Fuel-jetting system

A fuel injection system, fuel injection technology, applied in the direction of fuel injection device, fuel injection control, charging system, etc., can solve the problem that the fuel injection amount cannot be prevented from deviating from the target amount, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

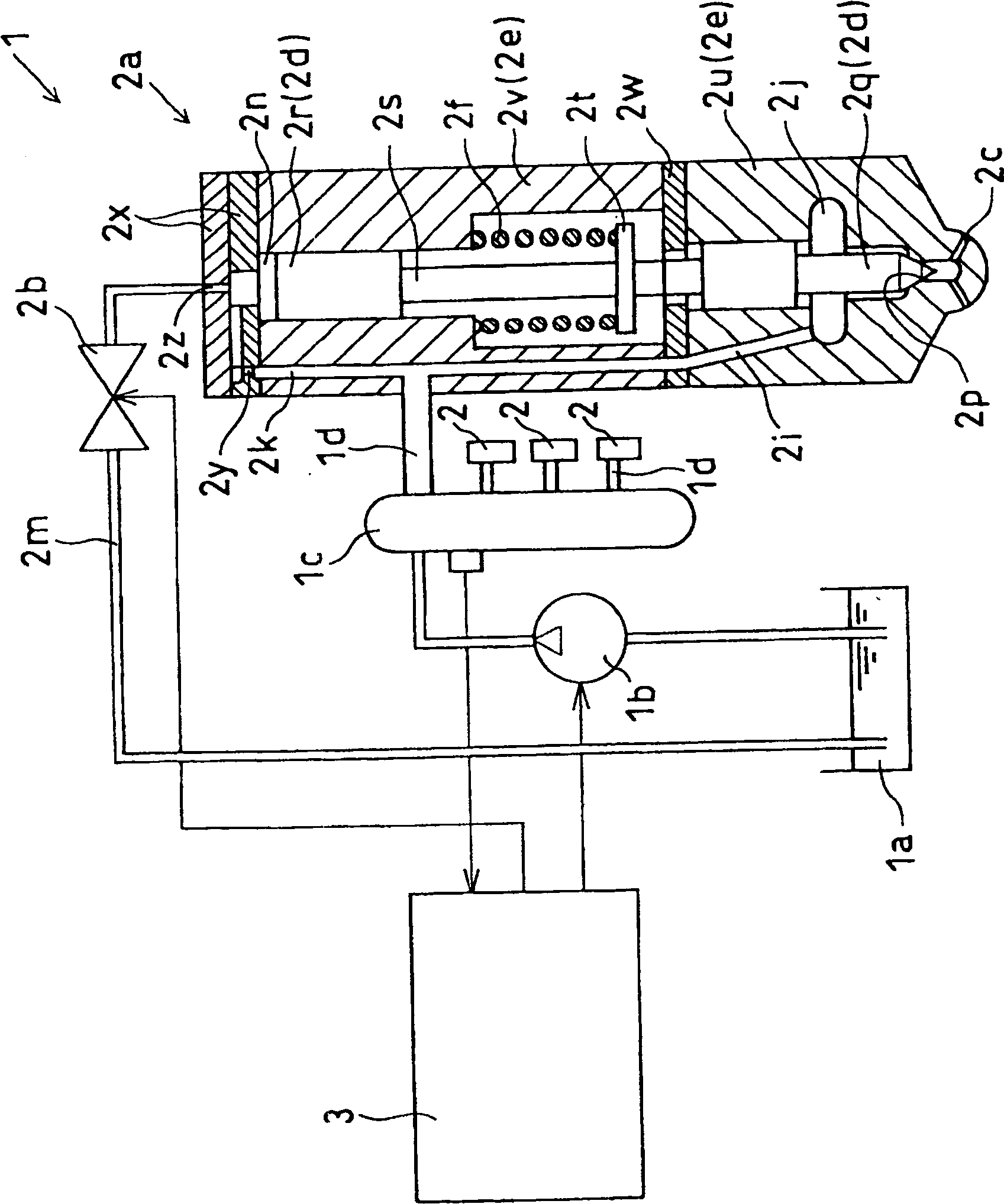

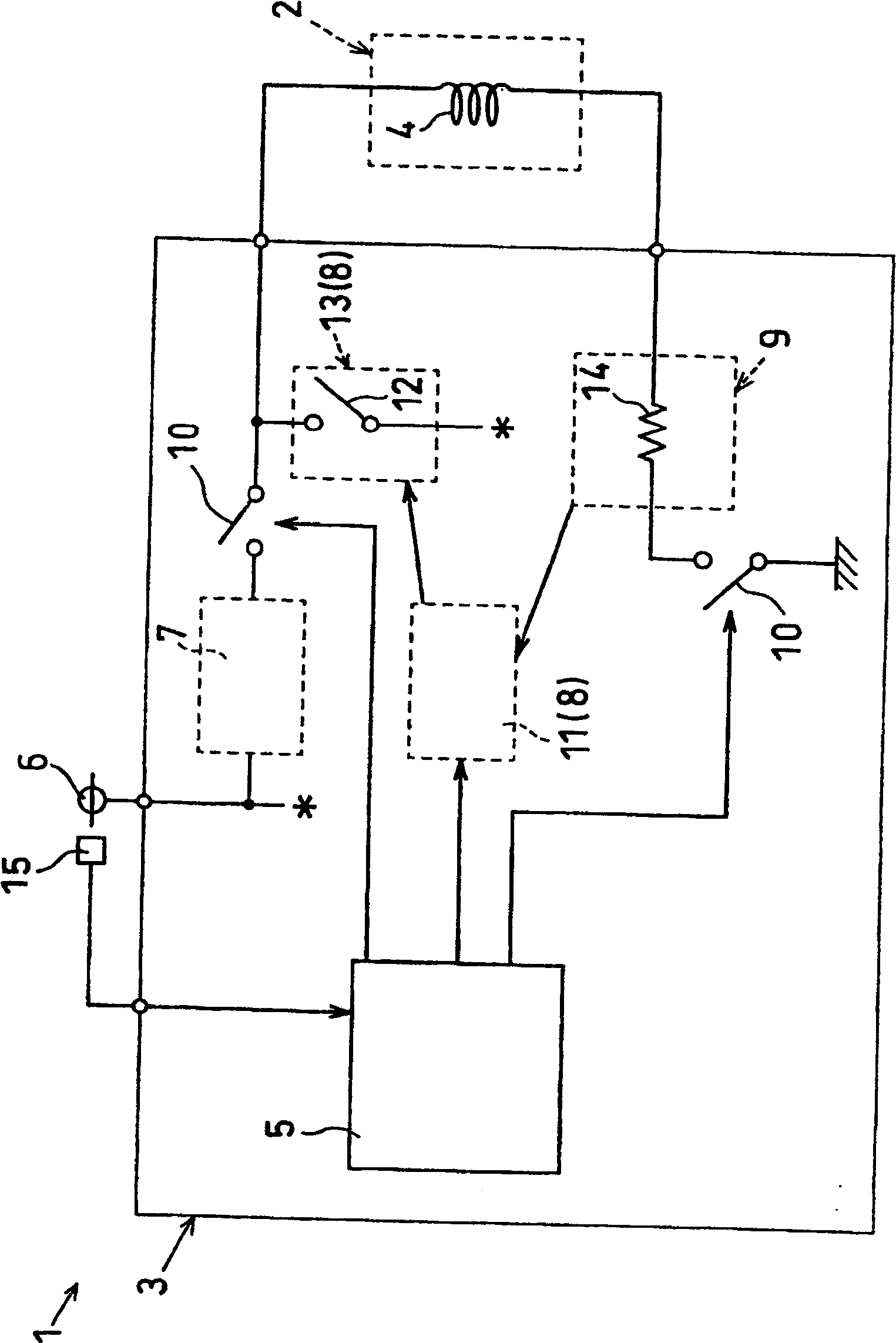

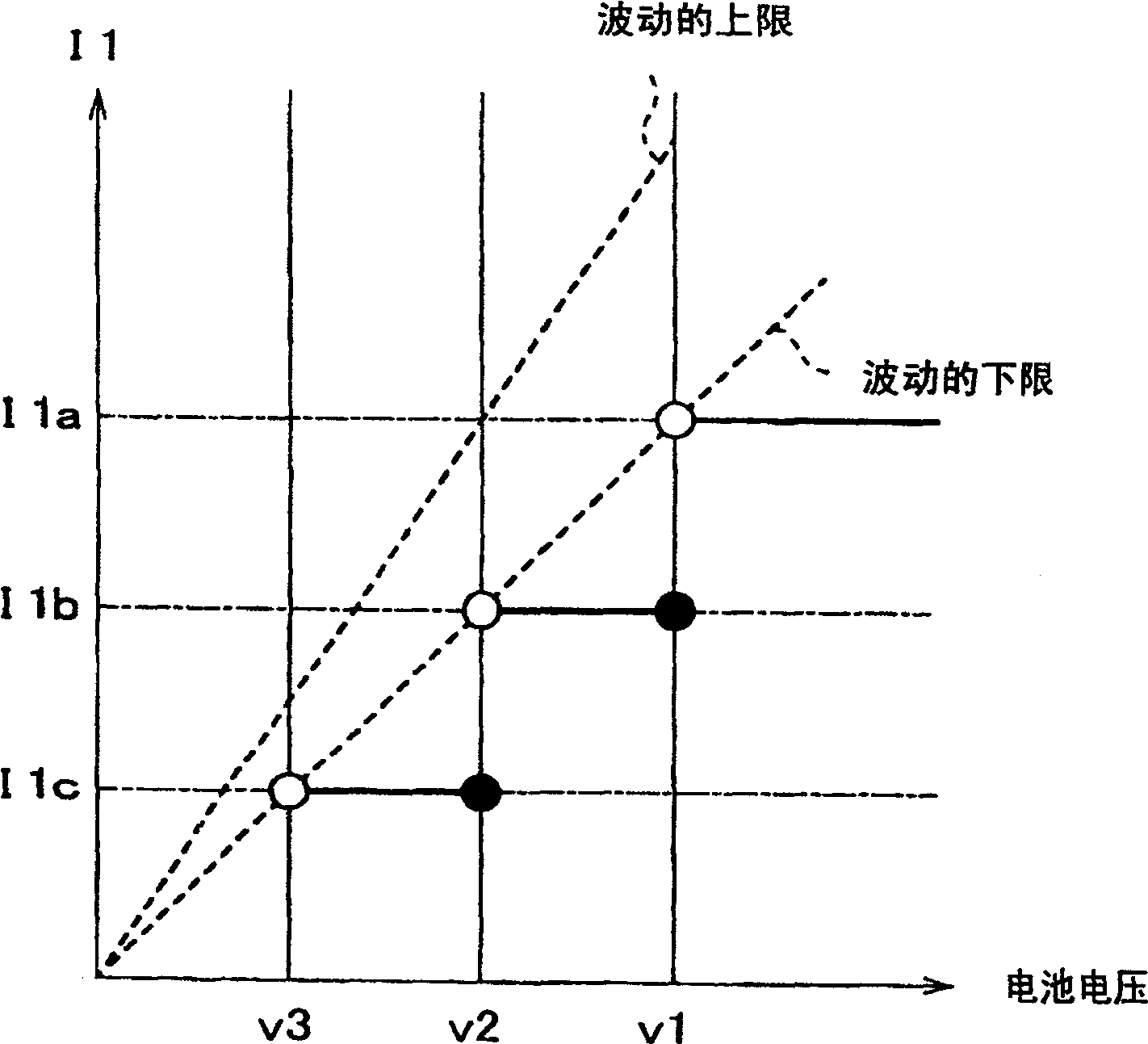

[0040] refer to figure 1 and 2 The fuel injection device of the first embodiment will be explained. The fuel injection device 1 is a device that supplies and injects fuel into each cylinder of a (4-cylinder) diesel engine (hereinafter also referred to as an engine). Such as figure 1 As shown, the engine includes: a fuel supply pump 1b, which sucks fuel from a fuel tank 1a and discharges high-pressure fuel; a common rail device 1c, which stores high-pressure fuel and controls fuel pressure with a common rail pressure, wherein the fuel is pressure to perform injection; a plurality of injectors 2, which are installed on each engine cylinder and inject high-pressure fuel into the corresponding cylinder; and an electronic control unit 3, which electronically controls the fuel supply pump 1b, the injector 2, etc. .

[0041] These injectors 2 are provided on the downstream side of the high-pressure fuel lines 1d branched from the common rail device 1c. The injector 2 includes:...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com