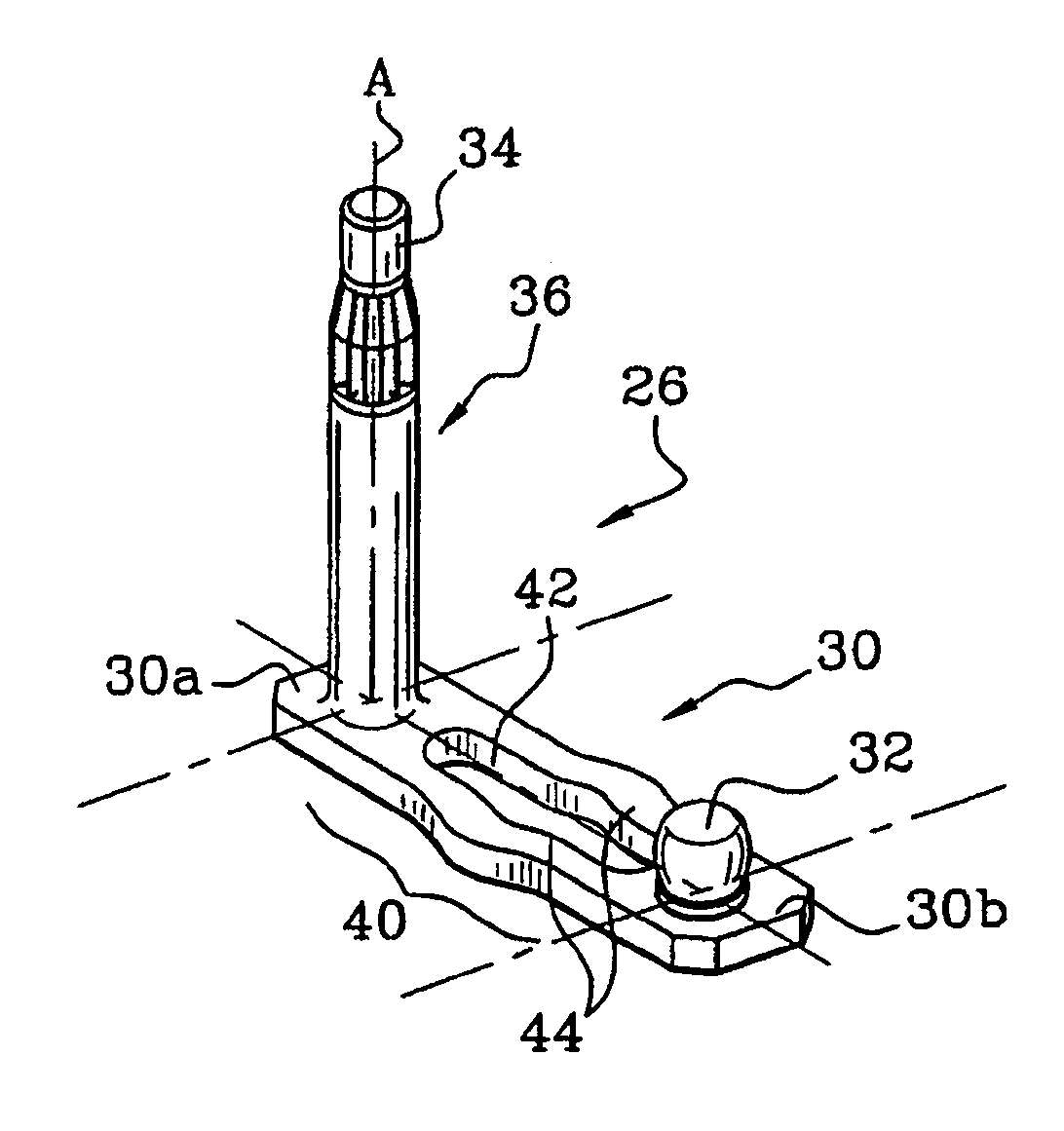

[0024] To describe the invention, in a non-limiting manner, as follows Figure 2a Marks V, L, and T shown in indicate vertical, longitudinal, and transverse directions.

[0025] In the following description, the same, similar and similar parts are denoted by the same numerals.

[0026] figure 1 A conventional wiper mechanism 20 for a windshield of a motor vehicle (not shown in the figure) is shown in FIG. The wiper brushes are movable in rotation about an approximately vertical axis A. The wiper mechanism 20 comprises a linkage system consisting of a transmission rod 24 and a crank 26 which connect the wiper brush 22 with a mechanical reduction gear 28 which ensures the drive of the wiper mechanism 20 .

[0027] Such as Figures 2a to 2c As shown, each crank 26 is known to have a generally flat body 30 extending longitudinally in a horizontal plane and having a first end 30 a hinged about the vertical axis of rotation of the associated wiper brush 22 .

[0028] The second...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com