Plaiter structure

A cloth folding machine and cloth technology, applied in the direction of folder, folding thin material, laundry room device, etc., can solve the problems of uneconomical, unable to fold out cloth 40, unable to be effectively solved, etc., to achieve high cloth storage, large The effect of carrying space

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] Relevant preferred embodiment of the present invention and technical content, cooperate accompanying drawing to illustrate as follows now:

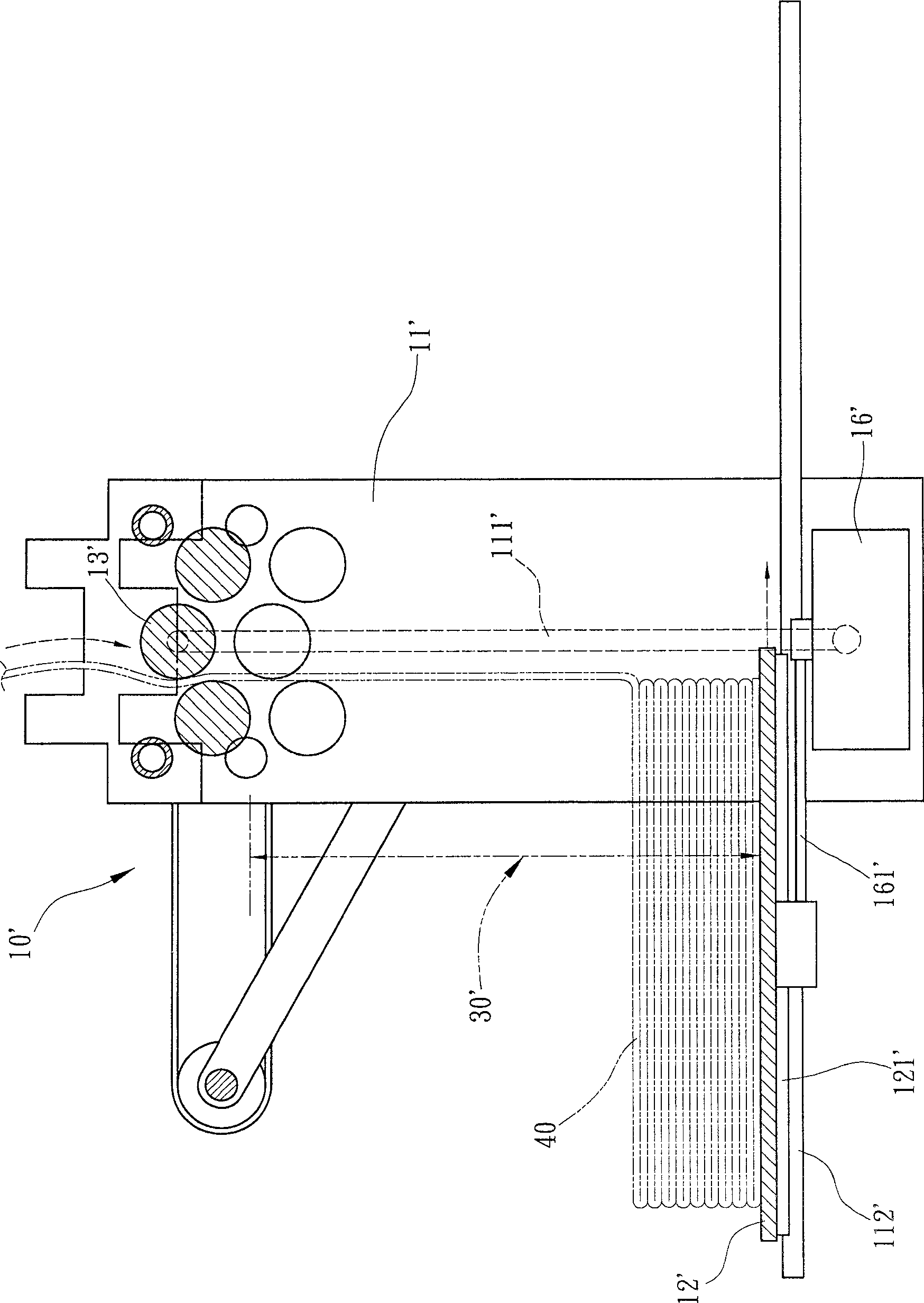

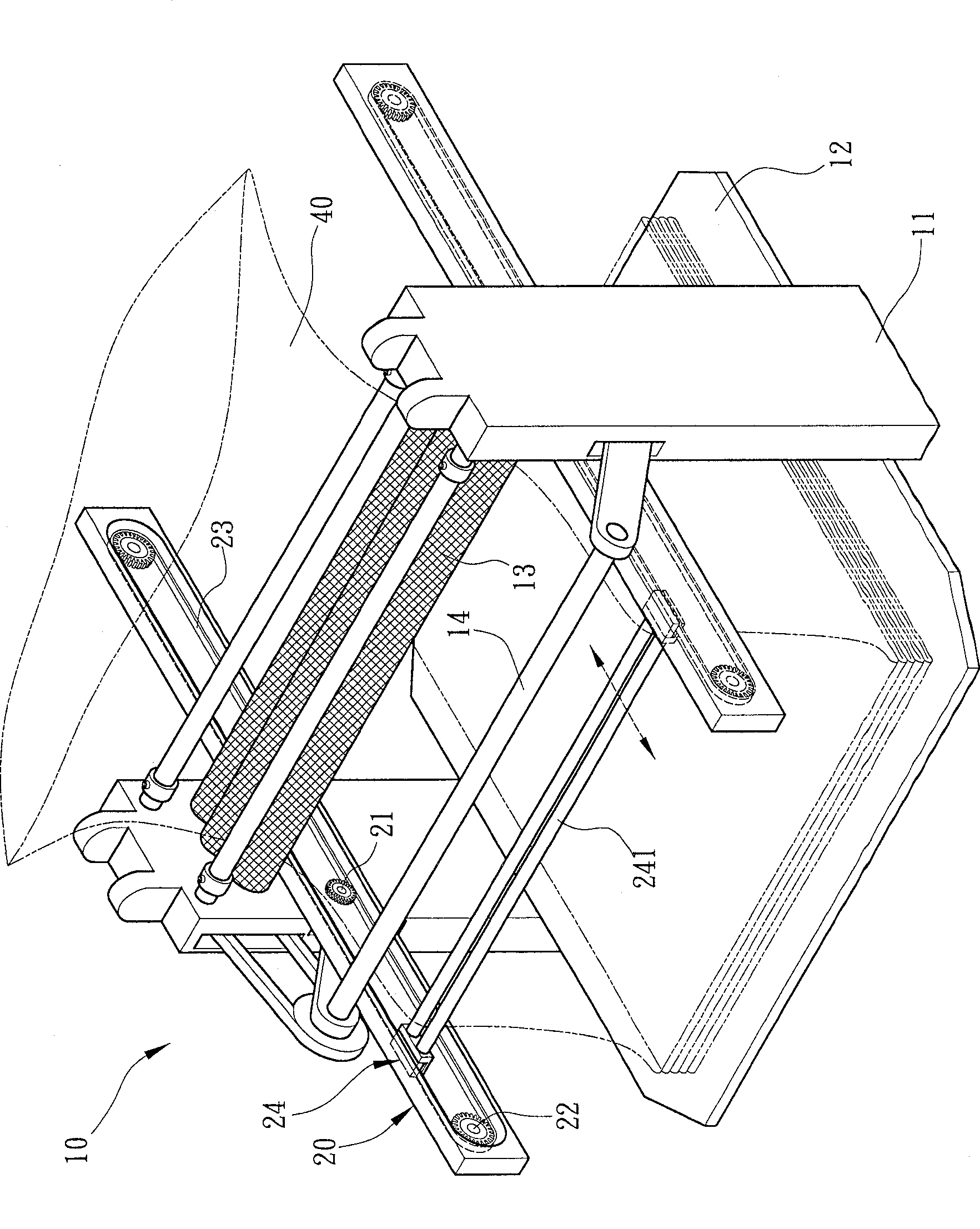

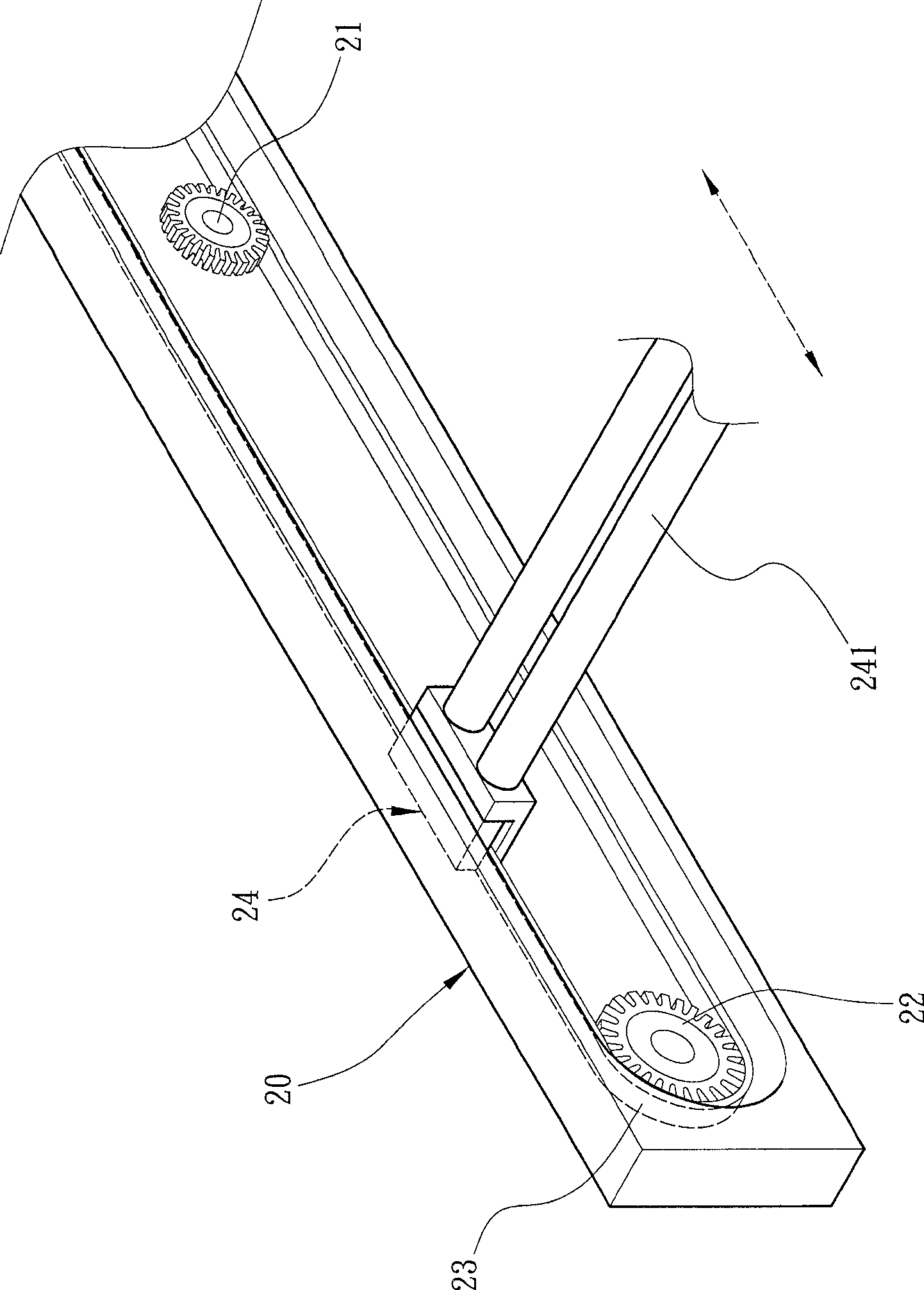

[0023] Please refer to figure 2 and image 3 Shown are the three-dimensional schematic diagram of the appearance of the fabric folding machine structure of the present invention and the three-dimensional schematic diagram of the partial appearance of the cloth folding unit. The structure of the cloth folding machine 10 of the present invention is applied to the folding mechanical structure of the cloth 40 woven by a circular knitting machine (not shown in the figure), the cloth folding machine 10 has a seat 12 that can carry the cloth 40, and The two ends of this bearing seat 12 are fixedly connected with the bottom ends of the two side seats 11, and at the upper end between the two side seats 11, there are many pieces of cloth 40 that can be flattened by the circular knitting machine for The cloth rolling rod 13 collected, in a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com